Whakataki Hua

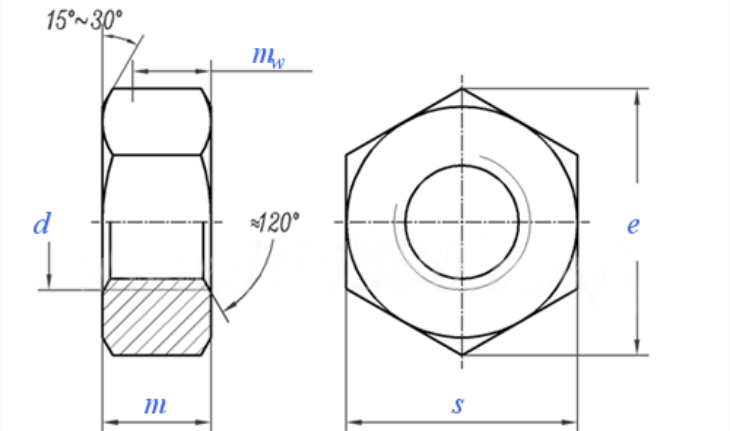

Ko te nati hex tetahi o nga nati tino noa e waatea ana, ka whakamahia me nga punga, nga raka, nga tira, nga tiu, nga rakau miro me etahi atu mea whakamau he miro wiri miihini. He poto te Hex mo te hexagon, ko te tikanga e ono nga taha.Hex n Ko nga uts e tata ana ki te hono tahi me te raka whakahiato ki te hono i nga wahanga maha. Ka noho tahi nga hoa e rua ma te whakakotahitanga o te waku o o raua miro (he paku rerekee te ahua), he iti te toronga o te raka, me te kopiri o nga waahanga. kia hui tahi.

Kia mau tonu te urunga o te miro ki te nati hex, me roa rawa te roa o nga tutaki/tiukiri kia rua nga miro ki te toro atu ki tua atu o te mata nati i muri i te whakakiki. kia mohio ka taea te kati tika te nati.

Nga tono

Ka taea te whakamahi nati Hex mo te maha o nga tono rereke e mau ana i te rakau, te rino, me etahi atu mea hanga mo nga kaupapa penei i nga tauranga, piriti, hanganga huarahi, me nga whare.

Black-oxide steel screws are mildly corrosion resistant in dry environments.Zinc-plated steel screws resist corrosion in wet environments.Black ultra-corrosion-resistant-coated steel screws resist chemicals and withstand 1,000 hours of salt spray .Coarse threads are the industry standard; choose these Hex nuts if you don’t know the threads per inch.Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance.

The Hex nuts is designed to fit a ratchet or spanner torque wrenches allowing you to tighten the nuts to your exact specifications.Grade 2 bolts tend to be used in construction for joining wood components.Grade 4.8 bolt s are used in small engines.Grade 8.8 10.9 or 12.9 bolt s provide high tensile strength.One advantage nuts fasteners have over welds or rivets is that they allow for easy disassembly for repairs and maintenance.

|

Rahi miro d |

M1

|

M1.2

|

M1.4

|

M1.6

|

(M1.7)

|

M2

|

(M2.3)

|

M2.5

|

(M2.6)

|

M3

|

(M3.5)

|

M4

|

M5

|

M6

|

(M7)

|

M8

|

||||||||||||||||||

|

P |

pitch |

miro taratara |

0.25 |

0.25 |

0.3 |

0.35 |

0.35 |

0.4 |

0.45 |

0.45 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

||||||||||||||||

|

tata-whakatangi |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

1 |

||||||||||||||||||

|

tata-whakatangi |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

||||||||||||||||||

|

m |

Mōrahi = nominal |

0.8 |

1 |

1.2 |

1.3 |

1.4 |

1.6 |

1.8 |

2 |

2 |

2.4 |

2.8 |

3.2 |

4 |

5 |

5.5 |

6.5 |

|||||||||||||||||

|

iti rawa te uara |

0.55 |

0.75 |

0.95 |

1.05 |

1.15 |

1.35 |

1.55 |

1.75 |

1.75 |

2.15 |

2.55 |

2.9 |

3.7 |

4.7 |

5.2 |

6.14 |

||||||||||||||||||

|

mw |

iti rawa te uara |

0.44 |

0.6 |

0.76 |

0.84 |

0.92 |

1.08 |

1.24 |

1.4 |

1.4 |

1.72 |

2.04 |

2.32 |

2.96 |

3.76 |

4.16 |

4.91 |

|||||||||||||||||

|

s |

Mōrahi = nominal |

2.5 |

3 |

3 |

3.2 |

3.5 |

4 |

4.5 |

5 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

|||||||||||||||||

|

iti rawa te uara |

2.4 |

2.9 |

2.9 |

3.02 |

3.38 |

3.82 |

4.32 |

4.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

||||||||||||||||||

|

e ① |

iti rawa te uara |

2.71 |

3.28 |

3.28 |

3.41 |

3.82 |

4.32 |

4.88 |

5.45 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

|||||||||||||||||

|

* |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

|

He mano nga pihi taumaha (te rino) kg |

0.03 |

0.054 |

0.063 |

0.076 |

0.1 |

0.142 |

0.2 |

0.28 |

0.72 |

0.384 |

0.514 |

0.81 |

1.23 |

2.5 |

3.12 |

5.2 |

||||||||||||||||||

|

Rahi miro d |

M10

|

M12

|

(M14)

