Okwu Mmalite ngwaahịa

Mkpụrụ osisi hex bụ otu n'ime mkpụrụ osisi a na-ahụkarị ma jiri arịlịka, bolts, skru, studs, threaded sticks na na ihe ọ bụla ọzọ nke nwere igwe screw threads.Hex dị mkpụmkpụ maka hexagon, nke pụtara na ha nwere akụkụ isii. Ọ fọrọ nke nta ka ọ bụrụ na a na-eji uts eme ihe mgbe niile na njikọ nke mating na-ejikọta ọtụtụ akụkụ ọnụ. A na-ejikọta ndị mmekọ abụọ ahụ site na nchikota nke esemokwu nke eriri ha (ya na obere nrụrụ na-agbanwe), ntakịrị mgbatị nke bolt, na mkpakọ nke akụkụ ahụ. a ga-ejide ọnụ.

Iji hụ na njikọ aka zuru ezu na eriri hex, bolts / screws kwesịrị ịdị ogologo oge iji kwe ka ọ dịkarịa ala eriri abụọ zuru ezu gbasaa n'ihu ihu nut mgbe ọ gbasasịrị. jide n'aka na enwere ike imechi akị nke ọma.

Ngwa

Enwere ike iji mkpụrụ osisi hex maka ọtụtụ ngwa dị iche iche gụnyere itinye osisi, nchara, na ihe ndị ọzọ owuwu maka ọrụ dịka docks, àkwà mmiri, ihe owuwu okporo ụzọ, na ụlọ.

Black-oxide steel screws are mildly corrosion resistant in dry environments.Zinc-plated steel screws resist corrosion in wet environments.Black ultra-corrosion-resistant-coated steel screws resist chemicals and withstand 1,000 hours of salt spray .Coarse threads are the industry standard; choose these Hex nuts if you don’t know the threads per inch.Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance.

The Hex nuts is designed to fit a ratchet or spanner torque wrenches allowing you to tighten the nuts to your exact specifications.Grade 2 bolts tend to be used in construction for joining wood components.Grade 4.8 bolt s are used in small engines.Grade 8.8 10.9 or 12.9 bolt s provide high tensile strength.One advantage nuts fasteners have over welds or rivets is that they allow for easy disassembly for repairs and maintenance.

|

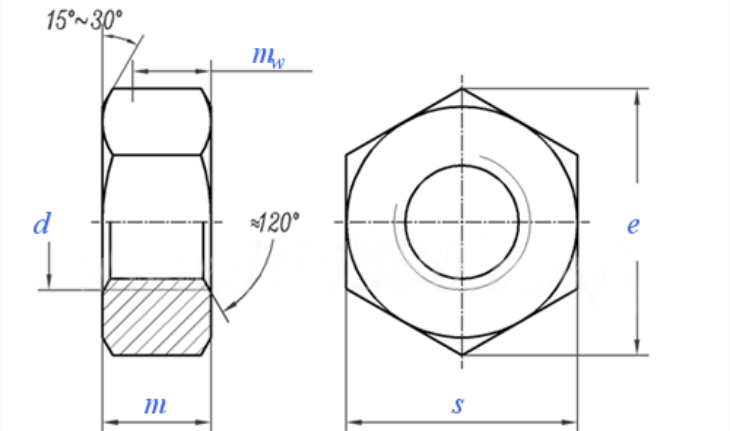

Nha eriri d |

M1

|

M1.2

|

M1.4

|

M1.6

|

(M1.7)

|

M2

|

(M2.3)

|

M2.5

|

(M2.6)

|

M3

|

(M3.5)

|

M4

|

M5

|

M6

|

(M7)

|

M8

|

||||||||||||||||||

|

P |

pitch |

eri siri ike |

0.25 |

0.25 |

0.3 |

0.35 |

0.35 |

0.4 |

0.45 |

0.45 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

1.25 |

||||||||||||||||

|

chiri anya-gbara |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

1 |

||||||||||||||||||

|

chiri anya-gbara |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

||||||||||||||||||

|

m |

Nke kacha = ọnụ ọgụgụ |

0.8 |

1 |

1.2 |

1.3 |

1.4 |

1.6 |

1.8 |

2 |

2 |

2.4 |

2.8 |

3.2 |

4 |

5 |

5.5 |

6.5 |

|||||||||||||||||

|

uru kacha nta |

0.55 |

0.75 |

0.95 |

1.05 |

1.15 |

1.35 |

1.55 |

1.75 |

1.75 |

2.15 |

2.55 |

2.9 |

3.7 |

4.7 |

5.2 |

6.14 |

||||||||||||||||||

|

mw |

uru kacha nta |

0.44 |

0.6 |

0.76 |

0.84 |

0.92 |

1.08 |

1.24 |

1.4 |

1.4 |

1.72 |

2.04 |

2.32 |

2.96 |

3.76 |

4.16 |

4.91 |

|||||||||||||||||

|

s |

Nke kacha = ọnụ ọgụgụ |

2.5 |

3 |

3 |

3.2 |

3.5 |

4 |

4.5 |

5 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

13 |

|||||||||||||||||

|

uru kacha nta |

2.4 |

2.9 |

2.9 |

3.02 |

3.38 |

3.82 |

4.32 |

4.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

12.73 |

||||||||||||||||||

|

e ① |

uru kacha nta |

2.71 |

3.28 |

3.28 |

3.41 |

3.82 |

4.32 |

4.88 |

5.45 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

14.38 |

|||||||||||||||||

|

* |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

|

Puku iberibe arọ (steel) n'arọ |

0.03 |

0.054 |

0.063 |

0.076 |

0.1 |

0.142 |

0.2 |

0.28 |

0.72 |

0.384 |

0.514 |

0.81 |

1.23 |

2.5 |

3.12 |

5.2 |

||||||||||||||||||

|

Nha eriri d |

M10

|

M12

|

(M14)

