flat washer

មករា . 10, 2025 08:33 Back to list

flat washer

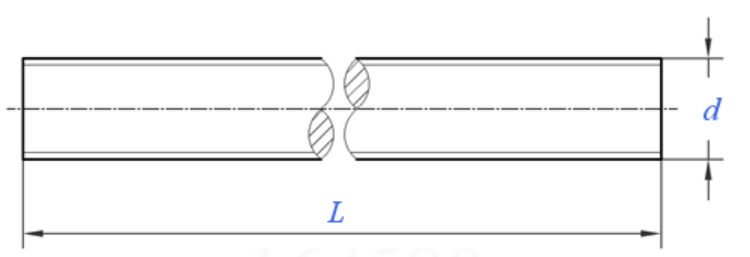

Flat washers are an essential yet often overlooked component in bolted assemblies within various industries, ranging from automotive to aerospace. These small, disk-shaped plates with a central hole are designed to distribute the load of a threaded fastener, such as a screw or nut, over a broader surface area, mitigating potential damage or loosening under pressure. Their simplicity belies the critical role they play in ensuring the stability and longevity of mechanical assemblies.

Authoritativeness in the field of flat washers emanates from research and adherence to industry standards. Manufacturers and suppliers who engage in rigorous testing and quality assurance procedures produce washers that meet or exceed standards set by organizations like ISO or SAE. By choosing washers from superior sources, professionals increase the reliability and safety of their assemblies, reinforcing the authority of their work in structural integrity. Trustworthiness, a crucial factor, hinges on consistent performance and transparency. When a product like a flat washer is claimed to be reliable, it should deliver that promise without exception. Reputable suppliers not only offer documentation that detail material compositions and performance tests but also stand behind their products with warranties or certifications. This approach empowers engineers and end-users to trust the components in their systems, ensuring peace of mind and sustained functionality. In conclusion, flat washers, though simple, are indispensable to the stability of many structural applications. Their efficacy in load distribution, protection of substrates, and prevention of loosening is unparalleled when selected with precision. Malfunction due to inappropriate washer choice is a risk that underscores the value of expertise, authority, and trust in the field. As industries continue to innovate, the foundational role of flat washers remains steadfast, underpinning the intricate tapestry of design and engineering excellence.

Authoritativeness in the field of flat washers emanates from research and adherence to industry standards. Manufacturers and suppliers who engage in rigorous testing and quality assurance procedures produce washers that meet or exceed standards set by organizations like ISO or SAE. By choosing washers from superior sources, professionals increase the reliability and safety of their assemblies, reinforcing the authority of their work in structural integrity. Trustworthiness, a crucial factor, hinges on consistent performance and transparency. When a product like a flat washer is claimed to be reliable, it should deliver that promise without exception. Reputable suppliers not only offer documentation that detail material compositions and performance tests but also stand behind their products with warranties or certifications. This approach empowers engineers and end-users to trust the components in their systems, ensuring peace of mind and sustained functionality. In conclusion, flat washers, though simple, are indispensable to the stability of many structural applications. Their efficacy in load distribution, protection of substrates, and prevention of loosening is unparalleled when selected with precision. Malfunction due to inappropriate washer choice is a risk that underscores the value of expertise, authority, and trust in the field. As industries continue to innovate, the foundational role of flat washers remains steadfast, underpinning the intricate tapestry of design and engineering excellence.

Next:

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025