12 inch lag bolts companies

ഫെബ്രു . 16, 2025 16:06 Back to list

12 inch lag bolts companies

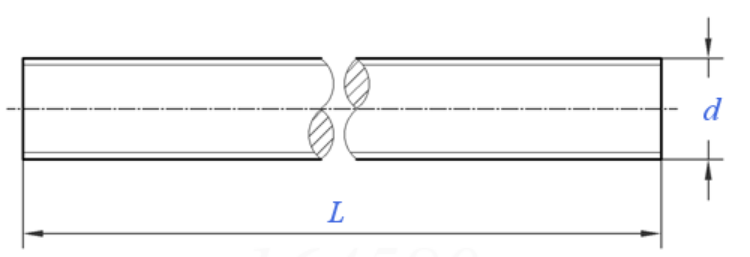

Shear off bolts, often used in engineering and construction, serve the critical function of facilitating mechanical safety and structural integrity. The use of shear off bolts is prevalent across various industries, owing to their unique ability to prevent overloading by shearing at a predetermined force. This article delves into the intricacies of shear off bolts, aiming to provide a comprehensive understanding of their application and benefits for industry professionals.

In selecting shear off bolts for specific applications, considerations must include the anticipated load, environmental conditions, and the mechanical requirements of the connected components. Industry experts recommend a detailed analysis to determine the appropriate bolt size, material, and shear point. This analysis should also consider environmental factors such as temperature variations and potential exposure to corrosive elements, each of which can affect the bolt's longevity and performance. From an expert standpoint, the advantages of utilizing shear off bolts extend beyond just mechanical safety; they also contribute to cost efficiency and operational reliability. By preventing major structural failures, they reduce the frequency and costs associated with emergency repairs and downtime. Engineers thereby gain a reliable partner in shear off bolts, knowing that the risk of overloading can be managed effectively without compromising structural integrity. The application of shear off bolts requires a strong understanding of engineering principles and material science. Professionals tasked with their implementation should possess the expertise to conduct precise calculations and assessments needed to determine the appropriate specifications for each unique use case. Continuous training and adherence to current industry trends are equally vital to maintain cutting-edge expertise in this field. Moreover, ongoing research in materials science and engineering design is constantly improving the capabilities of shear off bolts. Innovations in composite materials and smart technology integration, such as sensors that detect approaching shear limits, are poised to bolster their safety and efficiency further. Manufacturers remain at the forefront of adopting these advancements, ensuring that shear off bolts continue to meet the evolving demands of modern engineering challenges. In conclusion, shear off bolts are indispensable in safeguarding structural integrity and enhancing operational reliability across a multitude of industries. Through a combination of robust materials, precise engineering, and adherence to international standards, they provide a fail-safe mechanism essential for managing mechanical stress effectively. For professionals managing complex engineering projects, understanding the nuances of shear off bolts is crucial to leveraging their full potential in enhancing safety and efficiency.

In selecting shear off bolts for specific applications, considerations must include the anticipated load, environmental conditions, and the mechanical requirements of the connected components. Industry experts recommend a detailed analysis to determine the appropriate bolt size, material, and shear point. This analysis should also consider environmental factors such as temperature variations and potential exposure to corrosive elements, each of which can affect the bolt's longevity and performance. From an expert standpoint, the advantages of utilizing shear off bolts extend beyond just mechanical safety; they also contribute to cost efficiency and operational reliability. By preventing major structural failures, they reduce the frequency and costs associated with emergency repairs and downtime. Engineers thereby gain a reliable partner in shear off bolts, knowing that the risk of overloading can be managed effectively without compromising structural integrity. The application of shear off bolts requires a strong understanding of engineering principles and material science. Professionals tasked with their implementation should possess the expertise to conduct precise calculations and assessments needed to determine the appropriate specifications for each unique use case. Continuous training and adherence to current industry trends are equally vital to maintain cutting-edge expertise in this field. Moreover, ongoing research in materials science and engineering design is constantly improving the capabilities of shear off bolts. Innovations in composite materials and smart technology integration, such as sensors that detect approaching shear limits, are poised to bolster their safety and efficiency further. Manufacturers remain at the forefront of adopting these advancements, ensuring that shear off bolts continue to meet the evolving demands of modern engineering challenges. In conclusion, shear off bolts are indispensable in safeguarding structural integrity and enhancing operational reliability across a multitude of industries. Through a combination of robust materials, precise engineering, and adherence to international standards, they provide a fail-safe mechanism essential for managing mechanical stress effectively. For professionals managing complex engineering projects, understanding the nuances of shear off bolts is crucial to leveraging their full potential in enhancing safety and efficiency.

Latest news

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025