|

M16

|

(M18)

|

M20

|

(M22)

|

M24

|

(M27)

|

M30

|

(M33)

|

M36

|

(M39)

|

M42

|

(M45)

|

M48

|

||||||||||||||||||

|

P |

pitch |

miro taratara |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

4.5 |

5 |

||||||||||||||||

|

tata-whakatangi |

1 |

1.5 |

1.5 |

1.5 |

1.5 |

2 |

1.5 |

2 |

2 |

2 |

2 |

3 |

3 |

3 |

3 |

3 |

||||||||||||||||||

|

tata-whakatangi |

1.25 |

1.25 |

/ |

/ |

2 |

1.5 |

2 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

||||||||||||||||||

|

m |

Mōrahi = nominal |

8 |

10 |

11 |

13 |

15 |

16 |

18 |

19 |

22 |

24 |

26 |

29 |

31 |

34 |

36 |

38 |

|||||||||||||||||

|

iti rawa te uara |

7.64 |

9.64 |

10.3 |

12.3 |

14.3 |

14.9 |

16.9 |

17.7 |

20.7 |

22.7 |

24.7 |

27.4 |

29.4 |

32.4 |

34.4 |

36.4 |

||||||||||||||||||

|

mw |

iti rawa te uara |

6.11 |

7.71 |

8.24 |

9.84 |

11.44 |

11.92 |

13.52 |

14.16 |

16.56 |

18.16 |

19.76 |

21.92 |

23.52 |

25.9 |

27.5 |

29.1 |

|||||||||||||||||

|

s |

Mōrahi = nominal |

17 |

19 |

22 |

24 |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

|||||||||||||||||

|

iti rawa te uara |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

29.16 |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

68.1 |

73.1 |

||||||||||||||||||

|

e ① |

iti rawa te uara |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

32.95 |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

76.95 |

82.6 |

|||||||||||||||||

|

* |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

|

He mano nga pihi taumaha (te rino) kg |

11.6 |

17.3 |

25 |

33.3 |

49.4 |

64.4 |

79 |

110 |

165 |

223 |

288 |

393 |

502 |

652 |

800 |

977 |

||||||||||||||||||

|

Rahi miro d |

(M52) |

M56 |

(M60) |

M64 |

(M68) |

M72 |

(M76) |

M80 |

(M85) |

M90 |

M100 |

M110 |

M125 |

M140 |

M160 |

|||||||||||||||||||

|

P |

pitch |

miro taratara |

5 |

5.5 |

5.5 |

6 |

6 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||||||||||||||

|

tata-whakatangi |

3 |

4 |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

|||||||||||||||||||

|

tata-whakatangi |

/ |

/ |

/ |

/ |

/ |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

/ |

/ |

|||||||||||||||||||

|

m |

Mōrahi = nominal |

42 |

45 |

48 |

51 |

54 |

58 |

61 |

64 |

68 |

72 |

80 |

88 |

100 |

112 |

128 |

||||||||||||||||||

|

iti rawa te uara |

40.4 |

43.4 |

46.4 |

49.1 |

52.1 |

56.1 |

59.1 |

62.1 |

66.1 |

70.1 |

78.1 |

85.8 |

97.8 |

109.8 |

125.5 |

|||||||||||||||||||

|

mw |

iti rawa te uara |

32.3 |

34.7 |

37.1 |

39.3 |

41.7 |

44.9 |

47.3 |

49.7 |

52.9 |

56.1 |

62.5 |

68.6 |

78.2 |

87.8 |

100 |

||||||||||||||||||

|

s |

Mōrahi = nominal |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

115 |

120 |

130 |

145 |

155 |

180 |

200 |

230 |

||||||||||||||||||

|

iti rawa te uara |

78.1 |

82.8 |

87.8 |

92.8 |

97.8 |

102.8 |

107.8 |

112.8 |

117.8 |

127.5 |

142.5 |

152.5 |

177.5 |

195.4 |

225.4 |

|||||||||||||||||||

|

e ① |

iti rawa te uara |

|

88.25 |

93.56 |

99.21 |

104.86 |

110.51 |

116.16 |

121.81 |

127.46 |

133.11 |

144.08 |

161.02 |

172.32 |

200.57 |

220.8 |

254.7 |

|||||||||||||||||

|

* |

|

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

170 |

196 |

216 |

248 |

||||||||||||||||||

|

He mano nga pihi taumaha (te rino) kg

|

1220 |

1420 |

1690 |

1980 |

2300 |

2670 |

3040 |

3440 |

3930 |

4930 |

6820 |

8200 |

13000 |

17500 |

26500 |

|||||||||||||||||||