Top Manufacturers of Self-Drilling Screws Made from High-Quality Carbon Steel for Various Applications

Jul . 29, 2024 05:39 Back to list

Top Manufacturers of Self-Drilling Screws Made from High-Quality Carbon Steel for Various Applications

Understanding Carbon Steel Self-Drilling Screws Manufacturers and Their Importance

In the world of construction and manufacturing, the choice of fasteners is critical to ensuring the integrity and durability of structures. Among various fastening solutions available in the market, self-drilling screws made from carbon steel have gained significant popularity. These screws are not only efficient but also provide a strong hold, making them ideal for a variety of applications. This article explores the characteristics of carbon steel self-drilling screws and the key role played by manufacturers in the industry.

What are Carbon Steel Self-Drilling Screws?

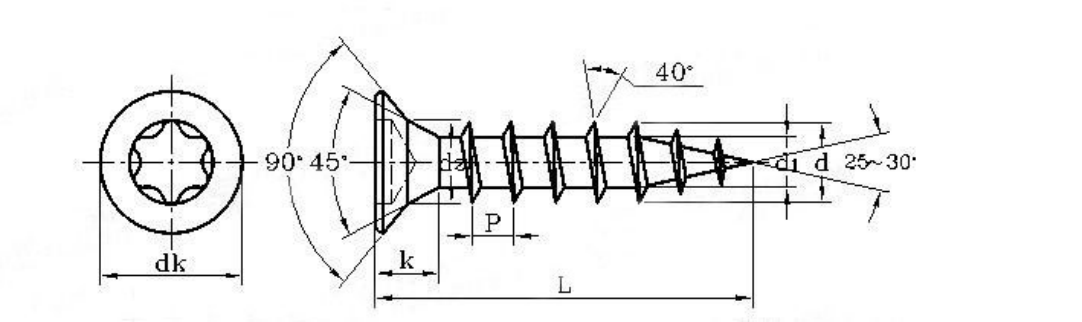

Carbon steel self-drilling screws are specialized fasteners designed for drilling through materials such as metal, wood, and plastic without the need for a pre-drilled pilot hole. The unique design of these screws features a drill point at the tip, which allows them to cut through material as they are driven in. This innovation saves time and labor costs, making them a preferred choice for both DIY enthusiasts and professional contractors.

The manufacturing of self-drilling screws from carbon steel is a deliberate choice due to the material’s strength and durability. Carbon steel is known for its hardness and ability to withstand significant loads and stresses. Additionally, manufacturers often coat these screws with protective layers to enhance their resistance to corrosion, further extending their lifespan and performance in various environments.

The Role of Manufacturers

carbon steel self drilling screws manufacturers

The importance of manufacturers in the production of carbon steel self-drilling screws cannot be overstated. They are responsible for ensuring that the screws meet the highest quality standards, making them reliable for critical applications. Manufacturers engage in extensive research and development to innovate and improve the performance of self-drilling screws, including optimizing their design for specific tasks.

One of the primary considerations for manufacturers is the quality of the raw materials used. Sourcing high-quality carbon steel is essential, as the chemical composition directly affects the strength and performance of the finished screws. Additionally, manufacturers invest in advanced machinery and technology to enhance the precision and efficiency of the production process.

Quality control is another critical aspect of the manufacturing process. Reputable manufacturers implement rigorous testing protocols to ensure that each batch of screws meets established performance criteria. This includes tensile strength tests, corrosion resistance assessments, and drilling tests to validate the efficiency of the screws in real-world applications.

Furthermore, manufacturers often provide a range of specifications and custom solutions to meet the diverse needs of clients. This might include variations in screw length, diameter, head style, and thread design to suit different materials and project requirements. As a result, builders and contractors can confidently select the right fasteners tailored to their specific tasks, whether constructing a metal framework, roofing, or woodworking projects.

Conclusion

Carbon steel self-drilling screws play a vital role in modern construction and manufacturing. With their efficiency, strength, and ease of use, they are indispensable for a variety of applications. The manufacturers of these fasteners are essential in ensuring quality, innovation, and reliability, ultimately impacting the success of construction projects. As the demand for robust fastening solutions continues to grow, the role of these manufacturers will remain crucial in providing high-quality products that meet the industry’s evolving needs. Whether you are a contractor or an amateur DIYer, understanding the advantages of carbon steel self-drilling screws can significantly enhance the outcome of your projects.

Latest news

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025

-

Premium Cabinet Bolts Supplier - Quality & Wholesale Fasteners

NewsAug.09,2025

-

Reliable Cabinet Bolts Supplier | Quality & Bulk Fasteners

NewsAug.07,2025