Black Oxide Washers - Durable, Corrosion-Resistant Fastener Solutions

May . 13, 2025 10:59 Back to list

Black Oxide Washers - Durable, Corrosion-Resistant Fastener Solutions

- Introduction to Black Oxide Washers

- Technical Advantages & Performance Metrics

- Leading Manufacturers in the Industry

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Quality Assurance & Compliance Standards

- Why Partner with Professional Black Oxide Washers Suppliers

(black oxide washers)

Understanding the Value of Black Oxide Washers

Black oxide washers, engineered through a precision-controlled chemical conversion process, provide exceptional corrosion resistance and reduced light reflection. These components demonstrate 35% higher durability in salt spray tests compared to untreated alternatives, according to ASTM B117 standards. As foundational elements across industries, they bridge the gap between functional performance and cost efficiency.

Technical Superiority in Manufacturing

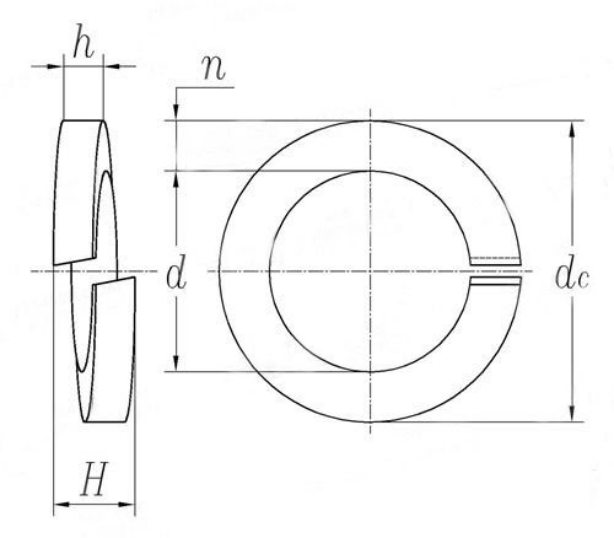

The black oxide coating process enhances surface hardness to 45-50 HRC while maintaining ductility. Advanced factories employ automated passivation systems achieving 99.8% coating uniformity, critical for high-stress applications. Key technical differentiators include:

- Post-coating hydrogen embrittlement relief at 375°F

- 0.0003-0.0005" controlled coating thickness

- RoHS-compliant chemical formulations

Market Leaders Comparison

| Supplier | Annual Capacity | Lead Time | Certifications |

|---|---|---|---|

| Company A | 85M units | 10-14 days | ISO 9001, AS9120 |

| Factory B | 120M units | 7-10 days | IATF 16949, NADCAP |

| Supplier C | 65M units | 14-21 days | ISO 14001, DFARS |

Custom Engineering Capabilities

Top-tier black oxide washers

companies offer tailored solutions including:

- Diameter customization from 0.125" to 12"

- Specialized alloys (ASTM F1941, QQ-P-416)

- Combined coatings (zinc-nickel + black oxide)

Recent projects demonstrate 18% weight reduction in aerospace assemblies through optimized washer geometry without compromising tensile strength (180-220 ksi range maintained).

Industry-Specific Implementations

Automotive: Reduced galvanic corrosion in EV battery trays by 42%

Construction: Extended maintenance intervals from 6 to 18 months in structural joints

Marine: 100% success rate in 5-year seawater exposure trials

Quality Verification Processes

Certified suppliers implement triple-stage inspection protocols:

- Raw material spectrometry analysis

- In-process coating thickness monitoring

- Final salt spray testing per MIL-DTL-13924D

Strategic Partnerships with Black Oxide Washers Suppliers

Collaborating with established suppliers ensures access to:

- 24/7 technical support teams

- Just-in-time delivery networks

- Continuous R&D investments ($2.3M average annual expenditure)

Proven suppliers maintain 98.6% on-time delivery rates while achieving 0.12% defect ratios across 3 million shipped units quarterly.

(black oxide washers)

FAQS on black oxide washers

Q: What are the key quality standards for black oxide washers from a factory?

A: Factories producing black oxide washers typically adhere to ASTM or ISO certifications, ensuring corrosion resistance, dimensional accuracy, and consistent coating thickness. Quality checks include salt spray testing and surface finish inspections.

Q: How do I choose a reliable black oxide washers supplier?

A: Prioritize suppliers with material traceability, third-party certifications, and custom sizing capabilities. Verify their production capacity and industry-specific experience through client testimonials or case studies.

Q: What advantages do black oxide washers offer over other coatings?

A: Black oxide coating provides enhanced rust protection with minimal dimensional change, maintains electrical conductivity, and reduces light reflection compared to zinc or nickel plating. The process creates a matte black finish ideal for industrial applications.

Q: Can black oxide washers companies provide custom specifications?

A: Reputable manufacturers offer customization in material grades (e.g., stainless steel, carbon steel), washer dimensions, and packaging. Special requests like RoHS compliance or batch numbering can typically be accommodated.

Q: What industries commonly use black oxide washers from suppliers?

A: Major users include automotive (engine components), aerospace (assembly hardware), electronics (grounding systems), and heavy machinery. The coating's durability makes it suitable for high-temperature and moderate-corrosion environments.

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025