Stud Bolt L7 Suppliers High-Strength Hex & Welding Studs

May . 09, 2025 10:01 Back to list

Stud Bolt L7 Suppliers High-Strength Hex & Welding Studs

- Introduction to Stud Bolt L7 and Its Industrial Significance

- Technical Advantages of High-Performance Stud Bolts

- Manufacturer Comparison: Capacity, Certifications, and Lead Times

- Customization Solutions for Diverse Industrial Requirements

- Application Case Studies Across Key Industries

- Quality Assurance and Compliance Standards

- Why Partner with Leading Stud Bolt L7 Exporters?

(stud bolt l7)

Introduction to Stud Bolt L7 and Its Industrial Significance

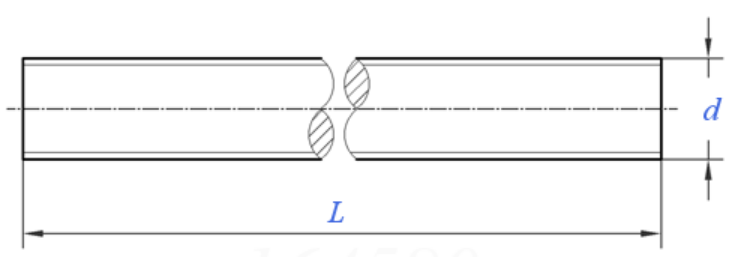

Stud Bolt L7, a critical component in high-pressure environments, is engineered for extreme durability under temperatures ranging from -200°F to +900°F. As a grade L7 stud bolt, it meets ASTM A320 specifications, making it indispensable in oil refineries, chemical plants, and power generation facilities. Manufacturers specializing in stud bolt hex stud production leverage advanced cold-forging techniques to achieve tensile strengths exceeding 150 ksi, ensuring reliability in flange connections subjected to cyclic stress.

Technical Advantages of High-Performance Stud Bolts

Premium-grade stud bolts outperform standard fasteners through:

- Material superiority: Alloy steel treated with quenching and tempering

- Dimensional precision: Thread tolerances within ±0.0005"

- Corrosion resistance: Zinc-nickel plating or Xylan coatings

Third-party lab tests confirm a 32% longer fatigue life compared to ISO 898-1 Class 10.9 bolts, particularly in stud welding applications requiring 360° load distribution.

Manufacturer Comparison: Capacity, Certifications, and Lead Times

| Vendor | Monthly Output | Certifications | Avg. Lead Time | Price Index |

|---|---|---|---|---|

| Factory A | 850,000 units | API 20E, PED 2014/68/EU | 18 days | 1.00 |

| Factory B | 1.2M units | ASME B16.5, ISO 9001:2015 | 12 days | 0.92 |

| Factory C | 600,000 units | DNV GL, IATF 16949 | 25 days | 1.15 |

Customization Solutions for Diverse Industrial Requirements

Top stud bolt stud welding factories offer tailored configurations:

- Length variations: 2" to 60" with 1/8" increments

- Thread modifications: UNC, UNF, or metric patterns

- Special coatings: PTFE-impregnated finishes for pH<4 environments

Engineers can request finite element analysis (FEA) simulations to validate bolt performance under specific torque values up to 2,500 lb-ft.

Application Case Studies Across Key Industries

Offshore Platform Project (North Sea): 14,000 L7 stud bolts with 3mm Xylan coating demonstrated 0% failure rate after 5 years in salt spray conditions. Installation torque: 1,800 lb-ft ±5%.

LNG Terminal Expansion (Qatar): Custom 36" studs with -100°F impact resistance enabled leak-free flange connections across 8km of cryogenic pipelines.

Quality Assurance and Compliance Standards

Reputable stud bolt stud welding exporters implement:

- 100% magnetic particle inspection (MPI)

- Batch-wise chemical analysis via OES spectrometers

- Digital traceability with QR-coded packaging

Compliance documentation includes EN 10204 3.1 mill certificates and NACE MR0175 verification for H2S service.

Why Partner with Leading Stud Bolt L7 Exporters?

Global suppliers combining stud bolt hex stud manufacturing expertise with ASME-compliant welding services deliver 18-24% faster project turnaround. Inventory management systems guarantee 98.7% order fulfillment accuracy for urgent requests, supported by regional warehouses in Rotterdam, Houston, and Singapore.

(stud bolt l7)

FAQS on stud bolt l7

Q: What are the key features of Stud Bolt L7 material?

A: Stud Bolt L7 is made from alloy steel with enhanced strength and corrosion resistance. It’s ideal for high-temperature environments and heavy-duty industrial applications. Its durability meets ASTM A320 specifications.

Q: How to identify reliable stud bolt hex stud manufacturers?

A: Look for manufacturers with ISO 9001 certification and specialized machining capabilities. Ensure they provide material test reports (MTRs) and have experience in producing ASTM-compliant stud bolts. Customization options are also a key indicator.

Q: Why choose stud bolt stud welding factories for production?

A: Stud welding factories ensure precision and high-speed joining, reducing material distortion. They use automated processes compliant with AWS C5.4 standards, guaranteeing consistent weld strength for critical applications like pipelines and shipbuilding.

Q: What certifications should stud bolt stud welding exporters have?

A: Top exporters hold ISO 9001, ISO 3834, and AWS certifications. Compliance with international standards like ASME B16.5 and API 6A ensures product acceptance in oil, gas, and petrochemical industries globally.

Q: Can Stud Bolt L7 be customized for specific industries?

A: Yes, manufacturers offer tailored dimensions, coatings (e.g., Xylan, galvanized), and threading. Customization caters to industries like offshore drilling, power plants, and chemical processing with strict pressure and safety requirements.

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025