Produkt Yntroduksje

Metric Lock Nuts hawwe allegear in funksje dy't in net-permaninte "locking" aksje makket. Oerhearskjende Torque Lock Nuts fertrouwe op thread deformation en moatte wurde wrenched oan en út; se binne net gemysk en temperatuer beheind lykas Nylon Insert Lock Nuts mar wergebrûk is noch beheind. K-Lock Nuts binne frij draaiend en opnij te brûken. Wergebrûk fan Nylon Insert Lock Nuts is beheind en de finzene nylon ynfoegje is gefoelich foar skea troch bepaalde gemikaliën en temperatuer ekstremen; it is ek nedich om de moer oan en út te wrenchjen. Sink plated stielen moeren oant klasse 10 en RVS mei grof en fyn masine screw triedden kinne wurde levere.

Krij grip op metryske bouten bleatsteld oan trilling, wear, en feroarings yn temperatuer. Dizze metryske locknuts hawwe in nylon-ynfoegje dy't op bouten hâldt sûnder har triedden te beskeadigjen. Se hawwe fine-pitch triedden, dy't tichter byinoar binne as grof-pitch triedden en minder kâns te lossen út trilling. Fijne triedden en grouwe triedden binne net kompatibel. Dizze locknuts binne opnij te brûken, mar ferlieze hâldkrêft by elk gebrûk.

Oanfraach

Lock Nuts can be used for many different applications that include fastening wood, steel, and other construction materials for projects such as docks, bridges, highway structures, and buildings.

Black-oxide steel screws are mildly corrosion resistant in dry environments. Zinc-plated steel screws resist corrosion in wet environments. Black ultra-corrosion-resistant-coated steel screws resist chemicals and withstand 1,000 hours of salt spray.Coarse threads are the industry standard; choose these Hex nuts if you don’t know the threads per inch. Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance.

The Lock Nuts is designed to fit a ratchet or spanner torque wrenches allowing you to tighten the nuts to your exact specifications. Grade 2 bolts tend to be used in construction for joining wood components. Grade 4.8 bolts are used in small engines. Grade 8.8 10.9 or 12.9 bolts provide high tensile strength. One advantage nuts fasteners have over welds or rivets is that they allow for easy disassembly for repairs and maintenance.

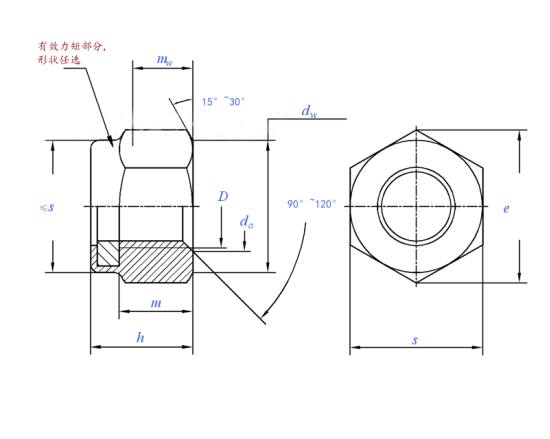

|

Thread spesifikaasjes |

M5 |

M6 |

M8 |

M10 |

M12 |

(M14) |

M16 |

M20 |

M24 |

M30 |

M36 |

|

|

D |

||||||||||||

|

P |

pitch |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

3 |

3.5 |

4 |

|

en |

Maksimum wearde |

5.75 |

6.75 |

8.75 |

10.8 |

13 |

15.1 |

17.3 |

21.6 |

25.9 |

32.4 |

38.9 |

|

minimum wearde |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

24 |

30 |

36 |

|

|

dw |

minimum wearde |

6.88 |

8.88 |

11.63 |

14.63 |

16.63 |

19.64 |

22.49 |

27.7 |

33.25 |

42.75 |

51.11 |

|

e |

minimum wearde |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.36 |

26.75 |

32.95 |

39.55 |

50.85 |

60.79 |

|

h |

Maksimum wearde |

7.2 |

8.5 |

10.2 |

12.8 |

16.1 |

18.3 |

20.7 |

25.1 |

29.5 |

35.6 |

42.6 |

|

minimum wearde |

6.62 |

7.92 |

9.5 |

12.1 |

15.4 |

17 |

19.4 |

23 |

27.4 |

33.1 |

40.1 |

|

|

m |

minimum wearde |

4.8 |

5.4 |

7.14 |

8.94 |

11.57 |

13.4 |

15.7 |

19 |

22.6 |

27.3 |

33.1 |

|

mw |

minimum wearde |

3.84 |

4.32 |

5.71 |

7.15 |

9.26 |

10.7 |

12.6 |

15.2 |

18.1 |

21.8 |

26.5 |

|

s |

Maksimum wearde |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

30 |

36 |

46 |

55 |

|

minimum wearde |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

29.16 |

35 |

45 |

53.8 |

|

|

Thousand piece weight(Steel)≈kg |

1.54 |

2.94 |

6.1 |

11.64 |

17.92 |

27.37 |

40.96 |

73.17 |

125.5 |

256.6 |

441 |

|