3 8 bolts and nuts suppliers

Dez . 28, 2024 00:00 Back to list

3 8 bolts and nuts suppliers

The Importance of Sourcing Quality Bolts and Nuts from Suppliers

In the world of manufacturing and construction, the significance of high-quality bolts and nuts cannot be overstated. These small yet vital components are essential for ensuring the integrity, safety, and durability of various structures and machinery. When businesses engage with suppliers for bolts and nuts, they must consider several factors, including quality, availability, cost, and reliability. In this article, we will explore the importance of sourcing bolts and nuts from reputable suppliers, focusing on what can be achieved by understanding the market and maintaining robust supplier relationships.

The Role of Bolts and Nuts in Industry

Bolts and nuts serve as fasteners that hold structures and components together, making them fundamental to engineering and construction projects. They play a crucial role in applications ranging from automobile manufacturing to large-scale structural projects, such as bridges and buildings. Choosing the right fasteners is crucial to ensure that assemblies are secure and can withstand various stresses, including tension, shear, and vibration.

Quality Matters

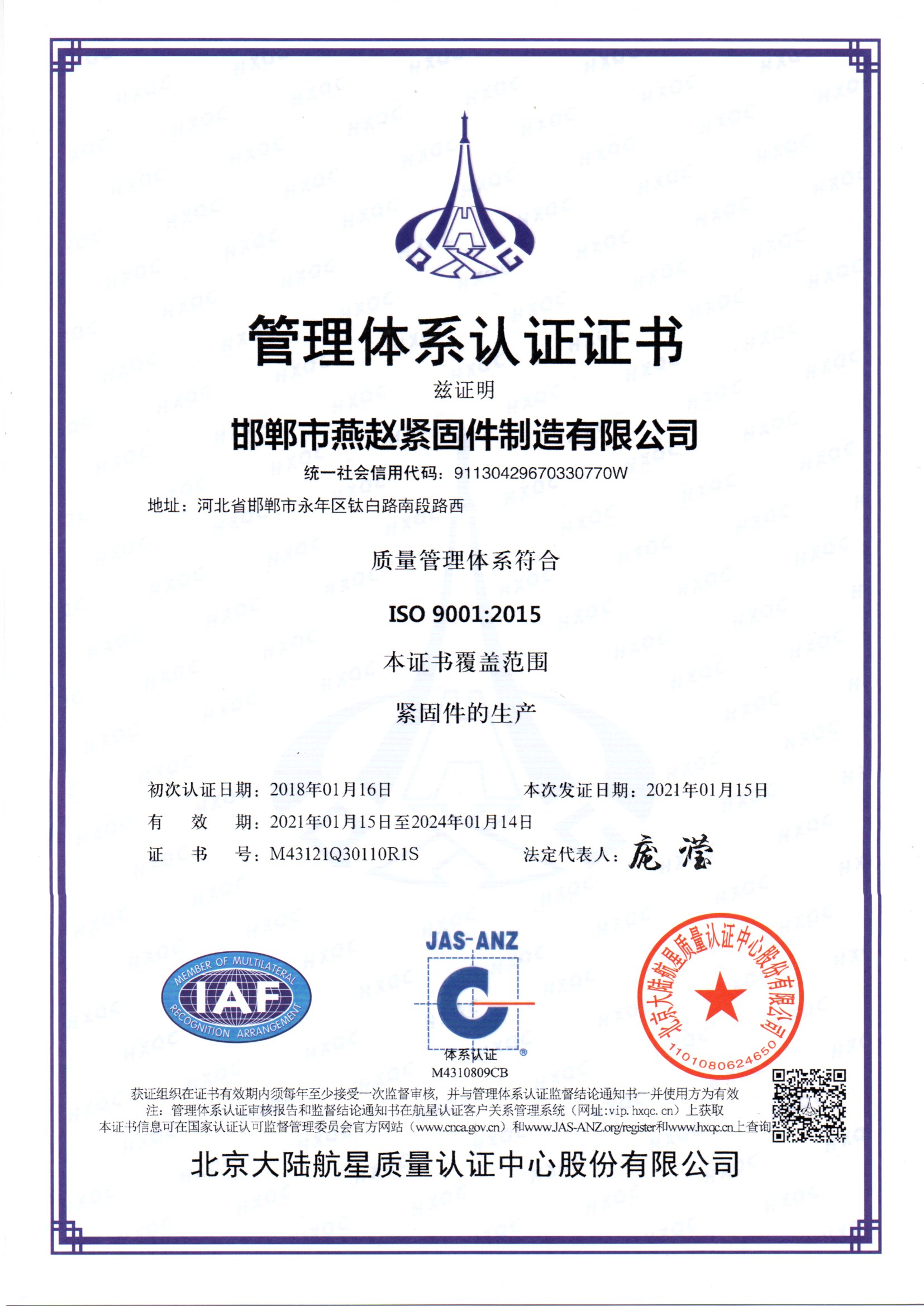

The quality of bolts and nuts directly impacts the safety and performance of the final product. Poor-quality fasteners can lead to failures, which might result in costly downtime, repairs, or even catastrophic accidents. Thus, sourcing components from suppliers that adhere to stringent quality control processes is vital. Reliable suppliers often provide certifications, ensuring their products meet industry standards and specifications.

Understanding Market Trends

The market for bolts and nuts is influenced by several factors, including technological advancements, raw material prices, and global demand. A thorough understanding of these market trends can help businesses make informed decisions about sourcing. For example, the shift towards sustainable materials may lead manufacturers to seek eco-friendly bolts and nuts made from recycled materials or designed to minimize environmental impact. Staying abreast of these trends can provide a competitive edge.

3 8 bolts and nuts suppliers

Building Strong Supplier Relationships

Establishing robust relationships with suppliers is essential for ensuring a steady supply of quality bolts and nuts. Communication is key; businesses should maintain an open dialogue with suppliers regarding their needs, delivery schedules, and product specifications. A good supplier can offer insights into new products, trends, or potential challenges in the supply chain. By forming partnerships rather than simply transactional relationships, businesses can ensure they have access to the best materials available.

Evaluating Supplier Performance

Regularly assessing supplier performance is crucial to ensure continued quality and reliability. This can involve monitoring delivery times, the quality of products received, and responsiveness to issues or concerns. Setting clear expectations and performance metrics from the outset can help streamline the evaluation process. In cases where a supplier fails to meet these expectations, having backup suppliers in place can mitigate risks associated with delays or quality issues.

Cost Considerations

While quality is paramount, cost is also a significant factor. Businesses must balance the need for quality fasteners with budget constraints. Engaging with multiple suppliers can provide valuable insights into pricing trends and enable comparisons that lead to better purchasing decisions. It's also essential to consider the total cost of ownership, which includes factors such as installation time, long-term durability, and potential replacement costs.

Conclusion

In conclusion, the sourcing of bolts and nuts from suppliers is a critical aspect of many industries that should not be overlooked. By prioritizing quality, understanding market trends, building strong relationships with suppliers, regularly evaluating supplier performance, and considering cost factors, businesses can enhance their operations and ensure the safety and reliability of their products. As the industrial landscape continues to evolve, staying agile and informed in sourcing practices will be vital for success in a competitive marketplace. By focusing on these key areas, companies can secure the best possible outcomes with their fastener needs, ultimately resulting in improved performance and growth.

Latest news

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025