Product Introduction

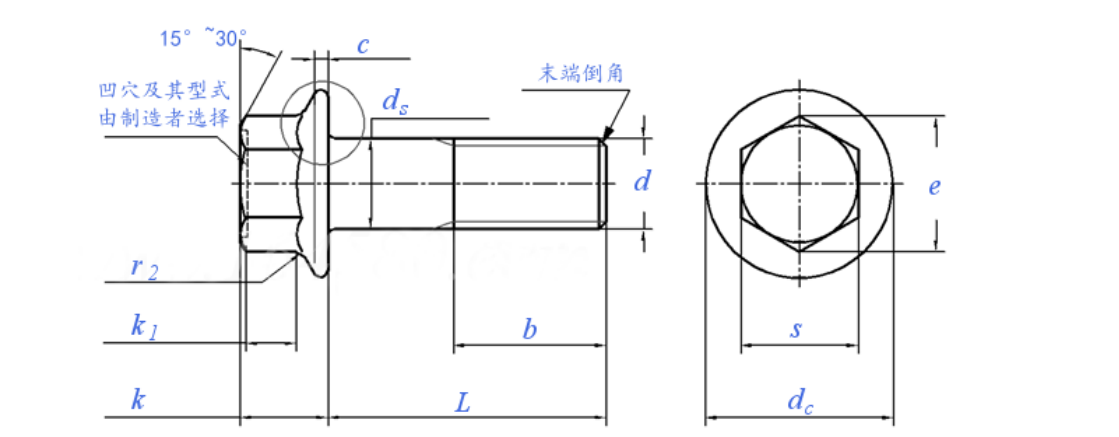

flange head bolts are used to fasten two or more parts together to form an assembly either because it cannot be manufactured as a single part or to allow for maintenance and repair disassembly.flange head bolts are mostly used in repair and construction work.

they have a flange head head and come with machine threads for a firm and rough handling. They come in a wide range of different flange head bolts sizes for custom applications depending on its dimensional requirements. These flange head bolts come in the anti-corrosion stainless steel, alloy steel and carbon steel materials which ensures that the structure doesn’t weaken because of rust. Depending on the length of the bolt, it can come with standard threading or full threading.

Applications

flange head bolts can be used for many different applications that include fastening wood, steel, and other construction materials for projects such as docks, bridges, highway structures, and buildings.flange head bolts with forged heads are also commonly used as headed anchor bolts.

Black-oxide steel screws are mildly corrosion resistant in dry environments. Zinc-plated steel screws resist corrosion in wet environments. Black ultra-corrosion-resistant-coated steel screws resist chemicals and withstand 1,000 hours of salt spray.Coarse threads are the industry standard; choose these bolts if you don’t know the threads per inch. Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance.

The bolt head is designed to fit a ratchet or spanner torque wrenches allowing you to tighten the bolt to your exact specifications.flange head bolts are typically used to create a bolted joint, in which a threaded shaft exactly fits a corresponding tapped hole or nut. Grade 2 bolts tend to be used in construction for joining wood components. Grade 4.8 bolts are used in small engines. Grade 8.8 10.9 or 12.9 bolts provide high tensile strength. One advantage bolts fasteners have over welds or rivets is that they allow for easy disassembly for repairs and maintenance.

|

Threaded specifications d |

M5 |

M6 |

M8 |

M10 |

M12 |

(M14) |

M16 |

M20 |

||

|

P |

pitch |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

|

|

b |

L≤125 |

16 |

18 |

22 |

26 |

30 |

34 |

38 |

46 |

|

|

125<L≤200 |

- |

- |

28 |

32 |

36 |

40 |

44 |

52 |

||

|

L>200 |

- |

- |

- |

- |

- |

- |

57 |

65 |

||

|

c |

least value |

1 |

1.1 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

3 |

|

|

da |

A mould |

crest value |

5.7 |

6.8 |

9.2 |

11.2 |

13.7 |

15.7 |

17.7 |

22.4 |

|

B mould |

crest value |

6.2 |

7.4 |

10 |

12.6 |

15.2 |

17.7 |

20.7 |

25.7 |

|

|

dc |

crest value |

|

11.8 |

14.2 |

18 |

22.3 |

26.6 |

30.5 |

35 |

43 |

|

ds |

crest value |

|

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

|

least value |

|

4.82 |

5.82 |

7.78 |

9.78 |

11.73 |

13.73 |

15.73 |

19.67 |

|

|

du |

crest value |

|

5.5 |

6.6 |

9 |

11 |

13.5 |

15.5 |

17.5 |

22 |

|

dw |

least value |

|

9.8 |

12.2 |

15.8 |

19.6 |

23.8 |

27.6 |

31.9 |

39.9 |

|

e |

least value |

|

8.56 |

10.8 |

14.08 |

16.32 |

19.68 |

22.58 |

25.94 |

32.66 |

|

f |

crest value |

|

1.4 |

2 |

2 |

2 |

3 |

3 |

3 |

4 |

|

k |

crest value |

|

5.4 |

6.6 |

8.1 |

9.2 |

10.4 |

12.4 |

14.1 |

17.7 |

|

k1 |

least value |

|

2 |

2.5 |

3.2 |

3.6 |

4.6 |

5.5 |

6.2 |

7.9 |

|

r1 |

least value |

|

0.25 |

0.4 |

0.4 |

0.4 |

0.6 |

0.6 |

0.6 |

0.8 |

|

r2 |

crest value |

|

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.9 |

1 |

1.2 |

|

r3 |

least value |

|

0.1 |

0.1 |

0.15 |

0.2 |

0.25 |

0.3 |

0.35 |

0.4 |

|

r4 |

consult |

|

3 |

3.4 |

4.3 |

4.3 |

6.4 |

6.4 |

6.4 |

8.5 |

|

s |

crest value |

|

8 |

10 |

13 |

15 |

18 |

21 |

24 |

30 |

|

least value |

|

7.64 |

9.64 |

12.57 |

14.57 |

17.57 |

20.16 |

23.16 |

29.16 |

|

|

t |

crest value |

|

0.15 |

0.2 |

0.25 |

0.3 |

0.35 |

0.45 |

0.5 |

0.65 |

|

least value |

|

0.05 |

0.05 |

0.1 |

0.15 |

0.15 |

0.2 |

0.25 |

0.3 |

|

|

Thousand pieces of steel weighs kg |

- |

- |

- |

- |

- |

- |

- |

- |

||

|

length of thread b |

- |

- |

- |

- |

- |

- |

- |

- |

||