wheel cylinder bolt manufacturing processes and factory operations analysis

Oct . 18, 2024 12:11 Back to list

wheel cylinder bolt manufacturing processes and factory operations analysis

Understanding Wheel Cylinder Bolts A Look into Manufacturing and Quality Control

Wheel cylinders play a critical role in the hydraulic brake system of vehicles, ensuring effective braking performance. They are primarily used in drum brakes and consist of various components, among which the wheel cylinder bolts are essential for securing the cylinder in place. This article delves into the manufacturing processes involved in the production of wheel cylinder bolts, the importance of quality control in factories, and the technological advancements shaping the industry.

The Role of Wheel Cylinder Bolts

Wheel cylinder bolts perform a vital function in maintaining the structural integrity of the wheel cylinder assembly. These bolts must withstand significant amounts of pressure and vibration while ensuring that the braking system operates smoothly. Consequently, they must be made from high-strength materials and undergo rigorous testing to meet safety standards.

Manufacturing Processes

The manufacturing of wheel cylinder bolts typically involves several stages

1. Material Selection The first step is selecting the appropriate material. High-strength steel alloys are often used for their durability and corrosion resistance. Some manufacturers may also consider using stainless steel for specific applications, especially in environments prone to moisture and salt exposure.

2. Forging The selected material is then forged to ensure that the bolts attain the desired shape and strength. Forging involves heating the metal until malleable and then shaping it under immense pressure. This process aligns the grain structure of the metal, increasing its tensile strength.

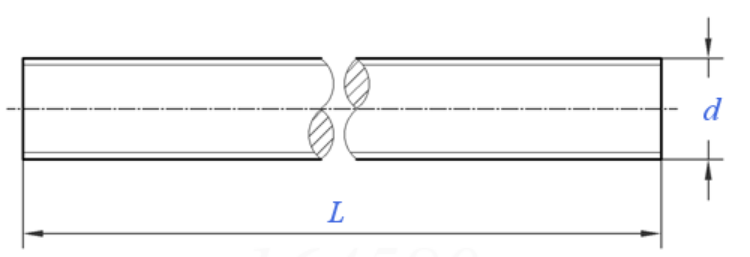

3. Machining After forging, the bolts undergo machining processes such as turning, milling, and drilling to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are commonly used for this purpose, allowing for high accuracy and repeatability in bolt production.

4. Heat Treatment Heat treatment is a critical step that enhances the mechanical properties of the bolts. Processes such as quenching and tempering are employed to improve hardness and ductility, ensuring the bolts can endure the harsh conditions they will face in service.

5. Surface Finishing The final bolts must have a smooth surface to prevent corrosion and ensure a proper seal. Techniques such as electroplating, anodizing, or powder coating may be applied based on the specific requirements of the application.

wheel cylinder bolts factories

Quality Control Measures

Quality control is paramount in ensuring that the wheel cylinder bolts meet stringent safety and performance standards. Factories implement various quality control measures throughout the manufacturing process, including

- Incoming Material Inspection All raw materials are subjected to tests for quality and specification compliance before being used in production.

- In-Process Inspection During manufacturing, various checkpoints are established where dimensional checks, surface evaluations, and mechanical property tests are performed. This monitoring helps catch any defects early in the production process.

- Final Testing Once the bolts are finished, they undergo rigorous testing to assess their strength, durability, and resistance to fatigue. Tests such as tensile strength assessments and stress tests simulate real-world conditions to evaluate performance.

- Certification and Compliance Adhering to international standards (such as ISO and ASTM) is crucial. Factories must certify their products through third-party audits, ensuring they meet the necessary regulatory requirements for safety.

Technological Advancements

Recent advancements in manufacturing technology are leading to improvements in the production of wheel cylinder bolts. Automation and robotics streamline many manufacturing processes, reducing human error and increasing efficiency. Additionally, the implementation of smart manufacturing techniques and Industry 4.0 initiatives allows for real-time monitoring and data collection, enhancing quality control measures.

Moreover, advancements in material science are paving the way for new alloy compositions that can offer better performance under extreme conditions. Research in nanotechnology and surface engineering is also contributing to the development of corrosion-resistant and high-strength coatings, further extending the lifespan of wheel cylinder bolts.

Conclusion

Wheel cylinder bolts are essential components that ensure the safety and reliability of vehicle braking systems. Their manufacturing requires a meticulous process, encompassing material selection, forging, machining, heat treatment, and surface finishing. With stringent quality control measures in place and ongoing technological advancements, factories are better equipped than ever to produce bolts that meet the high standards of the automotive industry. Properly manufactured and quality-certified wheel cylinder bolts contribute to safer vehicles and improved road safety for everyone.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025