|

M16

|

(M18)

|

M20

|

(M22)

|

M24

|

(M27)

|

M30

|

(M33)

|

M36

|

(M39)

|

M42

|

(M45)

|

M48

|

||||||||||||||||||

|

P |

pitch |

eri siri ike |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

4.5 |

5 |

||||||||||||||||

|

chiri anya-gbara |

1 |

1.5 |

1.5 |

1.5 |

1.5 |

2 |

1.5 |

2 |

2 |

2 |

2 |

3 |

3 |

3 |

3 |

3 |

||||||||||||||||||

|

chiri anya-gbara |

1.25 |

1.25 |

/ |

/ |

2 |

1.5 |

2 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

||||||||||||||||||

|

m |

Nke kacha = ọnụ ọgụgụ |

8 |

10 |

11 |

13 |

15 |

16 |

18 |

19 |

22 |

24 |

26 |

29 |

31 |

34 |

36 |

38 |

|||||||||||||||||

|

uru kacha nta |

7.64 |

9.64 |

10.3 |

12.3 |

14.3 |

14.9 |

16.9 |

17.7 |

20.7 |

22.7 |

24.7 |

27.4 |

29.4 |

32.4 |

34.4 |

36.4 |

||||||||||||||||||

|

mw |

uru kacha nta |

6.11 |

7.71 |

8.24 |

9.84 |

11.44 |

11.92 |

13.52 |

14.16 |

16.56 |

18.16 |

19.76 |

21.92 |

23.52 |

25.9 |

27.5 |

29.1 |

|||||||||||||||||

|

s |

Nke kacha = ọnụ ọgụgụ |

17 |

19 |

22 |

24 |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

|||||||||||||||||

|

uru kacha nta |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

29.16 |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.1 |

68.1 |

73.1 |

||||||||||||||||||

|

e ① |

uru kacha nta |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

32.95 |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

76.95 |

82.6 |

|||||||||||||||||

|

* |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||||||||

|

Puku iberibe arọ (steel) n'arọ |

11.6 |

17.3 |

25 |

33.3 |

49.4 |

64.4 |

79 |

110 |

165 |

223 |

288 |

393 |

502 |

652 |

800 |

977 |

||||||||||||||||||

|

Nha eriri d |

(M52) |

M56 |

(M60) |

M64 |

(M68) |

M72 |

(M76) |

M80 |

(M85) |

M90 |

M100 |

M110 |

M125 |

M140 |

M160 |

|||||||||||||||||||

|

P |

pitch |

eri siri ike |

5 |

5.5 |

5.5 |

6 |

6 |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|||||||||||||||||

|

chiri anya-gbara |

3 |

4 |

4 |

4 |

4 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

|||||||||||||||||||

|

chiri anya-gbara |

/ |

/ |

/ |

/ |

/ |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

/ |

/ |

|||||||||||||||||||

|

m |

Nke kacha = ọnụ ọgụgụ |

42 |

45 |

48 |

51 |

54 |

58 |

61 |

64 |

68 |

72 |

80 |

88 |

100 |

112 |

128 |

||||||||||||||||||

|

uru kacha nta |

40.4 |

43.4 |

46.4 |

49.1 |

52.1 |

56.1 |

59.1 |

62.1 |

66.1 |

70.1 |

78.1 |

85.8 |

97.8 |

109.8 |

125.5 |

|||||||||||||||||||

|

mw |

uru kacha nta |

32.3 |

34.7 |

37.1 |

39.3 |

41.7 |

44.9 |

47.3 |

49.7 |

52.9 |

56.1 |

62.5 |

68.6 |

78.2 |

87.8 |

100 |

||||||||||||||||||

|

s |

Nke kacha = ọnụ ọgụgụ |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

115 |

120 |

130 |

145 |

155 |

180 |

200 |

230 |

||||||||||||||||||

|

uru kacha nta |

78.1 |

82.8 |

87.8 |

92.8 |

97.8 |

102.8 |

107.8 |

112.8 |

117.8 |

127.5 |

142.5 |

152.5 |

177.5 |

195.4 |

225.4 |

|||||||||||||||||||

|

e ① |

uru kacha nta |

|

88.25 |

93.56 |

99.21 |

104.86 |

110.51 |

116.16 |

121.81 |

127.46 |

133.11 |

144.08 |

161.02 |

172.32 |

200.57 |

220.8 |

254.7 |

|||||||||||||||||

|

* |

|

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

170 |

196 |

216 |

248 |

||||||||||||||||||

|

Puku iberibe arọ (steel) n'arọ

|

1220 |

1420 |

1690 |

1980 |

2300 |

2670 |

3040 |

3440 |

3930 |

4930 |

6820 |

8200 |

13000 |

17500 |

26500 |

|||||||||||||||||||