Top GB Thread Rods Producers Exploring Leading Manufacturers

Jun . 26, 2024 09:54 Back to list

Top GB Thread Rods Producers Exploring Leading Manufacturers

GB Thread Rods An In-depth Look into the Manufacturers

Global standards play a pivotal role in ensuring quality and consistency across industries, and when it comes to threaded rods, the Chinese National Standard (GB) is a benchmark for excellence. GB thread rods, also known as Chinese Standard Threaded Rods, are widely utilized in construction, machinery, and engineering sectors due to their precision, durability, and strength. This article delves into the world of GB thread rod manufacturers, exploring their significance, production processes, and the impact they have on global markets.

GB thread rods are manufactured by a myriad of companies in China, each adhering to strict guidelines set forth by the standard. These manufacturers specialize in producing high-quality steel rods with precise threading, designed to withstand heavy loads and extreme conditions. The manufacturing process involves several stages, including material selection, forging, heat treatment, threading, and quality control.

The first step in manufacturing GB thread rods is selecting the right raw materials. High-grade steel, such as carbon steel or alloy steel, is commonly used to ensure robustness and resistance to corrosion. The selected steel is then forged, a process that involves heating the metal to a high temperature and shaping it into the desired form. This step is crucial for enhancing the material's mechanical properties.

Following forging, the rods undergo heat treatment, which can include quenching and tempering. This process strengthens the metal, increasing its hardness and toughness. The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications

The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications gb thread rods manufacturers. This ensures compatibility with nuts and other mating parts.

