Product Introduction

Metric Lock Nuts all have a feature that creates a non-permanent "locking" action. Prevailing Torque Lock Nuts rely upon thread deformation and must be wrenched on and off; they are not chemical and temperature limited like Nylon Insert Lock Nuts but reuse is still limited. K-Lock Nuts are free-spinning and reusable. Reuse of Nylon Insert Lock Nuts is limited and the captive nylon insert is susceptible to damage by certain chemicals and temperature extremes; wrenching the nut on and off is also required. Zinc plated steel nuts up to Class 10 and stainless steel with coarse and fine machine screw threads can be supplied.

Get a grip on metric bolts exposed to vibration, wear, and changes in temperature. These metric locknuts have a nylon insert that holds onto bolts without damaging their threads. They have fine-pitch threads, which are closer together than coarse-pitch threads and less likely to loosen from vibration. Fine threads and coarse threads are not compatible. These locknuts are reusable but lose holding power with each use.

Applications

Lock Nuts can be used for many different applications that include fastening wood, steel, and other construction materials for projects such as docks, bridges, highway structures, and buildings.

Black-oxide steel screws are mildly corrosion resistant in dry environments. Zinc-plated steel screws resist corrosion in wet environments. Black ultra-corrosion-resistant-coated steel screws resist chemicals and withstand 1,000 hours of salt spray.Coarse threads are the industry standard; choose these Hex nuts if you don’t know the threads per inch. Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance.

The Lock Nuts is designed to fit a ratchet or spanner torque wrenches allowing you to tighten the nuts to your exact specifications. Grade 2 bolts tend to be used in construction for joining wood components. Grade 4.8 bolts are used in small engines. Grade 8.8 10.9 or 12.9 bolts provide high tensile strength. One advantage nuts fasteners have over welds or rivets is that they allow for easy disassembly for repairs and maintenance.

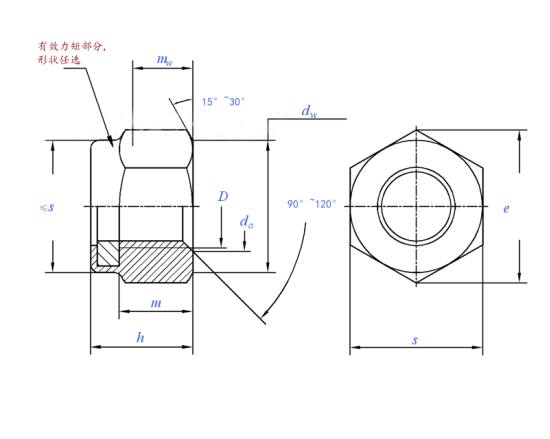

|

Thread specifications |

M5 |

M6 |

M8 |

M10 |

M12 |

(M14) |

M16 |

M20 |

M24 |

M30 |

M36 |

|

|

D |

||||||||||||

|

P |

pitch |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

3 |

3.5 |

4 |

|

da |

Maximum value |

5.75 |

6.75 |

8.75 |

10.8 |

13 |

15.1 |

17.3 |

21.6 |

25.9 |

32.4 |

38.9 |

|

minimum value |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

24 |

30 |

36 |

|

|

dw |

minimum value |

6.88 |

8.88 |

11.63 |

14.63 |

16.63 |

19.64 |

22.49 |

27.7 |

33.25 |

42.75 |

51.11 |

|

e |

minimum value |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.36 |

26.75 |

32.95 |

39.55 |

50.85 |

60.79 |

|

h |

Maximum value |

7.2 |

8.5 |

10.2 |

12.8 |

16.1 |

18.3 |

20.7 |

25.1 |

29.5 |

35.6 |

42.6 |

|

minimum value |

6.62 |

7.92 |

9.5 |

12.1 |

15.4 |

17 |

19.4 |

23 |

27.4 |

33.1 |

40.1 |

|

|

m |

minimum value |

4.8 |

5.4 |

7.14 |

8.94 |

11.57 |

13.4 |

15.7 |

19 |

22.6 |

27.3 |

33.1 |

|

mw |

minimum value |

3.84 |

4.32 |

5.71 |

7.15 |

9.26 |

10.7 |

12.6 |

15.2 |

18.1 |

21.8 |

26.5 |

|

s |

Maximum value |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

30 |

36 |

46 |

55 |

|

minimum value |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

29.16 |

35 |

45 |

53.8 |

|

|

Thousand piece weight(Steel)≈kg |

1.54 |

2.94 |

6.1 |

11.64 |

17.92 |

27.37 |

40.96 |

73.17 |

125.5 |

256.6 |

441 |

|