Pambuka produk

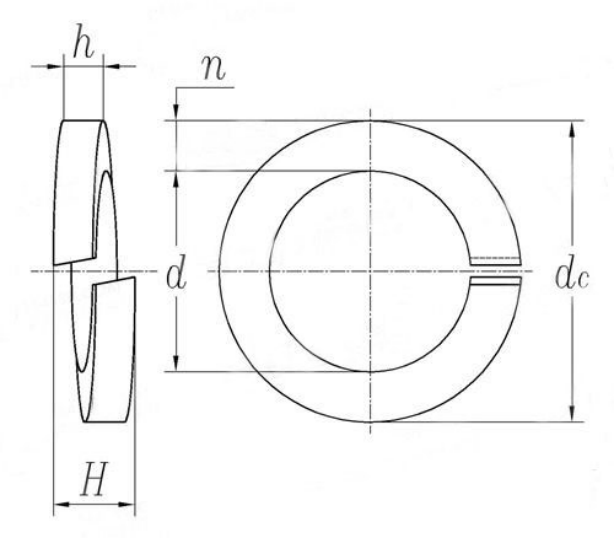

A ring pamisah ing siji titik lan mbengkongaken menyang wangun helical. Iki njalari mesin cuci kanggo ngetokake pasukan spring antarane sirah fastener lan landasan, kang njogo mesin cuci hard marang landasan lan thread bolt hard marang nut utawa substrat thread, nggawe gesekan liyane lan resistance kanggo rotasi. Standar sing ditrapake yaiku ASME B18.21.1, Saka 127 B, lan Standar Militer Amerika Serikat NASM 35338 (biyen MS 35338 lan AN-935).

Spring washers minangka heliks tangan kiwa lan ngidini benang diencerake ing arah tangan tengen mung, yaiku arah jarum jam. Nalika gerakan ngowahi tangan kiwa diterapake, pinggiran sing diunggahake bakal nyopot ing sisih ngisor bolt utawa nut lan bagean sing dipasang, saéngga nolak ngowahi. Mulane, spring washers ora efektif ing Utas tangan kiwa lan hardened lumahing. Uga, ora bisa digunakake bebarengan karo mesin cuci sing rata ing sangisore mesin cuci musim semi, amarga iki ngisolasi mesin cuci musim semi saka nresep menyang komponen sing ora bisa diowahi.

Keuntungan saka mesin cuci kunci spring dumunung ing wangun trapezoid saka mesin cuci. Nalika dikompres kanggo mbukak cedhak kekuatan bukti bolt, bakal corak lan flatten. Iki nyuda tingkat spring saka joint bolted sing ngidini kanggo njaga luwih pasukan ing tingkat geter padha. Iki nyegah loosening.

Aplikasi

The spring washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Different spring washers perform this function in slightly different ways, but the basic concept is to hold the nut and bolt in place. Some spring washers achieve this function by biting into the base material (bolt) and the nut with their ends.

Spring washers are commonly used in applications involving vibration and possible slippage of fasteners. Industries that commonly use spring washers are transportation related (automotive, aircraft, marine). Spring washers may also be used in household appliances such as air handlers and clothes washers (washing machines).

|

diameteripun nominal |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

(14) |

|

|

d |

regane paling sithik |

2.1 |

2.6 |

3.1 |

4.1 |

5.1 |

6.2 |

8.2 |

10.2 |

12.3 |

14.3 |

|

nilai crest |

2.3 |

2.8 |

3.3 |

4.4 |

5.4 |

6.7 |

8.7 |

10.7 |

12.8 |

14.9 |

|

|

h |

nominal |

0.6 |

0.8 |

1 |

1.2 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

|

regane paling sithik |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

|

nilai crest |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

n |

regane paling sithik |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

nilai crest |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

H |

regane paling sithik |

1.2 |

1.6 |

2 |

2.4 |

3.2 |

4 |

5 |

6 |

7 |

8 |

|

nilai crest |

1.5 |

2.1 |

2.6 |

3 |

4 |

5 |

6.5 |

8 |

9 |

10.5 |

|

|

Sewu lembar bobot (baja) kg |

0.023 |

0.053 |

0.097 |

0.182 |

0.406 |

0.745 |

1.53 |

2.82 |

4.63 |

6.85 |

|

|

diameteripun nominal |

16 |

(18) |

20 |

(22) |

24 |

(27) |

30 |

36 |

42 |

48 |

|

|

d |

regane paling sithik |

16.3 |

18.3 |

20.5 |

22.5 |

24.5 |

27.5 |

30.5 |

36.6 |

42.6 |

49 |

|

nilai crest |

16.9 |

19.1 |

21.3 |

23.3 |

25.5 |

28.5 |

31.5 |

37.8 |

43.8 |

50.2 |

|

|

h |

nominal |

4 |

4.5 |

5 |

5 |

6 |

6 |

6.5 |

7 |

8 |

9 |

|

regane paling sithik |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

|

nilai crest |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

n |

regane paling sithik |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

nilai crest |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

H |

regane paling sithik |

8 |

9 |

10 |

10 |

12 |

12 |

13 |

14 |

16 |

18 |

|

nilai crest |

10.5 |

11.5 |

13 |

13 |

15 |

15 |

17 |

18 |

21 |

23 |

|

|

Sewu lembar bobot (baja) kg |

7.75 |

11 |

15.2 |

16.5 |

26.2 |

28.2 |

37.6 |

51.8 |

78.7 |

114 |

|