Top Manufacturers of HDG Stud Bolts for Reliable Construction and Industrial Applications

Jul . 31, 2024 22:07 Back to list

Top Manufacturers of HDG Stud Bolts for Reliable Construction and Industrial Applications

HDG Stud Bolt Manufacturers An Overview

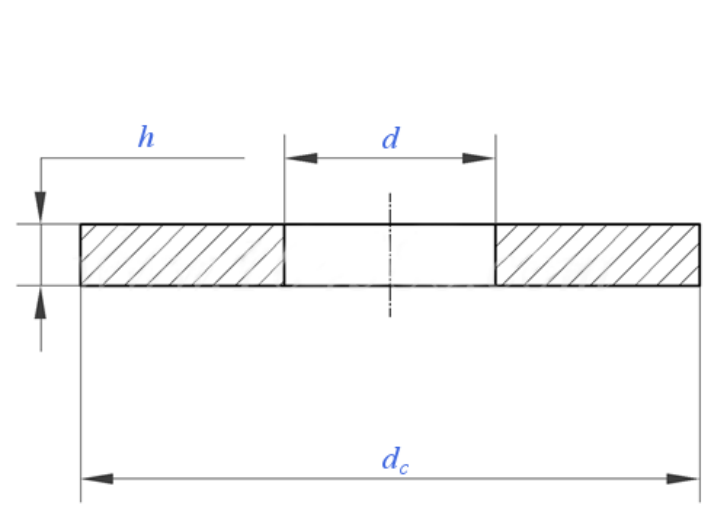

Hot-Dip Galvanized (HDG) stud bolts are essential components in various industries, known for their strength, durability, and resistance to corrosion. These bolts, typically constructed from high-strength carbon steel and then coated with zinc through the hot-dip galvanization process, serve crucial roles in construction, automotive, marine, and other applications where robust fastening solutions are required.

The Importance of HDG Stud Bolts

The significance of HDG stud bolts cannot be overstated. One of the main advantages of using HDG products is their exceptional corrosion resistance. The hot-dip galvanization process involves immersing the steel in molten zinc, creating a thick protective layer that serves as a barrier against environmental factors such as moisture and chemicals. This makes HDG stud bolts particularly suitable for outdoor applications and environments with high levels of humidity or exposure to corrosive substances.

Moreover, HDG stud bolts maintain their strength even under extreme conditions. They are capable of handling significant loads and are often used in structural connections, which highlights their reliability. Industries that often require HDG stud bolts include construction, where they are used in steel structures, bridges, and other heavy-duty applications. In the automotive sector, they are essential for securing various components, ensuring both performance and safety.

Choosing the Right Manufacturer

When it comes to sourcing HDG stud bolts, selecting the right manufacturer is crucial. The quality of the bolts can have a direct impact on the longevity and safety of the application in which they are used. Here are a few key factors to consider when choosing a manufacturer

1. Quality Assurance Reputable manufacturers should adhere to international quality standards, such as ISO 9001. Certification indicates that the manufacturer has implemented a quality management system, ensuring consistency in production and upholding high standards.

hdg stud bolt manufacturers

2. Experience and Expertise Manufacturers with years of experience in the industry often have a better understanding of the technical requirements and challenges associated with the production of HDG stud bolts. Expertise in metallurgical processes and galvanization can also enhance product quality.

3. Product Range A reliable manufacturer should offer a variety of stud bolts and customization options. Different applications may require specific dimensions, thread types, or coatings. A diverse product range ensures that customers can find the right solution for their needs.

4. Customer Support Good communication and customer service are essential. Manufacturers should provide assistance throughout the ordering process and be available to address any post-purchase inquiries. This includes clear documentation regarding product specifications and certifications.

5. Sustainability Practices In today’s eco-conscious market, manufacturers that engage in sustainable practices stand out. This includes using environmentally friendly materials, efficient production processes, and responsible waste management.

Notable Manufacturers

Several notable manufacturers are recognized for their expertise in HDG stud bolt production. Companies like Fastenal, Bolt Products, and Birmingham Fastener have established themselves as leaders in this field, providing high-quality products that meet various industry standards. Their commitment to innovation and customer service has allowed them to build long-term relationships within the industry.

Conclusion

In conclusion, HDG stud bolts play a vital role across multiple sectors due to their strength and corrosion resistance. Selecting the right manufacturer is critical to ensure product quality and reliability. By focusing on quality assurance, experience, product range, customer support, and sustainability, industries can find the best solutions to meet their fastening needs. As technology advances, the future of HDG stud bolts looks promising, with continuous improvements in production techniques and materials further enhancing their applications in versatile industries.

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025