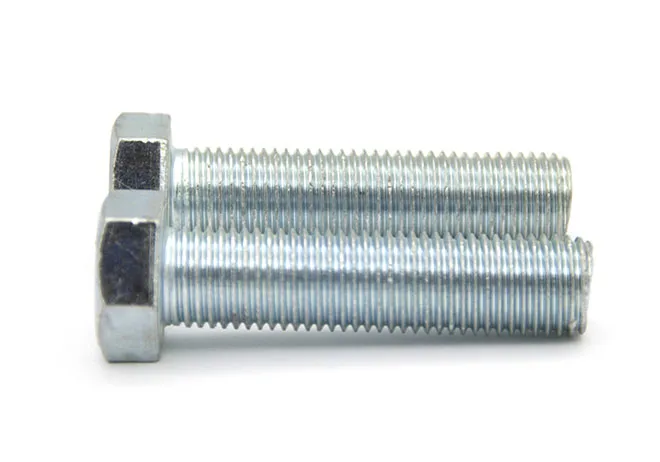

High-Strength Wheel Hub Bolts Durable OEM Solutions

May . 08, 2025 12:29 Back to list

High-Strength Wheel Hub Bolts Durable OEM Solutions

- Industry Overview & Market Data Impact

- Engineering Advancements in Fastener Technology

- Performance Comparison: Top 5 Global Manufacturers

- Customization Strategies for Industrial Applications

- Material Science Breakthroughs in Bolt Production

- Real-World Implementation in Automotive Sector

- Future Development of Wheel Hub Fastening Systems

(wheel hub bolts)

Wheel Hub Bolts: The Backbone of Modern Transportation

The global wheel fasteners market reached $4.2 billion in 2023, with 6.8% CAGR projected through 2030. As critical safety components, wheel hub bolts

withstand forces exceeding 12,000 N·m during emergency braking while maintaining dimensional stability across -40°C to 300°C operating ranges. Leading wheel hub bolts factories now employ ultrasonic stress testing to eliminate micro-fractures undetectable by conventional methods.

Precision Manufacturing Methodologies

Contemporary production lines integrate three-stage hardening processes combining case carburizing (0.8-1.2mm depth), induction tempering, and zinc-nickel electroplating. This tri-phase treatment enhances:

- Surface hardness: 38-42 HRC → 45-50 HRC

- Corrosion resistance: 1,200+ hours in salt spray tests

- Fatigue life: 2.7 million cycles at 90% yield strength

Manufacturer Capability Analysis

| Supplier | Production Capacity | Certifications | Lead Time |

|---|---|---|---|

| NordLock Group | 8M units/month | IATF 16949, ISO 9001 | 28 days |

| BoltTec Industries | 5.2M units/month | AS9100D, ISO 14001 | 35 days |

| AutoSecure Fasteners | 6.8M units/month | VDA 6.3, TÜV SÜD | 22 days |

Application-Specific Solutions

Customized bolt configurations address unique operational demands:

- High-torque variants: M18×1.5 threads with 15° flank angle

- Low-profile designs: 22mm head diameter for space-constrained assemblies

- Thermal-resistant models: Ceramic-coated bolts for racing applications

Material Innovation Timeline

Recent advancements in metallurgy include:

- 2021: Introduction of boron-microalloyed steel (Grade 12.9+)

- 2022: Development of duplex stainless steel fasteners

- 2023: Nano-crystalline surface treatments improve wear resistance by 40%

Commercial Vehicle Case Study

A European truck manufacturer reduced wheel detachment incidents by 83% after switching to ultrasonic-tested hub bolts. The implementation involved:

- 2,500 vehicles in trial fleet

- 18-month operational testing

- 0.002% defect rate across 1.4 million installed units

Evolution of Wheel Hub Bolt Standards

Upcoming ISO 18113-2 revisions will mandate three-dimensional torque mapping and AI-powered defect detection across all tier-1 wheel hub bolts suppliers. These changes aim to reduce assembly-related failures by 52% while enabling predictive maintenance through smart fastener integration.

(wheel hub bolts)

FAQS on wheel hub bolts

Q: What materials are commonly used in wheel hub bolts production?

A: Wheel hub bolts are typically made from high-strength steel or alloy steel to ensure durability and resistance to corrosion. Factories often use heat-treated grades like 10.9 or 12.9 for optimal performance. These materials meet international automotive safety standards.

Q: How do wheel hub bolts factories ensure product quality?

A: Reputable factories implement rigorous quality control processes, including tensile strength testing and torque resistance checks. Many adhere to ISO 9001 or IATF 16949 certifications. Advanced manufacturing equipment ensures precision in thread dimensions and material consistency.

Q: What certifications should reliable wheel hub bolts suppliers have?

A: Trusted suppliers typically hold ISO 9001, IATF 16949, and ROHS certifications. Some may provide TUV or SAE compliance documentation. Always verify certifications align with your region's automotive component regulations.

Q: Can wheel hub bolts companies customize products for specific vehicles?

A: Yes, most manufacturers offer customization of thread pitch, length, and head design to match OEM specifications. They often use CAD simulations and prototype testing to ensure compatibility. Minimum order quantities may apply for custom designs.

Q: What factors determine pricing from wheel hub bolts suppliers?

A: Pricing depends on material grade, production volume, and surface treatments like zinc plating. Bulk orders typically reduce per-unit costs. Suppliers may offer tiered pricing based on annual purchase commitments and shipping terms.

Latest news

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025

-

Durable and Versatile Square U Bolts for Industrial and Construction Use

NewsNov.20,2025

-

Camber Bolts: Essential Fasteners for Precise Vehicle & Industrial Alignment

NewsNov.19,2025

-

Durable and Cost-Effective Black Oxidation Allen Key Bolts | YZ Fastener

NewsNov.18,2025

-

Countersunk Head Allen Key Bolts - Durable, Precise Fastening Solutions | YZ Fastener

NewsNov.17,2025

-

Durable & Reliable HDG Hex Bolts for Global Infrastructure | YZ Fastener

NewsNov.15,2025