astm a325 bolts

Feb . 11, 2025 06:40 Back to list

astm a325 bolts

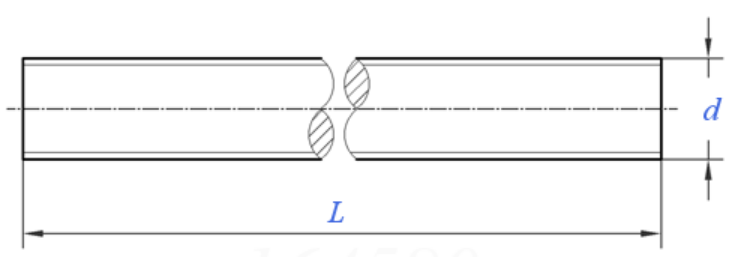

ASTM A325 bolts are widely recognized in the construction and engineering field as the gold standard when it comes to high-strength fasteners. With their superior design and material specifications, these bolts are an essential component in a variety of structural applications, providing unparalleled stability and security. This article will delve into the exceptional qualities, applications, and advantages of ASTM A325 bolts, highlighting their importance in modern engineering.

Safety and Assurance The Advantages of ASTM A325 Bolts The predominant advantage of ASTM A325 bolts lies in their ability to offer high-load performance with a relatively low profile design, making them ideal for projects where space is a constraint. Additionally, their manufacturing under stringent standards eliminates the risk of premature failure, which could have catastrophic consequences in structural applications. This ensures not only safety but also longevity, saving costs in the long run by minimizing maintenance and replacement needs. A Trustworthy Choice Ensuring Compliance and Quality Purchasing ASTM A325 bolts from a verified and reputable supplier is crucial as it ensures compliance with international quality standards. Suppliers who adhere strictly to the established specifications can provide certificates of compliance, giving consumers added assurance and allowing engineers to proceed with confidence in their design implementations. In Conclusion A Testament to Reliability ASTM A325 bolts are indispensable to the engineering world, providing secure and stable connections in critical structures. Their superior strength, outstanding durability, and exceptional reliability endear them to engineers and architects worldwide. By choosing ASTM A325 bolts, professionals are making a commitment to quality and safety, ensuring their projects stand the test of time. As the demand for robust infrastructure continues to rise, the pivotal role of ASTM A325 bolts in achieving engineering excellence becomes increasingly apparent.

Safety and Assurance The Advantages of ASTM A325 Bolts The predominant advantage of ASTM A325 bolts lies in their ability to offer high-load performance with a relatively low profile design, making them ideal for projects where space is a constraint. Additionally, their manufacturing under stringent standards eliminates the risk of premature failure, which could have catastrophic consequences in structural applications. This ensures not only safety but also longevity, saving costs in the long run by minimizing maintenance and replacement needs. A Trustworthy Choice Ensuring Compliance and Quality Purchasing ASTM A325 bolts from a verified and reputable supplier is crucial as it ensures compliance with international quality standards. Suppliers who adhere strictly to the established specifications can provide certificates of compliance, giving consumers added assurance and allowing engineers to proceed with confidence in their design implementations. In Conclusion A Testament to Reliability ASTM A325 bolts are indispensable to the engineering world, providing secure and stable connections in critical structures. Their superior strength, outstanding durability, and exceptional reliability endear them to engineers and architects worldwide. By choosing ASTM A325 bolts, professionals are making a commitment to quality and safety, ensuring their projects stand the test of time. As the demand for robust infrastructure continues to rise, the pivotal role of ASTM A325 bolts in achieving engineering excellence becomes increasingly apparent.

Latest news

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025