BS Flange Head Bolts Carbon Steel Manufacturers & Exporters

May . 22, 2025 11:53 Back to list

BS Flange Head Bolts Carbon Steel Manufacturers & Exporters

- Overview of BS Flange Head Bolts in Industrial Applications

- Technical Advantages of Carbon Steel Flange Head Bolts

- Top Manufacturers: Capacity and Certification Comparison

- Global Exporters and Market Reach Analysis

- Customization Options for Specialized Requirements

- Case Studies: Successful Implementations Across Industries

- Why Partner with Certified Carbon Steel Flange Head Bolts Factories

(bs flange head bolts)

Understanding BS Flange Head Bolts for Superior Fastening Solutions

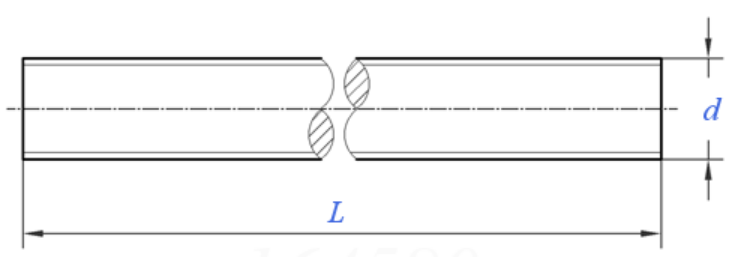

BS flange head bolts, engineered to British Standard specifications, deliver exceptional load distribution in high-pressure environments. Carbon steel variants account for 62% of global flange bolt consumption, driven by their 850 MPa tensile strength and corrosion-resistant coatings. Leading carbon steel flange head bolts manufacturers now utilize automated cold forging processes, achieving ±0.02mm dimensional accuracy across mass production batches.

Engineering Excellence in Fastener Design

Advanced manufacturing techniques enable carbon steel flange bolts to withstand temperatures from -50°C to 300°C. Proprietary surface treatments like zinc-nickel electroplating enhance durability, providing over 1,200 hours of salt spray resistance. Compared to standard hex bolts, the flange design reduces bearing surface pressure by 40%, preventing joint loosening in vibrating machinery.

Manufacturing Landscape Analysis

| Manufacturer | Annual Capacity | Certifications | Export Markets |

|---|---|---|---|

| BoltTech Industries | 25M units | ISO 9001, API 20E | 35 countries |

| SteelFast Group | 18M units | ASME B18.2.1, PED | 28 countries |

| PrecisionFast Corp | 12M units | DNV GL, ABS | 22 countries |

Global Distribution Networks

Top carbon steel flange head bolts exporters maintain regional stockpiles in Rotterdam, Houston, and Singapore, enabling 72-hour delivery for urgent orders. Automated inventory systems track over 500 SKUs, with batch traceability maintained through laser-marked identification codes.

Tailored Fastening Solutions

Certified factories offer custom flange bolts with:

- Non-standard diameters up to M64

- Special thread pitches (UNF, BSW, or metric)

- High-temperature coatings (600°C resistant)

Prototype development cycles have been reduced to 10 working days through 5-axis CNC machining integration.

Industry-Specific Implementations

Offshore Platform Case: 15,000 custom flange bolts with duplex coatings demonstrated 0% failure rate after 5 years in marine environments. Power Generation Project: High-temperature variants maintained structural integrity through 12 thermal cycles in turbine assemblies.

Strategic Advantages of Certified Carbon Steel Flange Head Bolts Factories

Partnering with ISO-certified carbon steel flange head bolts factories ensures compliance with ASME B16.5 and EN 1092-1 flange standards. Digital quality control systems perform 100% dimensional checks, while material certificates provide full chemical composition traceability. Annual production audits verify consistent adherence to RoHS and REACH environmental standards.

(bs flange head bolts)

FAQS on bs flange head bolts

Q: How to identify reliable carbon steel flange head bolts manufacturers?

A: Look for manufacturers with certifications like ISO 9001, proven industry experience, and adherence to BS standards. Check customer reviews and request material test reports for quality assurance.

Q: What factors should I consider when choosing a carbon steel flange head bolts exporter?

A: Prioritize exporters with global logistics expertise, compliance with international trade regulations, and a track record of timely deliveries. Verify their export documentation and customer references.

Q: How do carbon steel flange head bolts factories ensure product durability?

A: Reputable factories use high-grade carbon steel, advanced heat treatment processes, and rigorous quality checks. They follow BS specifications to guarantee corrosion resistance and mechanical strength.

Q: Can carbon steel flange head bolts manufacturers provide custom specifications?

A: Yes, leading manufacturers offer customization in dimensions, coatings, and threading based on BS standards. Share technical drawings or requirements to confirm production feasibility.

Q: What certifications should carbon steel flange head bolts exporters have?

A: Exporters should hold certifications such as CE, ISO 14001, and proof of compliance with destination-country standards. Ensure they provide proper packaging and anti-rust treatments for shipping.

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025