double end threaded stud bolt

Desemba . 12, 2024 11:03 Back to list

double end threaded stud bolt

The Importance of Double End Threaded Stud Bolts in Modern Engineering

In the realm of engineering and construction, the choice of fasteners is crucial for the integrity and functionality of various structures and machines. Among the myriad types of fasteners, double end threaded stud bolts stand out due to their unique design and versatile applications. This article will delve into the features, advantages, applications, and considerations surrounding double end threaded stud bolts, highlighting their significance in modern engineering.

What are Double End Threaded Stud Bolts?

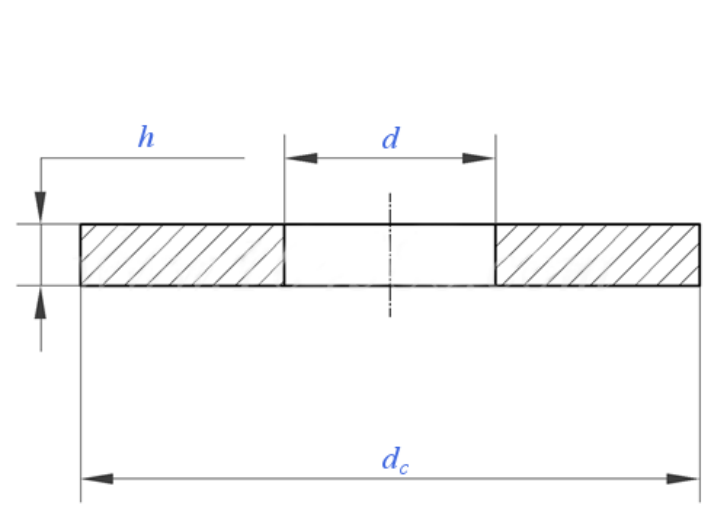

Double end threaded stud bolts, commonly known simply as stud bolts, are fasteners characterized by their threaded ends, which extend from a central unthreaded section. Unlike traditional bolts, which have a head on one end, stud bolts are fully threaded on both ends. This design allows for compatibility with a variety of nuts and can be utilized in numerous assembly configurations.

Typically, stud bolts come in standard lengths and diameters, but they can also be custom-manufactured to meet specific requirements. The materials used to fabricate these bolts vary widely, including carbon steel, stainless steel, and alloy steel, depending on the application environment and loads they must endure.

Advantages of Using Double End Threaded Stud Bolts

1. Enhanced Load Distribution One of the primary benefits of stud bolts is their ability to distribute load more evenly across the joint. Because they are installed with nuts on both ends, the pressure exerted is shared, which minimizes the risk of localized material failure.

2. Versatile Applications Double end threaded stud bolts find applications across a multitude of industries, including construction, automotive, oil and gas, and manufacturing. They are ideal for securing flanged connections, holding together structural components, and in machinery that experiences vibration and movement.

3. Ease of Installation The threaded design allows for straightforward installation. Stud bolts can be positioned in place without the need for a head, making them particularly useful in confined spaces or where access is limited.

4. Adjustability The use of nuts on both ends enables adjustments during installation. If a connection needs to be tightened or loosened, the nuts can be turned without removing the entire bolt from the assembly.

double end threaded stud bolt

Applications in Various Industries

Double end threaded stud bolts have become essential in several sectors. In the oil and gas industry, these bolts are crucial for joining components of pipelines and pressure vessels, which require robust and reliable fastening solutions to handle high pressures and extreme temperatures.

In the construction sector, they are used extensively in the assembly of steel structures, such as bridges and high-rise buildings. Their ability to support heavy loads while offering flexibility in installation makes them a preferred choice among engineers.

In the automotive sector, stud bolts are used in engine components, ensuring that various parts remain securely fastened, even under the harsh operating conditions of an engine bay. The aerospace industry similarly relies on stud bolts for their critical role in assembling airframes and engine components, where precision and reliability are paramount.

Considerations in Selection and Use

While double end threaded stud bolts offer numerous advantages, some considerations must be taken into account during selection and installation. The appropriate material must be chosen based on the environmental conditions and load requirements. Furthermore, correct torque specifications must be adhered to during installation to avoid issues such as bolt failure or joint separation.

It is also crucial for engineers and constructors to ensure that the threading is compatible with the nuts being used, as mismatched threads can lead to premature wear or failure. Regular inspections should also be conducted to assess the integrity of stud bolts, especially in high-stress environments.

Conclusion

In conclusion, double end threaded stud bolts are a vital component in modern engineering, recognized for their strength, versatility, and ease of installation. As industries continue to evolve and demand robust solutions for complex projects, the importance of selecting the right fasteners, including stud bolts, cannot be overstated. Their capacity to provide reliable and adjustable connections will undoubtedly keep them at the forefront of engineering innovations in the years to come.

Latest news

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025