High-Quality Custom Stud Bolts for Various Industrial Applications and Needs

Dec . 05, 2024 13:03 Back to list

High-Quality Custom Stud Bolts for Various Industrial Applications and Needs

The Importance of Best Customized Stud Bolts in Modern Engineering

In the world of engineering and construction, the need for reliable and high-quality fastening solutions cannot be overstated. Among these, stud bolts have emerged as a critical component in various applications, ranging from heavy machinery to structural steel assemblies. When discussing stud bolts, it is essential to highlight the advantages of customized options tailored specifically to meet the unique demands of different industries. In this article, we will delve into the significance of best customized stud bolts, exploring their specifications, benefits, and applications in modern engineering.

Understanding Stud Bolts

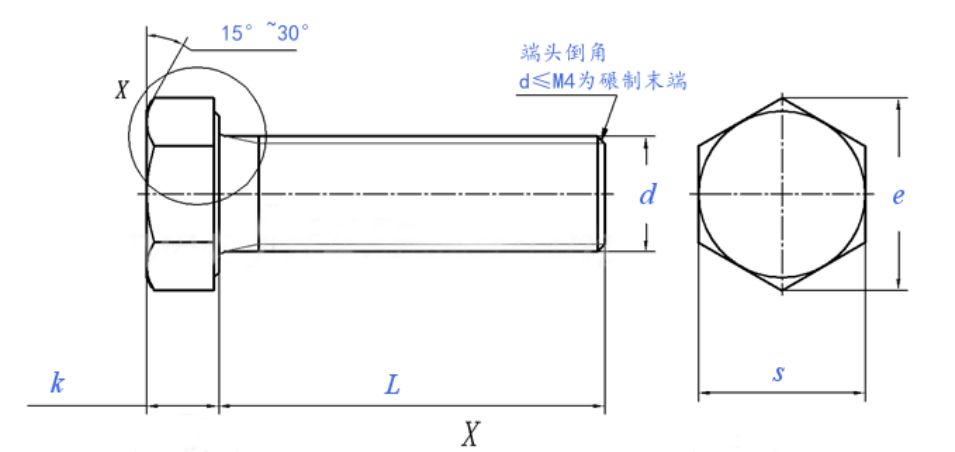

Stud bolts are elongated fasteners that feature threads on both ends, with a smooth section in the middle. They are typically used in conjunction with nuts and are essential for securing various components together. Stud bolts are commonly made from materials such as carbon steel, stainless steel, and alloy steel, providing necessary strength and corrosion resistance for different environments.

Customization Why It Matters

The concept of customization plays a vital role in ensuring that stud bolts meet specific requirements dictated by the application. Standardized bolts may not always provide the ideal solution due to differences in load specifications, environmental conditions, or design parameters. Here are a few reasons why customized stud bolts are indispensable in modern engineering

1. Precision Engineering Customized stud bolts are manufactured to exact specifications, ensuring that they fit seamlessly into the intended design. This precision is crucial for ensuring structural integrity and preventing failures that could lead to costly downtime or, worse, catastrophic accidents.

2. Material Selection Different projects require different materials based on factors such as stress, heat exposure, and potential corrosive environments. Customized stud bolts allow engineers to select the most appropriate materials that can withstand the specific conditions of the project, thereby enhancing longevity and performance.

3. Unique Thread Designs Standard thread types may not be sufficient for certain applications. Customized stud bolts can incorporate unique thread designs, ensuring better engagement with nuts and preventing slippage or loosening over time, which is especially important in critical applications such as pressure vessels and heavy machinery.

4. Variable Lengths and Diameters Projects often have varying requirements for the length and diameter of fasteners. Customized stud bolts can be produced in a wide range of sizes, catering to specific engineering needs, which helps in maintaining the correct alignment and load distribution.

Benefits of Using Customized Stud Bolts

best customized stud bolt

The advantages of utilizing customized stud bolts in engineering projects extend beyond mere compatibility. Here are a few of the key benefits

- Enhanced Safety By ensuring that the right fasteners are used for specific applications, the risk of structural failure or mechanical breakdown is significantly reduced. This is crucial in sectors like aerospace, maritime, and construction, where safety is paramount.

- Cost-Effectiveness Although customized solutions may have a higher upfront cost compared to standard options, they can ultimately be more cost-effective

. This is due to their enhanced durability and the reduced likelihood of needing replacements or repairs.- Improved Performance Customized stud bolts can be designed to optimize load-bearing capacity, vibration resistance, and overall performance. This leads to more efficient machinery operations and can improve the overall lifespan of the assemblies in which they are used.

Applications of Customized Stud Bolts

The versatility of customized stud bolts allows them to be employed across various industries. Some notable applications include

- Oil and Gas In this sector, stud bolts are critical for assembling and maintaining pipelines, pressure vessels, and offshore platforms, where high levels of stress and corrosive environments are common.

- Power Generation Customized stud bolts are used in turbines, generators, and reactors, where reliability and precision are essential to ensure efficient energy production.

- Construction In structural applications, customized stud bolts secure steel beams, columns, and pre-cast components, providing the backbone for buildings and infrastructure.

Conclusion

In summary, the significance of best customized stud bolts in modern engineering cannot be overlooked. Their critical role in ensuring safety, performance, and cost-effectiveness makes them a valuable asset across various industries. As projects continue to evolve and become more complex, the demand for tailored fastening solutions will only increase. Investing in customized stud bolts is not merely a choice but a necessity for engineers and architects who prioritize quality and reliability in their designs.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025