stud bolt 3 4

нов . 20, 2024 19:24 Back to list

stud bolt 3 4

The Evolution and Significance of Stud Bolts in Engineering

Stud bolts are essential fasteners in various industries, playing a crucial role in ensuring the integrity and safety of structures and machinery. With roots tracing back to ancient engineering practices, stud bolts have evolved significantly, adapting to meet the ever-increasing demands of modern technology, specifically in sectors like construction, automotive, and aerospace.

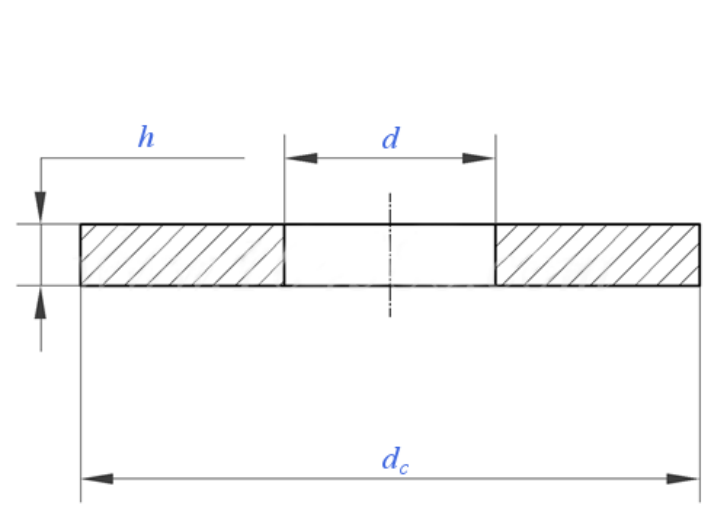

A stud bolt is defined as a cylindrical bolt that is threaded along its entire length or partially. Unlike standard bolts that consist of a head and shank, stud bolts are designed to be installed into a pre-tapped hole or used with nuts. This design offers distinct advantages, such as greater load distribution, ease of installation in tight spaces, and the ability to securely fasten multiple components at once.

Types of Stud Bolts

Stud bolts come in various types and sizes, with the most common being the metric and imperial systems. Their classification is often determined by their dimensions, material composition, and strength characteristics. Common types include fully threaded stud bolts, which are utilized for greater tensile strength, and partially threaded stud bolts, which are used when shear strength is more critical than tension.

Materials also play a significant role in the functionality of stud bolts. Typically made from carbon steel, stainless steel, or alloy steel, the choice of material affects factors like resistance to corrosion, high-temperature performance, and overall durability. Stainless steel stud bolts, for instance, are favored in marine and chemical industries due to their excellent resistance to the elements and corrosive substances.

stud bolt 3 4

Applications and Importance

The significance of stud bolts cannot be overstated. In the construction industry, they are widely used in structural connections, anchoring steel beams and columns, ensuring that edifices can withstand both tensile and shear forces. In the automotive sector, stud bolts hold together vital components, such as engine parts and suspension systems, ensuring a reliable performance under various conditions. Similarly, in aerospace applications, they play a key role in assembly processes, where strength and reliability are paramount.

One notable advantage of stud bolts is their ability to be easily inspected and replaced. In applications where maintenance is crucial, such as in oil rigs and power plants, stud bolts can be quickly assessed for wear and damage, facilitating timely maintenance and reducing downtime.

Challenges and Future Directions

Despite their significance, the use of stud bolts is not without challenges. Issues such as galling (seizing) when stainless steel is paired with similar materials and misalignment during installation can arise. However, advancements in coatings and surface treatments are being developed to mitigate these problems and enhance performance.

In conclusion, stud bolts are vital components that have endured the test of time, adapting to the needs of various industries. Their unique design, versatility, and reliability make them indispensable in ensuring structural integrity and operational functionality. As technology continues to advance, so too will the designs and materials used in the production of stud bolts, paving the way for even more innovative applications in the future.

Latest news

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025