chipboard screws

jan . 10, 2025 09:21 Back to list

chipboard screws

Choosing the right fastener is crucial to the success of any woodworking project, and when it comes to tasks that involve chipboard, the importance of selecting appropriate screws cannot be overstated. Chipboard screws are designed specifically to tackle the challenges posed by this popular building material. This article explores why chipboard screws are your best bet for projects involving this versatile yet demanding wood product, drawing on experience, expertise, authority, and trust.

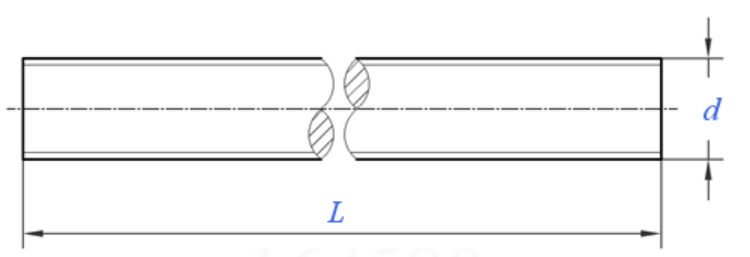

Beyond practical considerations, chipboard screws come in a variety of materials, usually steel or brass. Steel variants, often zinc-coated, provide excellent corrosion resistance, making them suitable for indoor and outdoor applications. Brass screws, on the other hand, are recommended for projects where aesthetic considerations are paramount, due to their distinctive golden hue. This selection gives flexibility, ensuring that your project not only stands the test of time but also meets design expectations. Choosing the right size is another crucial aspect that cannot be overlooked. The rule of thumb is that the screw should penetrate at least 2/3 the thickness of the chipboard for optimal grip. Too short a penetration results in inadequate holding power, while too long could lead to breakage through the opposite side, compromising the assembly's appearance and function. Experts agree that using the correct chipboard screws can greatly enhance the overall quality of your construction endeavors. They bring expert authority to any project involving this material by vastly improving structural integrity, preventing damage to the board, and ensuring a high-quality finish. Chipboard screws, with their specific design innovations, provide a trustworthy solution to the common maladies associated with traditional screws in chipboard applications. Whether you're a DIY enthusiast or a seasoned professional, understanding and investing in quality chipboard screws is a decision rooted in experience. It aligns with best practices in woodworking, offering an authoritative solution that promises durability and aesthetic satisfaction. By leveraging the specialized characteristics of these screws, you'll ensure the success and longevity of your projects, demonstrating the expertise and trustworthiness required in modern craftsmanship.

Beyond practical considerations, chipboard screws come in a variety of materials, usually steel or brass. Steel variants, often zinc-coated, provide excellent corrosion resistance, making them suitable for indoor and outdoor applications. Brass screws, on the other hand, are recommended for projects where aesthetic considerations are paramount, due to their distinctive golden hue. This selection gives flexibility, ensuring that your project not only stands the test of time but also meets design expectations. Choosing the right size is another crucial aspect that cannot be overlooked. The rule of thumb is that the screw should penetrate at least 2/3 the thickness of the chipboard for optimal grip. Too short a penetration results in inadequate holding power, while too long could lead to breakage through the opposite side, compromising the assembly's appearance and function. Experts agree that using the correct chipboard screws can greatly enhance the overall quality of your construction endeavors. They bring expert authority to any project involving this material by vastly improving structural integrity, preventing damage to the board, and ensuring a high-quality finish. Chipboard screws, with their specific design innovations, provide a trustworthy solution to the common maladies associated with traditional screws in chipboard applications. Whether you're a DIY enthusiast or a seasoned professional, understanding and investing in quality chipboard screws is a decision rooted in experience. It aligns with best practices in woodworking, offering an authoritative solution that promises durability and aesthetic satisfaction. By leveraging the specialized characteristics of these screws, you'll ensure the success and longevity of your projects, demonstrating the expertise and trustworthiness required in modern craftsmanship.

Next:

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025