Top Suppliers of 3mm Shim Washers for Industrial Applications and Custom Solutions

Aug . 01, 2024 06:06 Back to list

Top Suppliers of 3mm Shim Washers for Industrial Applications and Custom Solutions

The Role of 3mm Shim Washers in Various Industries A Focus on Top Companies

Shim washers, especially those measuring 3mm, play an essential role in various mechanical and engineering applications. These small but critical components serve to provide spacing, support, and stability in assemblies, preventing wear and tear while enhancing the efficiency of machines. With the growing demand for precision and quality in manufacturing, numerous companies are specializing in the production and supply of 3mm shim washers. This article will explore their functions, applications, and the leading companies in this domain.

Understanding Shim Washers

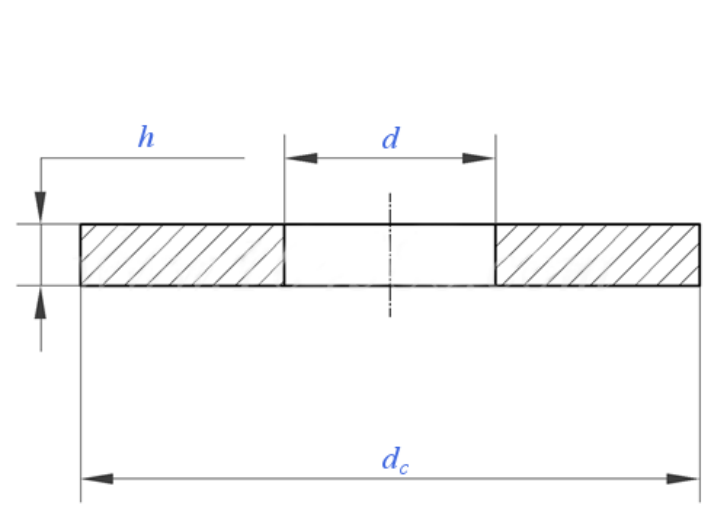

Shim washers are flat disks that can vary in thickness and diameter, functioning primarily to fill gaps between parts and align them properly. The 3mm size is particularly popular due to its versatility, making it suitable for different applications where precise spacing is required. These washers are often manufactured from materials such as stainless steel, plastic, rubber, and aluminum, depending on the application’s requirements for strength, flexibility, and resistance to corrosion.

Applications Across Industries

1. Automotive Industry In the automotive sector, 3mm shim washers are crucial for achieving the precise spacing required for various components, such as engine parts, suspension systems, and brake assemblies. They help in minimizing vibrations and reducing wear, leading to improved vehicle performance and longevity.

2. Aerospace Applications The aerospace industry demands the highest standards of precision. 3mm shim washers are employed in aircraft assemblies to ensure the secure fit of components, enhancing safety and performance. Their ability to withstand extreme conditions makes them indispensable in this sector.

3. Manufacturing and Machinery In manufacturing, shim washers are ubiquitous, used in machinery assembly, industrial equipment, and tooling. They assist in leveling structures and machines, ensuring proper operation and decreasing the likelihood of mechanical failure.

4. Electronics Industry The electronics sector utilizes 3mm shim washers to secure components on circuit boards and within electronic devices. Their lightweight and non-conductive nature help in maintaining the integrity of electronic circuits.

3mm shim washers companies

Leading Companies in the Shim Washer Market

Several companies have established themselves as leaders in the production of 3mm shim washers, providing high-quality products to meet diverse industry needs. Here are a few noteworthy names

- Fastenal Known for its extensive inventory of fasteners and industrial supplies, Fastenal offers a wide range of shim washers, including 3mm options. Their commitment to quality and customer service makes them a preferred supplier for many industries.

- McMaster-Carr McMaster-Carr is renowned for its vast selection of industrial products. They provide customizable shim washers in various materials, thicknesses, and diameters, including the sought-after 3mm size, catering to specific customer requirements.

- Grainger A leading supplier of maintenance, repair, and operating (MRO) products, Grainger stocks a variety of shim washers. Their easy-to-navigate online platform and quick shipping services make them a go-to choice for engineers and procurement specialists.

- Spahn & Rose Lumber Co. While primarily focused on the lumber industry, Spahn & Rose also offers hardware components, including shim washers. Their comprehensive approach to customer needs makes them a trusted ally in both construction and manufacturing.

Conclusion

3mm shim washers may seem like minor components in the grand scheme of industrial applications, but their significance cannot be understated. With a variety of companies manufacturing these essential parts, businesses can find the right size, material, and specifications to meet their needs. As industries continue to prioritize precision and reliability, the demand for high-quality shim washers will only grow, driving innovation and improvement among leading manufacturers. Organizations looking to enhance their operations should carefully consider the selection of shim washers as an integral part of their assembly and maintenance processes.

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025