Leading Manufacturers of Corner Bolts for Various Industrial Applications and Needs

Dec . 05, 2024 13:14 Back to list

Leading Manufacturers of Corner Bolts for Various Industrial Applications and Needs

The Importance of Corner Bolts in Modern Manufacturing

In the realm of construction and manufacturing, fastening solutions play a crucial role in ensuring structural integrity and durability. Among these, corner bolts stand out as essential components that offer strength and reliability across various applications. Corner bolts are specifically designed to reinforce connections at right angles, making them indispensable in the assembly of frames, cabinets, and numerous industrial applications. This article explores the significance of corner bolts, the manufacturing process, and highlights some of the leading corner bolt manufacturers in the industry.

Why Corner Bolts Are Essential

Corner bolts are engineered to enhance the strength of joint connections by providing a secure anchoring point at corners where two materials meet. Their unique design allows for maximum support in right-angle configurations, which is particularly important in construction, furniture making, and metal fabrication. When used in the right context, corner bolts can significantly improve the stability of structures, preventing shifting, warping, or collapse.

In construction, corner bolts are vital for securing frames and beams, ensuring that walls and roofs maintain their intended shape and integrity. In cabinetry, corner bolts help assemble frameworks that can withstand the weight of shelves and other installations. Because of their versatility, these fasteners are commonly found in various materials, including wood, metal, and plastic, tailored to specific project requirements.

The Manufacturing Process of Corner Bolts

The production of corner bolts typically involves several steps, which include material selection, forging, machining, and finishing

. The choice of material is critical; manufacturers often utilize high-strength alloys or stainless steel to ensure durability and resistance to corrosion.1. Material Selection Quality corner bolts are made from high-performance materials suitable for the intended application. This includes consideration of factors like tensile strength and environmental resistance.

2. Forging The manufacturing process often begins with forging, where the material is heated and shaped into the desired specifications. This method enhances the grain structure of the metal, providing added strength.

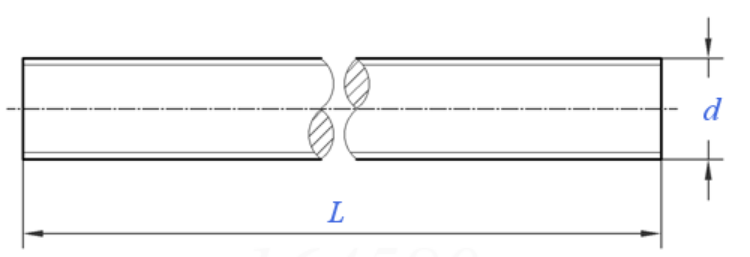

corner bolts manufacturers

3. Machining Once forged, the bolts undergo machining processes to create precision threads and to ensure that the dimensions conform to engineering standards.

4. Finishing The final stage involves finishing treatments such as galvanizing or powder coating, which not only provide an aesthetic touch but also enhance corrosion resistance.

5. Quality Control Throughout the manufacturing process, rigorous quality control measures are in place to ensure that each corner bolt meets safety standards and can withstand the stresses of use.

Leading Manufacturers of Corner Bolts

Several manufacturers have earned a reputation for producing high-quality corner bolts, catering to diverse markets globally. Companies like Fastenal, Rocky Mountain Bolt, and Bolt Products are renowned for their precision-engineered fasteners, including corner bolts. They focus on innovation and customer satisfaction, providing tailored solutions for both large-scale construction projects and small-scale applications.

Fastenal, for example, offers an extensive catalog of corner bolts in various materials and finishes, making it easy for contractors to find the right component for their needs. Similarly, Rocky Mountain Bolt emphasizes the importance of custom manufacturing, ensuring clients receive products that perfectly match their specifications.

Conclusion

Corner bolts serve as unsung heroes in construction and manufacturing, providing the necessary strength and support for countless applications. Their specialized design allows them to endure significant stress, making them indispensable in assembling structures that stand the test of time. As industries continue to evolve, the demand for high-quality corner bolts will only increase. With the commitment of leading manufacturers to innovation and quality, the future of these critical components looks promising.

For engineers, architects, and builders, understanding the importance of corner bolts and partnering with reputable manufacturers is essential for ensuring the safety and durability of their projects. Whether in furniture assembly or massive construction endeavors, corner bolts are a crucial element in creating a robust foundation for our world.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025