high quality aerospace washers

Septemba . 25, 2024 02:56 Back to list

high quality aerospace washers

High-Quality Aerospace Washers Essential Components for Safety and Reliability

In the aerospace industry, where precision, safety, and reliability are paramount, every component plays a critical role in the overall performance of aircraft. Among these components, aerospace washers are often overlooked despite their significant contributions to the integrity and functionality of various systems. High-quality aerospace washers are essential for ensuring that fasteners maintain their position, distribute loads evenly, and prevent vibration-induced loosening.

Understanding Aerospace Washers

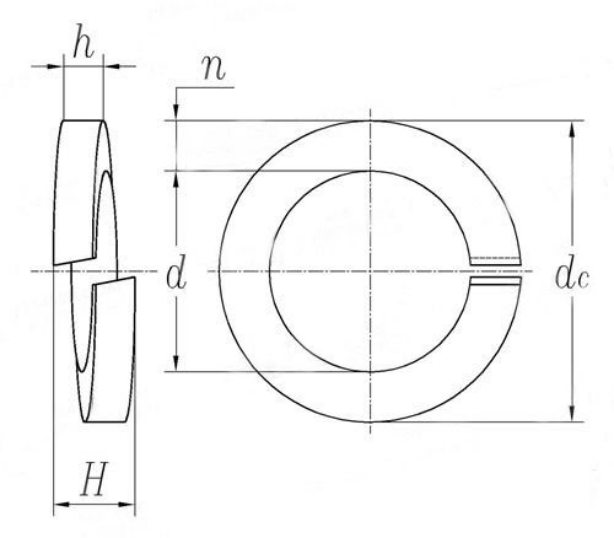

Aerospace washers are thin, flat discs made from various materials, including metals and plastics. They are utilized in conjunction with bolts, nuts, and screws to provide critical functions such as load distribution, sealing, and protection. In the aerospace context, washers come in different shapes—such as flat washers, lock washers, and sealing washers—each designed for specific applications to meet rigorous performance requirements.

The Importance of Quality

Quality in aerospace washers cannot be overstated. Given the high-stakes environment in which they operate, these components must meet stringent industry standards. High-quality washers are manufactured using advanced techniques and materials that enhance their durability and resilience. Common materials for aerospace washers include stainless steel, titanium, and aerospace-grade polymers. The choice of material is crucial, as it influences the wash's weight, strength, resistance to corrosion, and temperature stability.

The Role of Washers in Load Distribution

One of the primary functions of aerospace washers is load distribution. When a fastener is tightened, it exerts pressure on the joint surfaces. Without washers, this pressure could lead to deformation of the materials, compromising the joint's integrity. Aerospace washers help distribute this load over a larger area, minimizing the risk of damage to both the fastener and the components being secured. This load distribution is vital in high-stress situations, such as during takeoff, cruising, and landing, where vibrations and changing loads can impact the structural integrity of an aircraft.

high quality aerospace washers

Preventing Vibration-Induced Loosening

Vibrations are an inherent part of aircraft operation. High-quality aerospace washers, particularly lock washers, play a significant role in preventing the loosening of fasteners caused by these vibrations. Lock washers create a mechanical interlocking effect between the fastener and the surface, ensuring a more secure fit. This feature not only enhances safety but also reduces maintenance downtime, as loose fasteners can lead to costly repairs and replacements.

Sealing Properties

In addition to load distribution and vibration prevention, certain types of aerospace washers also provide sealing capabilities. Sealing washers prevent leakage of fluids or gases, which is critical in many aerospace applications. This function is particularly important in fuel systems and hydraulic systems, where even minor leaks can lead to significant safety hazards. High-quality sealing washers are designed to withstand extreme temperatures and mechanical stress, ensuring that seals remain intact throughout the aircraft's lifecycle.

Compliance with Industry Standards

High-quality aerospace washers are manufactured in compliance with industry regulations and certifications. Organizations such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) set strict guidelines to ensure that all components used in aerospace applications adhere to safety and reliability standards. Manufacturers that prioritize quality control and adhere to these standards are more likely to produce washers that can withstand the demanding environments of aerospace applications.

Conclusion

In conclusion, high-quality aerospace washers are indispensable components in the aviation sector, contributing significantly to the safety, reliability, and overall performance of aircraft. Their roles in load distribution, vibration prevention, and sealing cannot be underestimated, as they are critical in maintaining the integrity of fastened joints under various operational conditions. With ongoing advancements in materials and manufacturing processes, the aerospace industry continues to innovate, ensuring that these small yet vital components remain robust and reliable. As the aviation sector evolves, the demand for high-quality aerospace washers will only grow, making them an essential focus for manufacturers and engineers dedicated to ensuring the highest levels of safety in flight.

Latest news

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025