Carbon Steel Stud Bolt Manufacturing Companies and Their Key Features

نومبر . 16, 2024 13:15 Back to list

Carbon Steel Stud Bolt Manufacturing Companies and Their Key Features

Carbon Steel Stud Bolt Factories An Overview

In the industrial landscape, the significance of fasteners such as stud bolts cannot be overstated. These components serve as critical connectors in various applications, particularly in construction, manufacturing, and engineering sectors. Among the diverse materials used to produce stud bolts, carbon steel stands out due to its strength, durability, and cost-effectiveness. This article delves into the world of carbon steel stud bolt factories, examining their production processes, advantages, and their role in various industries.

The Production Process

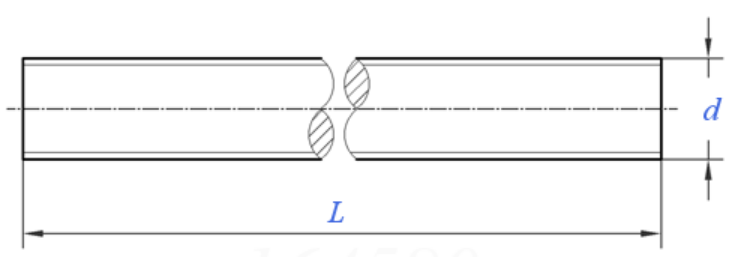

Carbon steel stud bolt factories employ a systematic approach to manufacturing. The production process begins with the selection of high-quality carbon steel, which typically contains up to 2% carbon. This material is favored for its toughness and ability to withstand high loads, making it ideal for heavy-duty applications.

Once the raw materials are selected, the manufacturing process commences with forging or machining. In forging, the carbon steel is heated and shaped into the desired form through the application of force. This method enhances the mechanical properties of the material, producing stronger fasteners. Alternatively, some factories opt for machining, where the steel is cut into shape using precision tools. Regardless of the method used, strict quality control measures are implemented throughout the production process to ensure that the stud bolts meet industry standards.

After shaping the bolts, they undergo a heat treatment process to enhance their mechanical properties further. Through processes like quenching and tempering, the bolts gain improved strength and resistance to wear and deformation. Finally, the bolts are finished according to customer specifications, which may include galvanization or other protective coatings to prevent corrosion.

Advantages of Carbon Steel Stud Bolts

carbon steel stud bolt factories

One of the primary advantages of carbon steel stud bolts is their excellent tensile and yield strength. This characteristic allows them to withstand significant loads, making them suitable for applications ranging from structural installations to machinery assembly. Additionally, carbon steel is more affordable compared to stainless steel or other alloys, making it an attractive option for large-scale projects.

Carbon steel stud bolts also feature good machinability, allowing for precise manufacturing and customization. Factories can produce bolts in various sizes and specifications to meet the unique needs of different industries. Furthermore, the ability to apply protective coatings enhances the corrosion resistance of carbon steel, extending the lifespan of the fasteners, especially in hostile environments.

The Role of Carbon Steel Stud Bolt Factories in Industries

Carbon steel stud bolt factories play a vital role in multiple sectors, including construction, automotive, aerospace, and manufacturing. In construction, they are indispensable for securing structural components, ensuring the stability and safety of buildings and bridges. In the automotive and aerospace industries, these fasteners are critical in assembling various components, emphasizing safety and reliability.

Moreover, the ongoing demand for carbon steel stud bolts highlights the importance of these factories in supporting industrial growth and innovation. As technology continues to advance, these factories are expected to adopt more sophisticated manufacturing techniques, further improving the quality and performance of carbon steel stud bolts.

Conclusion

In summary, carbon steel stud bolt factories are essential players in the fastener manufacturing industry. By utilizing high-quality materials and advanced production processes, they provide robust fasteners that meet the diverse needs of various sectors. With their durability, cost-effectiveness, and adaptability, carbon steel stud bolts will continue to be a cornerstone in industrial applications, underscoring the importance of these specialized manufacturing facilities.

Latest news

-

Automatic Flush Bolts for Double Doors - Reliable Security, Easy Installation, Factory Direct Supply

NewsJul.05,2025

-

High-Quality 11mm Bolts Manufacturer Reliable 11mm Bolts Factory & Suppliers

NewsJul.05,2025

-

High-Quality DIN975 Thread Rods Manufacturer Reliable Factory & Suppliers

NewsJul.05,2025

-

High-Quality Strut Washers – Reliable Strut Washers Factory & Trusted Company Suppliers

NewsJul.04,2025

-

Premium Wood Screws for Flooring - Reliable Wood Floor Screws Company & Suppliers

NewsJun.24,2025

-

High-Quality Cabinet Bolts – Reliable Factory, Trusted Company & Leading Suppliers

NewsJun.10,2025