7 8 anchor bolts suppliers

Ara . 19, 2024 15:57 Back to list

7 8 anchor bolts suppliers

Understanding 7% to 8% Anchor Bolts A Comprehensive Guide for Suppliers

Anchor bolts play a crucial role in construction and engineering, providing the foundational support needed to hold structures together. Among various specifications, the 7% to 8% classification of anchor bolts stands out due to its material and performance characteristics. This article aims to shed light on what these specifications mean, their applications, and what suppliers need to keep in mind when sourcing or manufacturing these essential components.

The Importance of Anchor Bolts

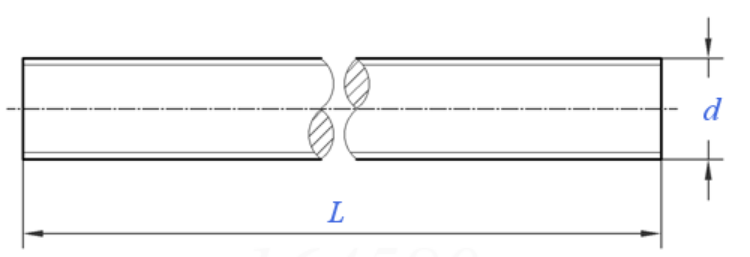

Anchor bolts are used to attach objects or structures to concrete, providing stability and strength. They come in various shapes, sizes, and grades, tailored to meet specific demands. In general, anchor bolts can be classified into two main categories headed bolts and bent bolts. The choice between the two depends on the design requirements and structural conditions.

Among the many classifications of anchor bolts, those that comprise 7% to 8% of specific materials, usually referring to their carbon content, have become prevalent due to their balance of strength and ductility. Increasing carbon content typically enhances the mechanical properties, making these bolts suitable for high-stress applications.

Specifications and Material Properties

A critical aspect of anchor bolt specifications is their material composition. In the 7% to 8% category, such bolts typically consist of carbon steel with a mix of alloying elements that enhance their properties. Carbon content plays a significant role in determining yield strength, tensile strength, and ductility.

For instance, bolts with a carbon content of around 7% often showcase a good balance between strength and flexibility, making them ideal for dynamic loads where movement and vibrations are expected. Bolts higher in carbon content (around 8%) tend to offer greater tensile strength, making them suitable for static and heavy-load applications.

The manufacturing process, typically involving hot or cold forging, further influences the final mechanical properties of these bolts. Suppliers need to ensure that their products conform to relevant standards, such as ASTM A325 or A490, which dictate mechanical properties crucial for structural integrity.

Applications of 7% to 8% Anchor Bolts

Anchor bolts in the 7% to 8% range find application across various industries, including

1. Construction Used in fixing steel frameworks, bridges, towers, and other load-bearing structures.

7 8 anchor bolts suppliers

2. Infrastructure Vital for securing transmission towers and telecommunication masts that face environmental stress.

4. Marine Applications Their resistance to corrosion makes them suitable for docks and offshore structures, where environmental factors can lead to material degradation.

Choosing the Right Supplier

For buyers and businesses seeking anchor bolts within the 7% to 8% carbon content range, selecting the right supplier is critical. Consider the following factors

1. Quality Assurance Verify that the supplier adheres to industry standards for manufacturing and testing.

2. Customization Check if the supplier offers custom solutions, as different projects may require specific bolt dimensions or coatings.

3. Reputation Look for suppliers with positive feedback in the industry, indicating reliability and quality.

4. Delivery Capabilities Timely delivery is crucial in construction projects. Ensure that the supplier has the capacity to meet project deadlines.

5. Material Traceability Suppliers should maintain detailed records of material sources and processes to ensure that the bolts meet all required specifications.

Conclusion

7% to 8% anchor bolts are integral to modern construction and engineering projects, providing the necessary strength and stability for various applications. Understanding their material properties, specifications, and the supplier's role in providing quality products is essential for engineers, architects, and project managers. As demands for stronger and more reliable anchor solutions grow, the importance of sourcing the right materials from reputable suppliers cannot be overstated. By prioritizing quality, customization, and delivery from suppliers, businesses can ensure the success of their projects while maintaining safety and structural integrity.

Latest news

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025