zinc plated bolts manufacturer

Dec . 07, 2024 05:00 Back to list

zinc plated bolts manufacturer

The Role of Zinc Plated Bolts in Modern Manufacturing

In today's fast-paced manufacturing environment, the need for durable and reliable components is paramount. One significant player in the field of fastening solutions is zinc plated bolts. These bolts are essential for various applications across multiple industries, including construction, automotive, and general engineering. This article explores the significance of zinc plated bolts, their advantages, the manufacturing process, and the role of manufacturers in ensuring high-quality products.

Understanding Zinc Plating

Zinc plating, or galvanization, is a process that involves the application of a thin layer of zinc to iron or steel surfaces. This coating provides a sacrificial barrier that protects the underlying metal from corrosion. In many applications where fasteners are exposed to moisture or corrosive environments, zinc plated bolts serve as an effective defense against rust and degradation.

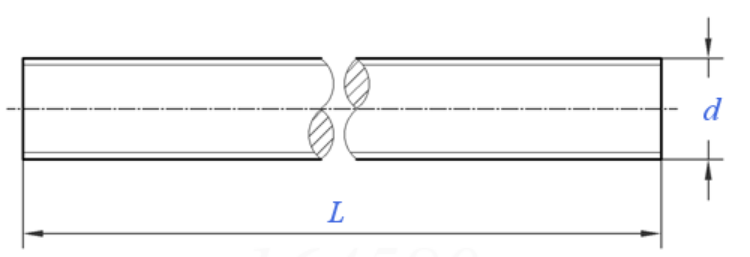

The plating process typically involves electroplating or hot-dip galvanizing. In electroplating, the fasteners are submerged in a solution containing zinc, and an electric current is used to deposit the zinc onto the surface. In contrast, hot-dip galvanizing involves immersing the bolts in molten zinc. Both methods yield robust protection, but hot-dip galvanizing offers a thicker coating, making it suitable for more demanding environments.

Advantages of Zinc Plated Bolts

Zinc plated bolts come with a host of advantages that make them a preferred choice for manufacturers and builders alike

1. Corrosion Resistance The primary benefit of zinc plating is its ability to prevent rust and oxidation. For projects exposed to moisture, such as outdoor structures or in marine environments, zinc plated bolts ensure longevity and reduce maintenance costs.

3. Cost-Effectiveness Compared to stainless steel, zinc plated bolts offer a more affordable option without significantly compromising on quality or durability.

zinc plated bolts manufacturer

4. Versatility These fasteners are available in various sizes and grades, making them suitable for diverse applications ranging from light-duty to heavy-duty use.

5. Improved Threading Zinc plating aids in reducing friction during installation, making it easier to screw or bolt components together.

The Manufacturing Process

The manufacturing of zinc plated bolts involves several critical steps. Initially, the raw materials, typically steel, undergo a thorough cleaning process to remove oils, dirt, and rust. This is essential for ensuring proper adhesion of the zinc coating. Next, the cleaned bolts are either electroplated or hot-dip galvanized, depending on the desired thickness of the zinc layer.

After the plating process, the bolts are inspected for quality assurance. This may involve checking for uniformity in coating thickness, adherence of the zinc layer, and overall appearance. Manufacturers often adhere to strict industry standards and certifications, such as ISO, to ensure their products meet specific safety and performance criteria.

The Role of Manufacturers

Manufacturers of zinc plated bolts play a vital role in the production chain. Not only do they ensure that the bolts are made from high-quality materials, but they also invest in advanced technology and processes to enhance efficiency and precision in production. Furthermore, reputable manufacturers provide detailed specifications and certifications, enabling customers to choose the right bolt for their specific application.

In addition, many manufacturers prioritize environmental sustainability by minimizing waste and using eco-friendly practices in their operations. This aligns with the growing demand for responsible manufacturing in today’s market.

Conclusion

Zinc plated bolts are an invaluable component in the toolkit of modern manufacturing. Their corrosion resistance, aesthetic appeal, cost-effectiveness, and versatility make them essential for various industries. As the demand for high-quality fastening solutions continues to rise, zinc plated bolt manufacturers are at the forefront, ensuring that these critical components meet the high standards required for durability and performance. By understanding the importance of these fasteners and their manufacturing processes, industries can make informed decisions, contributing to the overall success of their projects.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025