Manufacturers of Set Screws for Door Knobs and Related Hardware Solutions

Desemba . 05, 2024 08:27 Back to list

Manufacturers of Set Screws for Door Knobs and Related Hardware Solutions

Understanding Set Screws for Door Knobs A Detailed Insight into Manufacturing and Applications

In the world of hardware, the significance of set screws, particularly those used in door knobs, cannot be overstated. Set screws are essential components that secure the functional parts of door knobs, ensuring they operate smoothly and reliably. This article will delve into the intricacies of set screws, their manufacturing process, and their crucial role in the functionality of door knobs.

What are Set Screws?

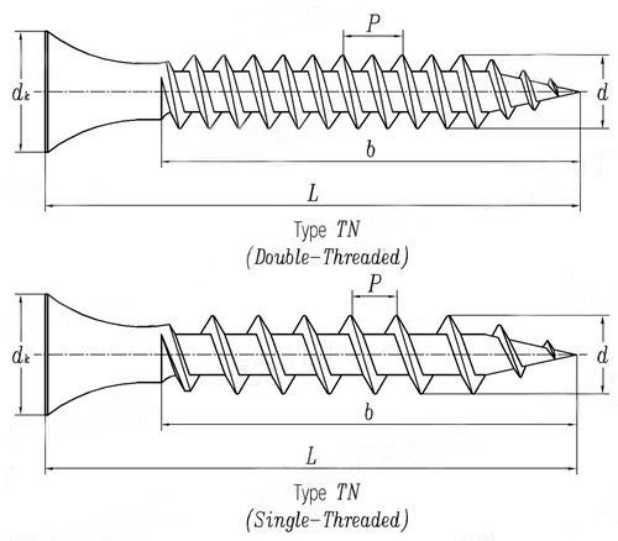

Set screws are cylindrical fasteners characterized by a head that is often hexagonal or slotted, allowing for easy installation and removal using a wrench or screwdriver. Unlike conventional screws that penetrate a surface, set screws are designed to be inserted into a threaded hole and press against an object, often a shaft. This creates a friction fit that prevents movement, making them ideal for securing door knobs to their spindles.

The materials used for set screws can vary, including stainless steel, carbon steel, and brass, depending on the intended application and environment. The choice of material affects the screw's strength, corrosion resistance, and aesthetic appeal. For example, stainless steel set screws provide superior rust resistance, making them suitable for outdoor installations.

The Manufacturing Process of Set Screws

Producing set screws involves several stages, ensuring each screw meets strict quality and performance standards. Here’s a breakdown of the typical manufacturing process

1. Material Selection The first step involves selecting the right material based on the required properties, such as strength, wear resistance, and corrosion resistance.

2. Forging or Cold Heading Depending on the manufacturer's preference, set screws are either forged or formed through a process known as cold heading. Cold heading is a cost-effective method where the material is shaped at room temperature, resulting in minimal waste.

3. Threading After forming, the next stage is threading. This is typically done using a die, which creates the helical grooves that allow the screws to engage with threaded holes securely.

set screws for door knobs factories

4. Heat Treatment To enhance the mechanical properties of the set screws, heat treatment is often employed. This process involves heating the screws to a specific temperature and then allowing them to cool, which improves their hardness and strength.

5. Surface Finishing Finally, the screws undergo surface finishing processes such as plating or coating to improve corrosion resistance and aesthetic appeal. Common finishes include zinc plating, black oxide, or powder coating.

6. Quality Control Before they are packaged and shipped, set screws are subjected to rigorous quality control checks, including dimensional inspections and mechanical testing, to ensure they meet industry standards.

Applications of Set Screws in Door Knobs

Set screws play a pivotal role in the assembly of door knobs. When a door knob is installed, the set screw is tightened to secure the knob to the spindle. This mechanism allows for the easy installation and removal of door knobs, making them accessible for maintenance or replacement without complex disassembly.

Different types of door knobs—be it lever handles, traditional round knobs, or even electronic locks—utilize set screws for their functionality. In residential, commercial, and industrial settings, the reliability of set screws to hold these knobs firmly in place is crucial, as door knobs must withstand frequent use and the forces exerted upon them.

Moreover, as design trends evolve and manufacturers strive to create more innovative door knob mechanisms, the role of set screws will continue to adapt. Recent advancements may include the incorporation of security features that prevent tampering or unauthorized access. In such cases, the design and manufacture of set screws will also evolve to meet these new challenges.

Conclusion

Set screws are unsung heroes in the world of door hardware, playing a fundamental role in ensuring the reliability and functionality of door knobs. Understanding the manufacturing process behind these small but mighty components sheds light on their quality and importance in everyday applications. As technology advances and design requirements shift, set screws will remain essential in securing our door hardware, making them integral to both traditional and modern door solutions. Factories dedicated to producing these vital components are crucial in maintaining the standards and innovations required in today's marketplace.

Latest news

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025