Product Introduction

A ring split at one point and bent into a helical shape. This causes the washer to exert a spring force between the fastener's head and the substrate, which maintains the washer hard against the substrate and the bolt thread hard against the nut or substrate thread, creating more friction and resistance to rotation. Applicable standards are ASME B18.21.1, DIN 127 B, and United States Military Standard NASM 35338 (formerly MS 35338 and AN-935).

Spring washers are a left hand helix and allow the thread to be tightened in a right hand direction only, i.e. a clockwise direction. When a left hand turning motion is applied, the raised edge bites into the underside of the bolt or nut and the part that it is bolted to, thus resisting turning. Therefore, spring washers are ineffective on left hand threads and hardened surfaces. Also, they are not to be used in conjunction with a flat washer under the spring washer, as this isolates the spring washer from biting into the component that will resist turning.

The benefit of spring lock washers lies in the trapezoidal shape of the washer. When compressed to loads near the proof strength of the bolt, it will twist and flatten. This reduces the spring rate of the bolted joint which allows it to maintain more force under the same vibration levels. This prevents loosening.

Applications

The spring washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Different spring washers perform this function in slightly different ways, but the basic concept is to hold the nut and bolt in place. Some spring washers achieve this function by biting into the base material (bolt) and the nut with their ends.

Spring washers are commonly used in applications involving vibration and possible slippage of fasteners. Industries that commonly use spring washers are transportation related (automotive, aircraft, marine). Spring washers may also be used in household appliances such as air handlers and clothes washers (washing machines).

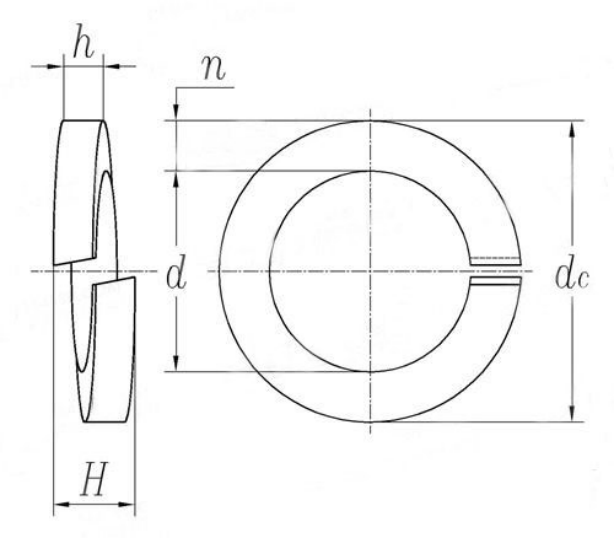

|

nominal diameter |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

(14) |

|

|

d |

least value |

2.1 |

2.6 |

3.1 |

4.1 |

5.1 |

6.2 |

8.2 |

10.2 |

12.3 |

14.3 |

|

crest value |

2.3 |

2.8 |

3.3 |

4.4 |

5.4 |

6.7 |

8.7 |

10.7 |

12.8 |

14.9 |

|

|

h |

nominal |

0.6 |

0.8 |

1 |

1.2 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

|

least value |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

|

crest value |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

n |

least value |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

crest value |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

H |

least value |

1.2 |

1.6 |

2 |

2.4 |

3.2 |

4 |

5 |

6 |

7 |

8 |

|

crest value |

1.5 |

2.1 |

2.6 |

3 |

4 |

5 |

6.5 |

8 |

9 |

10.5 |

|

|

Thousand pieces of weight (steel) kg |

0.023 |

0.053 |

0.097 |

0.182 |

0.406 |

0.745 |

1.53 |

2.82 |

4.63 |

6.85 |

|

|

nominal diameter |

16 |

(18) |

20 |

(22) |

24 |

(27) |

30 |

36 |

42 |

48 |

|

|

d |

least value |

16.3 |

18.3 |

20.5 |

22.5 |

24.5 |

27.5 |

30.5 |

36.6 |

42.6 |

49 |

|

crest value |

16.9 |

19.1 |

21.3 |

23.3 |

25.5 |

28.5 |

31.5 |

37.8 |

43.8 |

50.2 |

|

|

h |

nominal |

4 |

4.5 |

5 |

5 |

6 |

6 |

6.5 |

7 |

8 |

9 |

|

least value |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

|

crest value |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

n |

least value |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

crest value |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

H |

least value |

8 |

9 |

10 |

10 |

12 |

12 |

13 |

14 |

16 |

18 |

|

crest value |

10.5 |

11.5 |

13 |

13 |

15 |

15 |

17 |

18 |

21 |

23 |

|

|

Thousand pieces of weight (steel) kg |

7.75 |

11 |

15.2 |

16.5 |

26.2 |

28.2 |

37.6 |

51.8 |

78.7 |

114 |

|