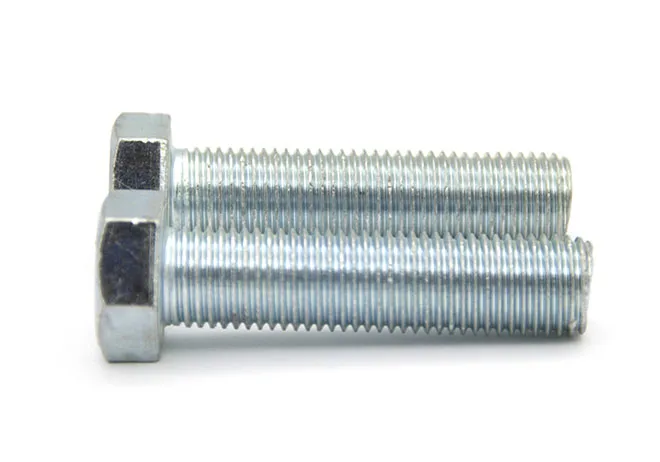

FLANGE HEAD BOLTS

Feb . 18, 2025 01:55 Back to list

FLANGE HEAD BOLTS

When it comes to securing components in a diverse range of applications, B8 bolts are a go-to solution, known for their high-strength and reliability under demanding conditions. These bolts, made from alloy steel, play an integral role in industries such as petrochemicals, construction, and manufacturing machinery where durability and resistance to harsh environments are paramount.

Furthermore, when considering the trustworthiness of hardware components, B8 bolts stand out due to their proven track record. They have been tested and certified to withstand high-pressure environments, an assurance that underscores their safety and effectiveness. Manufacturers who prioritize reliability will often choose B8 bolts over lesser alternatives, understanding that failure is not an option in critical applications. From a professional standpoint, expertise plays a critical role in selecting the right type of B8 bolt for a specific application. It is crucial to consider the grade and specifications based on the intended use, load requirements, and environmental conditions. Consulting with a skilled engineer or sourcing from reputable suppliers can ensure the optimal choice is made, thereby maximizing the performance and safety of the application. Lastly, the price-to-performance ratio of B8 bolts is another aspect that enhances their desirability. While they might come with a higher upfront cost compared to standard bolts, the longevity and reduced need for replacements make them a cost-effective choice in the long term. This aspect of financial sensibility has been echoed by procurement experts who argue for their inclusion in various budget-conscious projects. In conclusion, B8 bolts represent a fusion of strength, reliability, and expert engineering. Their capability to withstand severe conditions while maintaining structural integrity makes them indispensable in various industries. Leveraging the expertise and experience of seasoned professionals and prioritizing authoritative, high-quality products ensures that projects benefit from components that are both trustworthy and effective. As industries continue to evolve with increasing demands for safety and performance, B8 bolts remain a steadfast solution for secure, durable, and reliable fastening.

Furthermore, when considering the trustworthiness of hardware components, B8 bolts stand out due to their proven track record. They have been tested and certified to withstand high-pressure environments, an assurance that underscores their safety and effectiveness. Manufacturers who prioritize reliability will often choose B8 bolts over lesser alternatives, understanding that failure is not an option in critical applications. From a professional standpoint, expertise plays a critical role in selecting the right type of B8 bolt for a specific application. It is crucial to consider the grade and specifications based on the intended use, load requirements, and environmental conditions. Consulting with a skilled engineer or sourcing from reputable suppliers can ensure the optimal choice is made, thereby maximizing the performance and safety of the application. Lastly, the price-to-performance ratio of B8 bolts is another aspect that enhances their desirability. While they might come with a higher upfront cost compared to standard bolts, the longevity and reduced need for replacements make them a cost-effective choice in the long term. This aspect of financial sensibility has been echoed by procurement experts who argue for their inclusion in various budget-conscious projects. In conclusion, B8 bolts represent a fusion of strength, reliability, and expert engineering. Their capability to withstand severe conditions while maintaining structural integrity makes them indispensable in various industries. Leveraging the expertise and experience of seasoned professionals and prioritizing authoritative, high-quality products ensures that projects benefit from components that are both trustworthy and effective. As industries continue to evolve with increasing demands for safety and performance, B8 bolts remain a steadfast solution for secure, durable, and reliable fastening.

Next:

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025