oem self sealing bolts

Sep . 15, 2024 01:54 Back to list

oem self sealing bolts

Understanding OEM Self-Sealing Bolts A Key Component in Modern Manufacturing

In the dynamic realm of manufacturing, the quest for reliability and efficiency is paramount. One of the unsung heroes in achieving these objectives is the OEM (Original Equipment Manufacturer) self-sealing bolt. These specialized fasteners are engineered to enhance performance, durability, and safety, making them an essential component in various industries, from automotive to aerospace and beyond.

What are Self-Sealing Bolts?

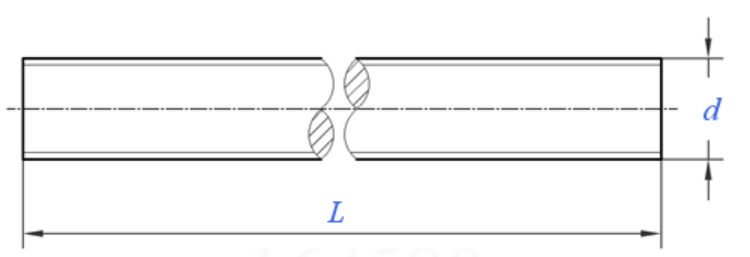

Self-sealing bolts, as the name suggests, possess a unique feature that allows them to create a seal upon tightening. This characteristic is primarily attributed to their design and the materials used in their production. Typically, these bolts are equipped with a rubber or polymer seal that compresses when the bolt is tightened, effectively preventing leaks of fluids, gases, or other substances. This sealing capability is critical in applications where even the slightest leakage could lead to catastrophic failures or safety hazards.

Advantages of Using OEM Self-Sealing Bolts

1. Enhanced Reliability One of the primary advantages of self-sealing bolts is their ability to provide a reliable seal. In sectors like automotive and aerospace, where components are subjected to high pressures and varying environmental conditions, the integrity of joints is vital. Self-sealing bolts minimize the risk of joint failure, thereby enhancing the overall reliability of the assembly.

2. Time and Cost Efficiency Utilizing self-sealing bolts can lead to significant time and cost savings in the manufacturing process. The elimination of secondary sealing operations, such as the application of sealants or gaskets, streamlines the assembly process. This reduction in additional steps not only saves time but also reduces material costs, making it a cost-effective solution.

oem self sealing bolts

3. Versatility OEM self-sealing bolts are designed to meet various specifications and requirements across different industries. They can be manufactured in multiple sizes, shapes, and materials, allowing them to be tailored to specific applications. This versatility ensures that manufacturers can find suitable self-sealing solutions for their unique engineering challenges.

4. Resistance to Corrosion Many self-sealing bolts are made from materials that are resistant to corrosion, ensuring longevity and durability. This is particularly important in harsh environments, such as marine applications or chemical processing plants, where exposure to corrosive substances can lead to premature failure of traditional fasteners.

Applications Across Industries

The versatility and efficiency of OEM self-sealing bolts make them invaluable in various applications. In the automotive industry, they are commonly used in engines, fuel systems, and hydraulic systems where robust sealing is crucial. In aerospace, self-sealing bolts are employed to ensure the structural integrity of aircraft components, where weight and safety are critical factors. Additionally, these bolts find applications in construction, manufacturing machinery, and oil and gas exploration, among other sectors.

Conclusion

As industries continue to evolve and demand higher standards of safety and efficiency, the role of OEM self-sealing bolts will undoubtedly expand. Their ability to provide reliable sealing solutions, combined with the advantages of cost-effectiveness and versatility, positions them as a vital component in modern manufacturing. As engineers and manufacturers seek innovative ways to enhance product design, self-sealing bolts will stand out as a key solution in achieving operational excellence.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025