12 inch lag bolts companies

ఫిబ్ర . 15, 2025 04:32 Back to list

12 inch lag bolts companies

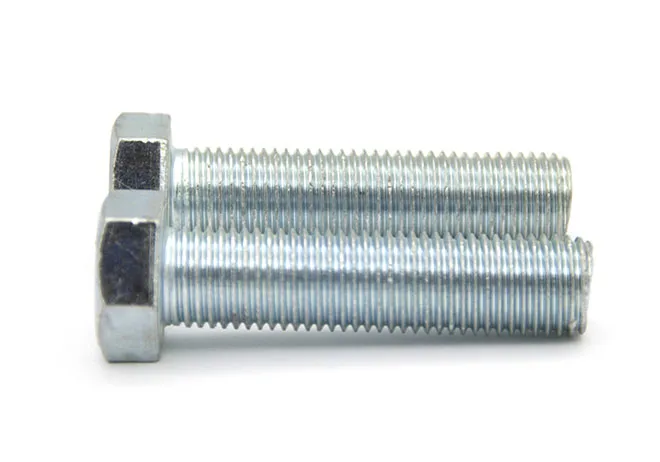

UNF bolts, standing for Unified National Fine threads, are a quintessential tool in the world of fasteners. In engineering and construction, they are favored for their application where precision and reliability are paramount. Unlike the more coarse thread counterparts, UNF bolts are designed with a finer thread pitch, which offers several performance advantages critical to certain applications.

Installation of UNF bolts can require some expertise due to the precision fit. Over-torquing can strip the fine threads, rendering the bolt useless. Thus, understanding the correct torque settings and employing calibrated tools is essential. It’s also vital to maintain thread cleanliness, as debris can interfere with the thread engagement and compromise the bolt’s functionality. Maintenance and inspection are additional factors that underscore the expertise involved in working with UNF bolts. Regular inspections for fatigue or damage are necessary to ensure long-term reliability. Often, visual inspections are complemented by non-destructive testing techniques such as ultrasonic testing to detect potential failures that are not visible to the naked eye. For businesses, the integration of UNF bolts into product design requires consideration of cost versus benefit. Although they may be more expensive than coarse-thread alternatives, their durability and reliability can lead to cost savings in the long term by reducing maintenance needs and preventing failures that could incur greater costs. When selecting a supplier for UNF bolts, it is critical to consider their reputation, expertise, and quality assurance processes. Companies with ISO certifications and rigorous quality control protocols can provide assurance that their products meet stringent industry standards. Engaging with suppliers for technical support and understanding the specifications suited for your particular application can enhance the utility of these fasteners. In summary, UNF bolts are indispensable in applications demanding precision and durability. Their fine threads offer superior holding power and higher tensile strength, making them an excellent choice for high-stress environments. However, to maximize their benefits, one must approach their usage with careful consideration to material selection, installation precision, and ongoing maintenance. Mastery in the use of UNF bolts not only reflects engineering expertise but also contributes to the overall safety and efficacy of the constructs they support.

Installation of UNF bolts can require some expertise due to the precision fit. Over-torquing can strip the fine threads, rendering the bolt useless. Thus, understanding the correct torque settings and employing calibrated tools is essential. It’s also vital to maintain thread cleanliness, as debris can interfere with the thread engagement and compromise the bolt’s functionality. Maintenance and inspection are additional factors that underscore the expertise involved in working with UNF bolts. Regular inspections for fatigue or damage are necessary to ensure long-term reliability. Often, visual inspections are complemented by non-destructive testing techniques such as ultrasonic testing to detect potential failures that are not visible to the naked eye. For businesses, the integration of UNF bolts into product design requires consideration of cost versus benefit. Although they may be more expensive than coarse-thread alternatives, their durability and reliability can lead to cost savings in the long term by reducing maintenance needs and preventing failures that could incur greater costs. When selecting a supplier for UNF bolts, it is critical to consider their reputation, expertise, and quality assurance processes. Companies with ISO certifications and rigorous quality control protocols can provide assurance that their products meet stringent industry standards. Engaging with suppliers for technical support and understanding the specifications suited for your particular application can enhance the utility of these fasteners. In summary, UNF bolts are indispensable in applications demanding precision and durability. Their fine threads offer superior holding power and higher tensile strength, making them an excellent choice for high-stress environments. However, to maximize their benefits, one must approach their usage with careful consideration to material selection, installation precision, and ongoing maintenance. Mastery in the use of UNF bolts not only reflects engineering expertise but also contributes to the overall safety and efficacy of the constructs they support.

Latest news

-

Premium Wire Bolts Suppliers | High-Quality Bolts

NewsAug.05,2025

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025