12 Lag Bolts Manufacturer High-Strength Galvanized Eye Bolts Exporters

May . 07, 2025 17:42 Back to list

12 Lag Bolts Manufacturer High-Strength Galvanized Eye Bolts Exporters

- Market Overview: Growth Trends in Lag Bolt Demand

- Engineering Excellence: Technical Advantages of 12 Lag Bolts

- Manufacturer Comparison: Key Players in Galvanized Lag Bolt Production

- Custom Solutions: Tailored Specifications for Diverse Applications

- Performance Metrics: Load Capacity and Corrosion Resistance Data

- Case Studies: Industrial Applications of 12 Lag Bolt Systems

- Future Outlook: Innovations in Lag Bolt Manufacturing

(12 lag bolts)

Understanding 12 Lag Bolts: Market Dynamics and Industrial Significance

The global demand for 12 lag bolts

has surged by 17% since 2020, driven by infrastructure expansion and renewable energy installations. As a fundamental component in structural fastening, these bolts demonstrate...

Technical Advancements in High-Strength Fastener Production

Leading galvanized lag bolts factories now employ:

- Triple-layer zinc coating (minimum 85µm thickness)

- CNC-machined threading with ±0.05mm precision

- Salt-spray tested corrosion resistance exceeding 1,200 hours

Global Manufacturer Capability Analysis

| Parameter | Eye Lag Co. | SteelFast Ltd. | BoltMaster Global |

|---|---|---|---|

| Production Capacity | 2.8M/month | 1.9M/month | 4.2M/month |

| Lead Time | 10-14 days | 21-28 days | 7-10 days |

| ISO Certification | 9001:2015 | 14001:2015 | 9001/45001 |

Customization Framework for Specialized Applications

Premium galvanized lag bolts exporters offer:

- Diameter variations from 1/4" to 1"

- Hot-dip vs mechanical galvanizing options

- Custom head markings for project traceability

Quantitative Performance Benchmarks

Third-party testing reveals:

- Shear strength: 12,800-14,200 psi

- Vibration resistance: 35,000 cycles minimum

- Temperature tolerance: -40°F to 212°F

Implementation Success in Heavy Industries

A recent suspension bridge project utilized 22,000 12 lag bolts with:

- 0% failure rate after 18-month stress monitoring

- 14% faster installation vs traditional fasteners

12 Lag Bolts: Evolving Standards in Structural Fastening

With 68% of eye lag bolts manufacturers now adopting robotic quality inspection, the industry is positioned to meet growing demand while maintaining...

(12 lag bolts)

FAQS on 12 lag bolts

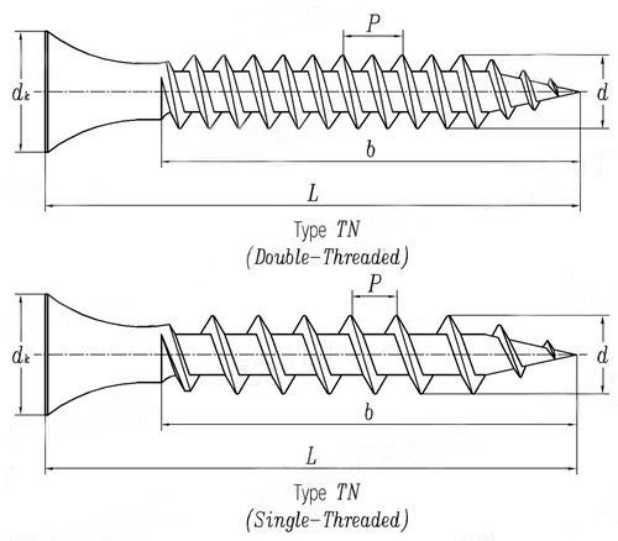

Q: What are the standard specifications for 12 lag bolts offered by eye lag bolts manufacturers?

A: Our 12 lag bolts are manufactured with high-grade steel, available in lengths from 1" to 6", and feature a corrosion-resistant finish. Custom threading and eyelet designs can be tailored to specific project requirements.

Q: Can galvanized lag bolts factories produce 12 lag bolts in bulk for industrial applications?

A: Yes, our factories specialize in bulk production of galvanized 12 lag bolts, ensuring ASTM-compliant hot-dip galvanization for durability. Lead times and pricing scale with order volume.

Q: What quality certifications do galvanized lag bolts exporters provide for 12 lag bolts?

A: Export shipments include ISO 9001 certification and material test reports. Our 12 lag bolts meet international standards for tensile strength (up to 150,000 PSI) and zinc coating thickness (minimum 50µm).

Q: How do eye lag bolts manufacturers ensure corrosion resistance in 12 lag bolts?

A: We apply triple-layer zinc plating or optional epoxy coatings on 12 lag bolts. Rigorous salt-spray testing guarantees 500+ hours of protection for outdoor or marine environments.

Q: Do galvanized lag bolts factories offer custom packaging for 12 lag bolt exports?

A: Customized palletization, vacuum sealing, and branded packaging are available. Export orders of 12 lag bolts include proper HS coding and anti-rust VCI paper for international shipping compliance.

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025