Produkt Yntroduksje

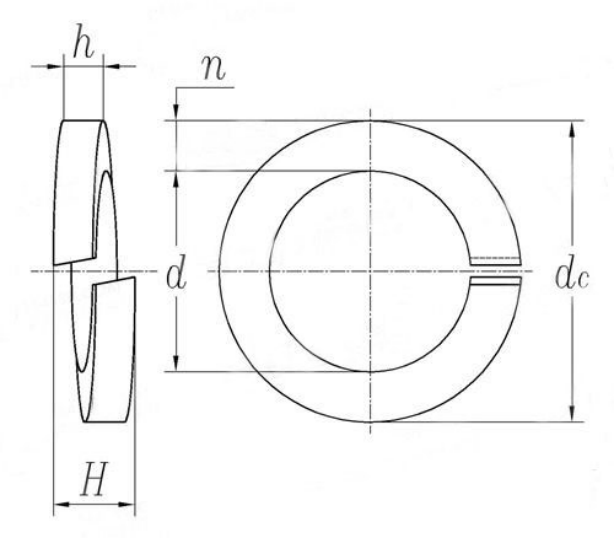

In ring spjalte op ien punt en bûgde yn in spiraalfoarm. Dit feroarsaket de waskmasine te oefenjen in spring krêft tusken de fastener syn holle en it substraat, dy't ûnderhâldt de waskmasine hurd tsjin it substraat en de bout tried hurd tsjin de moer of substraat tried, it meitsjen fan mear wriuwing en ferset tsjin rotaasje. Tapasbere noarmen binne LYKAS MY B18.21.1, FAN 127 B, en Feriene Steaten Militêre Standert NASM 35338 (earder MS 35338 en AN-935).

Spring washers binne in lofterhân helix en tastean de tried wurde oanskerpe yn in rjochterhân rjochting allinnich, dat wol sizze in klok yn rjochting. As in draaiende beweging fan 'e lofterhân wurdt tapast, byt de ferhege râne yn' e ûnderkant fan 'e bout of moer en it diel dêr't it is bolted oan, en ferset dus it draaien. Dêrom binne springwaskers net effektyf op linkse triedden en ferhurde oerflakken. Ek moatte se net brûkt wurde yn kombinaasje mei in platte waskmasine ûnder de springwasker, om't dit de springwasker isolearret fan byt yn 'e komponint dy't wjerstean sil.

It foardiel fan springslotwaskers leit yn 'e trapezoïdale foarm fan' e washer. As it wurdt komprimearre ta loads tichtby de bewiissterkte fan 'e bout, sil it draaie en flakke. Dit ferleget de maitiid fan 'e bolted joint wêrtroch it mear krêft kin behâlde ûnder deselde trillingsnivo's. Dit foarkomt losrinnen.

Oanfraach

The spring washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Different spring washers perform this function in slightly different ways, but the basic concept is to hold the nut and bolt in place. Some spring washers achieve this function by biting into the base material (bolt) and the nut with their ends.

Spring washers are commonly used in applications involving vibration and possible slippage of fasteners. Industries that commonly use spring washers are transportation related (automotive, aircraft, marine). Spring washers may also be used in household appliances such as air handlers and clothes washers (washing machines).

|

nominale diameter |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

(14) |

|

|

d |

minste wearde |

2.1 |

2.6 |

3.1 |

4.1 |

5.1 |

6.2 |

8.2 |

10.2 |

12.3 |

14.3 |

|

crest wearde |

2.3 |

2.8 |

3.3 |

4.4 |

5.4 |

6.7 |

8.7 |

10.7 |

12.8 |

14.9 |

|

|

h |

nominale |

0.6 |

0.8 |

1 |

1.2 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

|

minste wearde |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

|

crest wearde |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

n |

minste wearde |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

crest wearde |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

H |

minste wearde |

1.2 |

1.6 |

2 |

2.4 |

3.2 |

4 |

5 |

6 |

7 |

8 |

|

crest wearde |

1.5 |

2.1 |

2.6 |

3 |

4 |

5 |

6.5 |

8 |

9 |

10.5 |

|

|

Tûzen stikken gewicht (stiel) kg |

0.023 |

0.053 |

0.097 |

0.182 |

0.406 |

0.745 |

1.53 |

2.82 |

4.63 |

6.85 |

|

|

nominale diameter |

16 |

(18) |

20 |

(22) |

24 |

(27) |

30 |

36 |

42 |

48 |

|

|

d |

minste wearde |

16.3 |

18.3 |

20.5 |

22.5 |

24.5 |

27.5 |

30.5 |

36.6 |

42.6 |

49 |

|

crest wearde |

16.9 |

19.1 |

21.3 |

23.3 |

25.5 |

28.5 |

31.5 |

37.8 |

43.8 |

50.2 |

|

|

h |

nominale |

4 |

4.5 |

5 |

5 |

6 |

6 |

6.5 |

7 |

8 |

9 |

|

minste wearde |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

|

crest wearde |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

n |

minste wearde |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

crest wearde |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

H |

minste wearde |

8 |

9 |

10 |

10 |

12 |

12 |

13 |

14 |

16 |

18 |

|

crest wearde |

10.5 |

11.5 |

13 |

13 |

15 |

15 |

17 |

18 |

21 |

23 |

|

|

Tûzen stikken gewicht (stiel) kg |

7.75 |

11 |

15.2 |

16.5 |

26.2 |

28.2 |

37.6 |

51.8 |

78.7 |

114 |

|