wood screws

Yan . 10, 2025 09:39 Back to list

wood screws

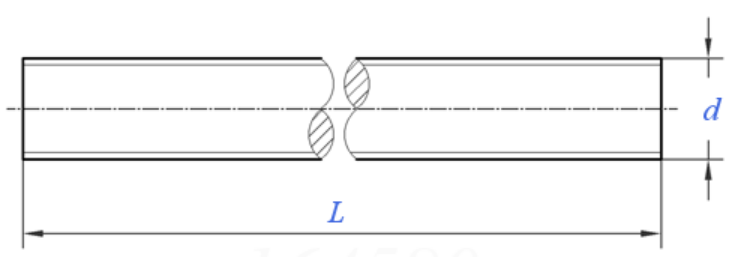

Wood screws, often hailed as the unsung heroes of woodworking, are integral components that provide structural support and precision alignment in various construction and DIY projects. These screws are designed specifically for fastening wood, providing a tight joint without the need for nuts. Their design features a sharp point that can easily penetrate timber, an ability vital for maintaining structural integrity and ensuring a long-lasting assembly.

Professionals emphasize the importance of matching screws with corresponding drivers – a reflection of best practices and authoritative expertise in woodwork. The use of a mismatched driver can compromise the screw head, leading to stripping and inefficient fastening. A Phillips screw head, for example, requires a corresponding Phillips driver, while a slot head demands a flathead driver. Ensuring compatibility not only facilitates the construction process but also enhances safety and efficiency. Trustworthiness in sourcing wood screws demands careful consideration of manufacturers and suppliers. Reputable brands ensure rigorous quality control and consistency, traits that should be prioritized to avoid structural failures. Experts recommend suppliers known for their precision engineering and adherence to industry standards. Wood screws, while appearing simple, embody a convergence of design, material science, and application expertise. Their proper utilization underscores a foundational knowledge that is critical for successful woodworking projects. By aligning the choice of screws with project requirements, woodworkers can achieve durable and aesthetically pleasing results, showcasing the screws' vital role in both functional and decorative aspects of construction.

Professionals emphasize the importance of matching screws with corresponding drivers – a reflection of best practices and authoritative expertise in woodwork. The use of a mismatched driver can compromise the screw head, leading to stripping and inefficient fastening. A Phillips screw head, for example, requires a corresponding Phillips driver, while a slot head demands a flathead driver. Ensuring compatibility not only facilitates the construction process but also enhances safety and efficiency. Trustworthiness in sourcing wood screws demands careful consideration of manufacturers and suppliers. Reputable brands ensure rigorous quality control and consistency, traits that should be prioritized to avoid structural failures. Experts recommend suppliers known for their precision engineering and adherence to industry standards. Wood screws, while appearing simple, embody a convergence of design, material science, and application expertise. Their proper utilization underscores a foundational knowledge that is critical for successful woodworking projects. By aligning the choice of screws with project requirements, woodworkers can achieve durable and aesthetically pleasing results, showcasing the screws' vital role in both functional and decorative aspects of construction.

Next:

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025