Product Introduction

Flat washers are used to increase the bearing surface of a nut or fastener's head thus spreading the clamping force over a larger area. They can be useful when working with soft materials and oversized or irregular shaped holes.

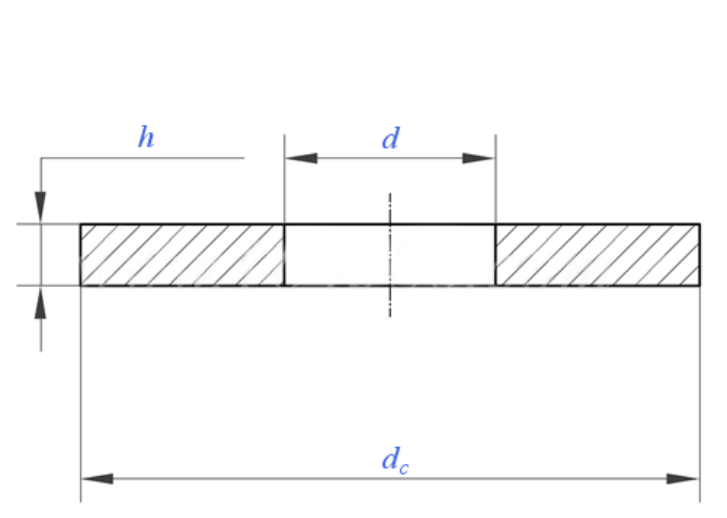

Washer size refers to its nominal hole size and is based on screw size. Its outside diameter (OD) is always larger. Size and OD are usually specified in fractional inches, although decimal inches may be used instead. Thickness is typically listed in decimal inches although we often convert it to fractional inches for convenience.

Grade 2 flat washers should only be used with Grade 2 hex cap screws (hex bolts)—use hardened flat washers with Grade 5 and 8 cap screws. Because Grade 2 flat washers are made of soft, low carbon steel, they will "yield" (compress, cup, bend, etc.) under the higher torque values normally associated with Grade 5 and 8 cap screws. As a result, there will be a reduction in clamping force as the washer yields.

Flat washers are commonly available in a variety of materials including aluminum, brass, nylon, silicon bronze, stainless steel and steel. Unplated or uncoated steel, referred to as "plain finish," has not been surface treated to prevent rust other than a light coating of oil for temporary protection. Consequently, common finishes for steel are zinc plating and hot dip galvanizing.

Applications

Through their design, the distribution property of plain washers can prevent any sort of damage to the assembled surfaces. Flat washer has a thin and flat surface with a hole in the centre. This type of washer provides support to a smaller head screw.

Black-oxide steel washers are mildly corrosion resistant in dry environments. Zinc-plated steel washers resist corrosion in wet environments. Black ultra-corrosion-resistant-coated steel washers resist chemicals and withstand 1,000 hours of salt spray.

|

specifications |

Φ1 |

Φ1.2 |

Φ1.4 |

Φ1.6 |

Φ2 |

Φ2.5 |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

Φ8 |

Φ10 |

||

|

d |

crest value |

1.22 |

1.42 |

1.62 |

1.82 |

2.32 |

2.82 |

3.36 |

4.36 |

5.46 |

6.6 |

8.6 |

10.74 |

|

|

least value |

1.1 |

1.3 |

1.5 |

1.7 |

2.2 |

2.7 |

3.2 |

4.2 |

5.3 |

6.4 |

8.4 |

10.5 |

||

|

dc |

crest value |

3 |

3.2 |

3.5 |

4 |

5 |

6.5 |

7 |

9 |

10 |

12.5 |

17 |

21 |

|

|

least value |

2.75 |

2.9 |

3.2 |

3.7 |

4.7 |

6.14 |

6.64 |

8.64 |

9.64 |

12.07 |

16.57 |

20.48 |

||

|

h |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

0.5 |

0.5 |

0.8 |

0.8 |

1.5 |

1.5 |

2 |

||

|

Thousand pieces of weight (steel) kg |

0.0014 |

0.0016 |

0.018 |

0.024 |

0.037 |

0.108 |

0.12 |

0.308 |

0.354 |

1.066 |

2.021 |

4.078 |

||

|

specifications |

Φ12 |

(Φ14) |

Φ16 |

(Φ18) |

Φ20 |

(Φ22) |

Φ24 |

(Φ27) |

Φ30 |

Φ36 |

Φ42 |

Φ48 |

||

|

d |

crest value |

13.24 |

15.24 |

17.24 |

19.28 |

21.28 |

23.28 |

25.28 |

28.28 |

31.34 |

37.34 |

43.34 |

50.34 |

|

|

least value |

13 |

15 |

17 |

19 |

21 |

23 |

25 |

28 |

31 |

37 |

43 |

50 |

||

|

dc |

crest value |

24 |

28 |

30 |

34 |

37 |

39 |

44 |

50 |

56 |

66 |

78 |

92 |

|

|

least value |

|

23.48 |

27.48 |

29.48 |

33.38 |

36.38 |

38.38 |

43.38 |

49.38 |

55.26 |

65.26 |

77.26 |

91.13 |

|

|

h |

2 |

2 |

3 |

3 |

3 |

3 |

4 |

4 |

4 |

5 |

7 |

8 |

||

|

Thousand pieces of weight (steel) kg |

5.018 |

6.892 |

11.3 |

14.7 |

17.16 |

18.42 |

32.33 |

42.32 |

53.64 |

92.07 |

182.8 |

294.1 |

||