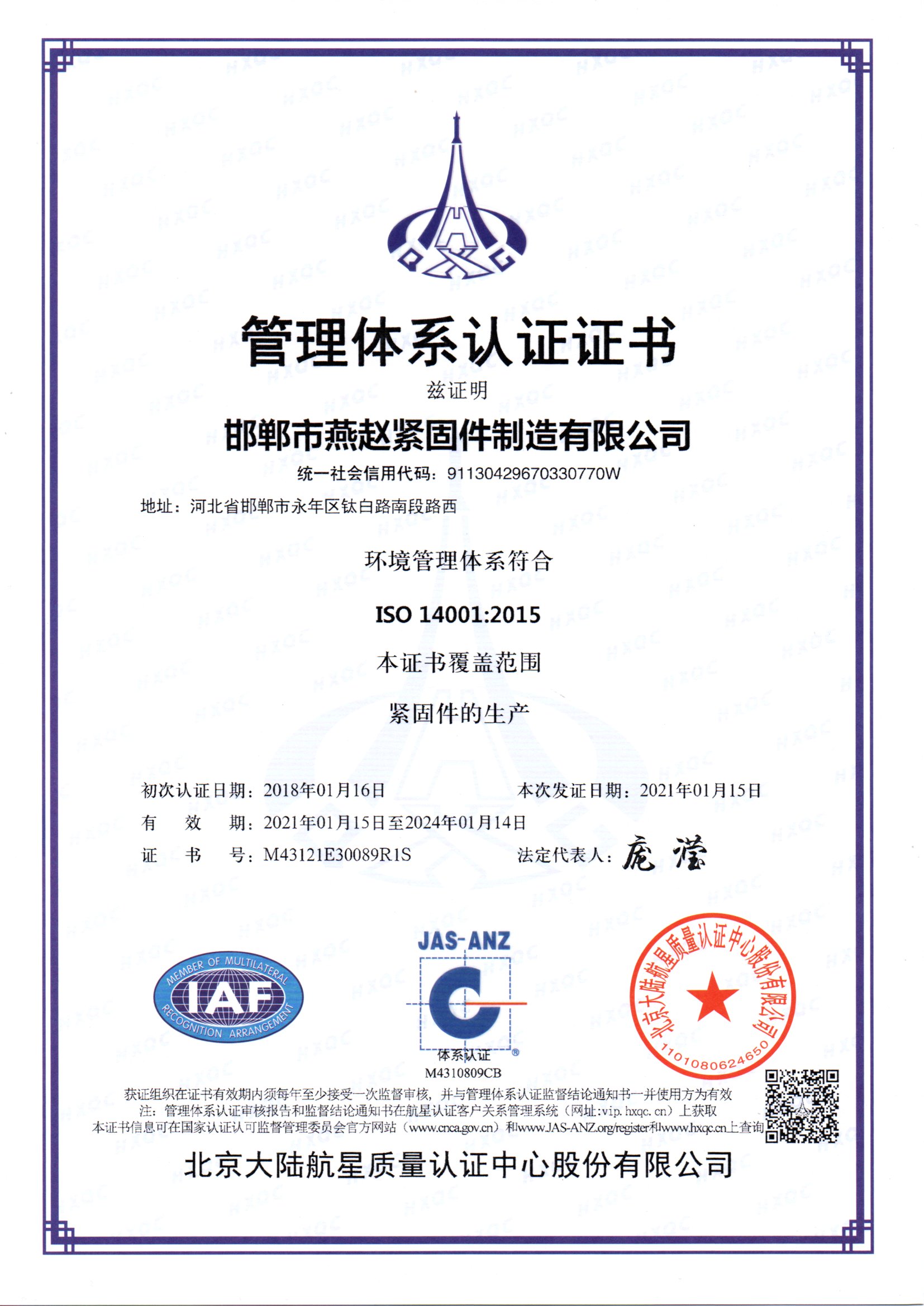

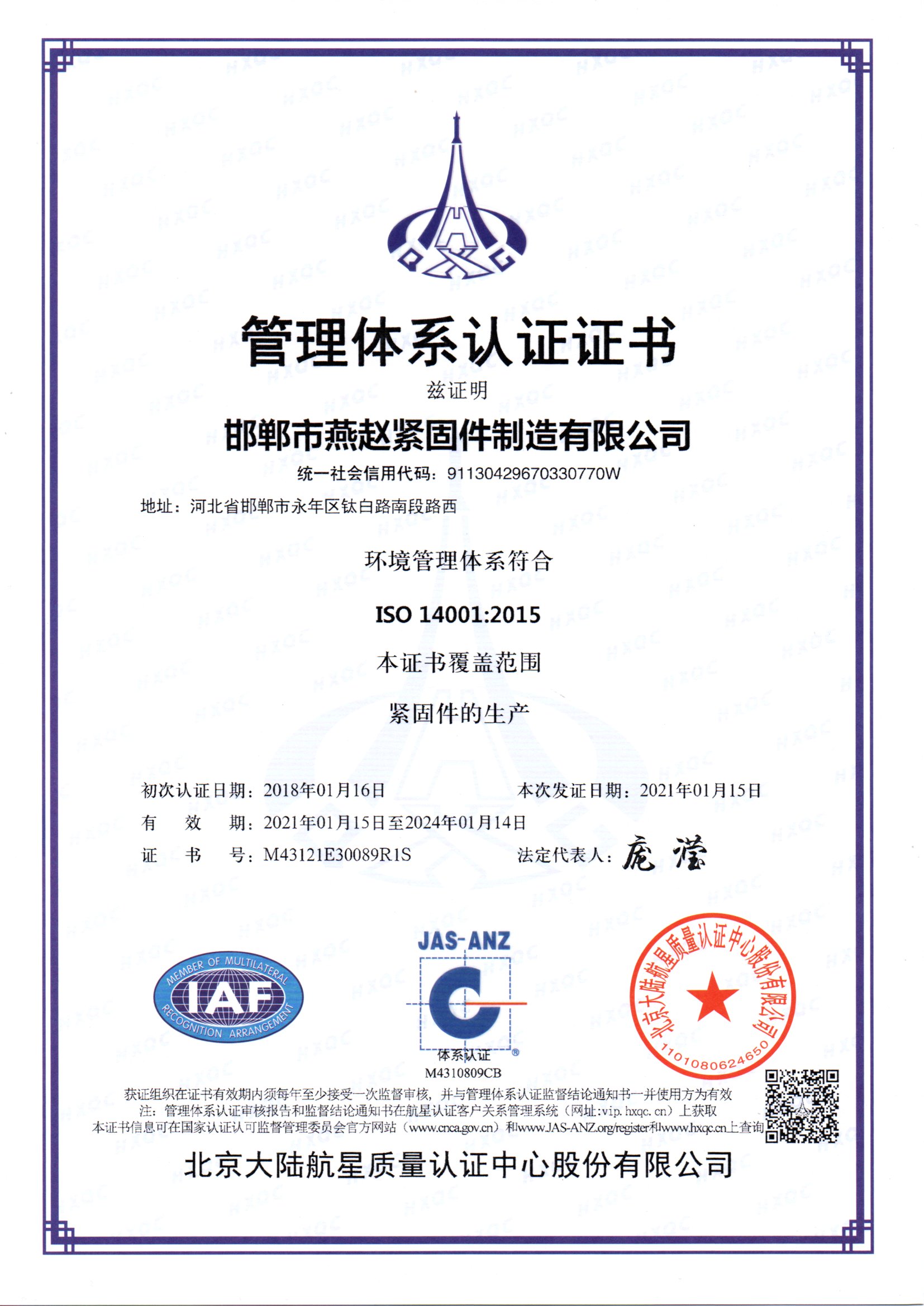

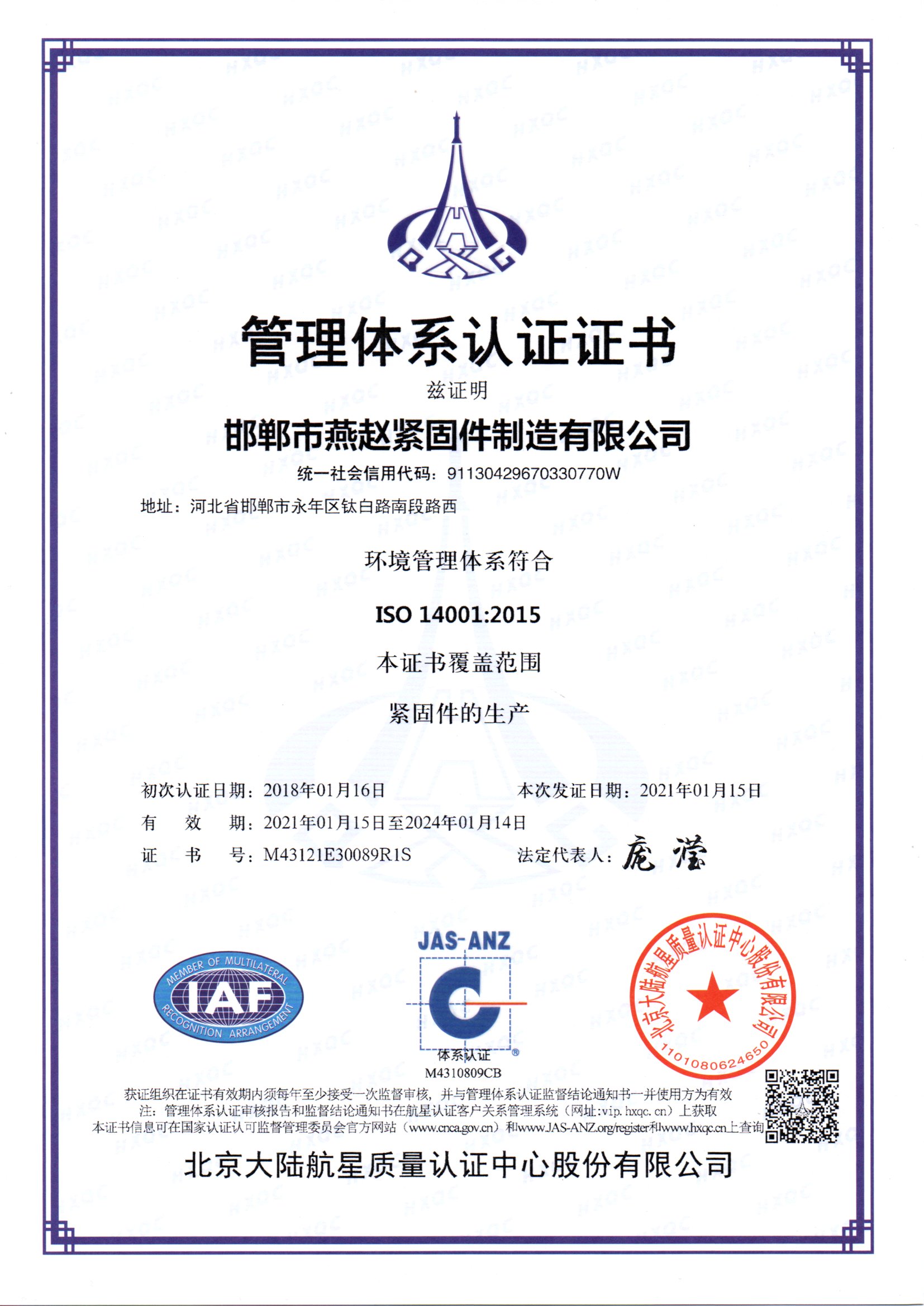

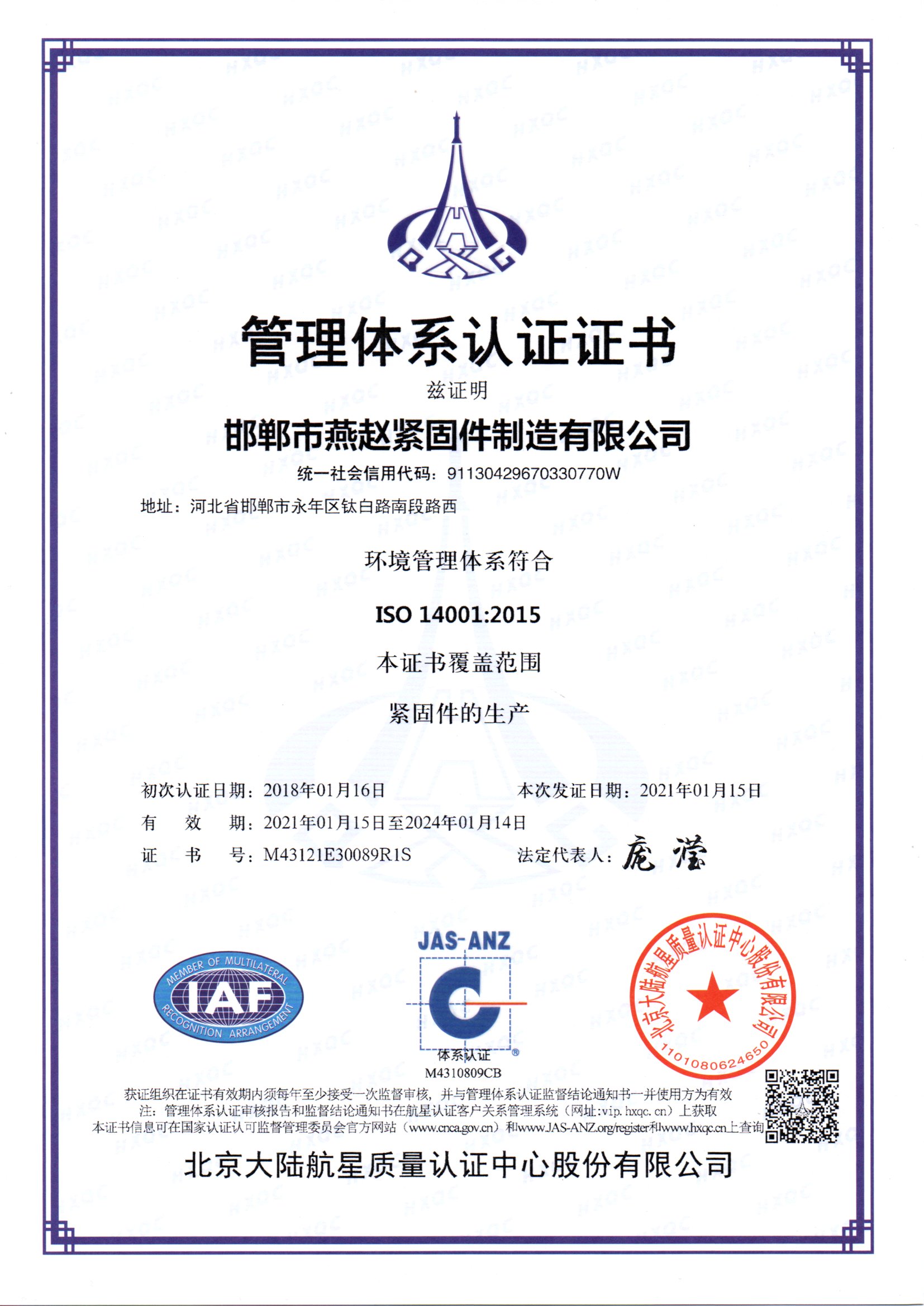

Quality control is an integral part of the manufacturing process. GB thread rod manufacturers conduct rigorous tests to verify the rod's dimensions, tensile strength, and thread quality. These checks guarantee that the final product meets the stringent GB standards, ensuring customer satisfaction and safety in various applications.

Chinese GB thread rod manufacturers have made significant strides in global markets due to their competitive pricing, efficient production capabilities, and adherence to international standards. Their products find use in diverse projects, from civil engineering structures like bridges and buildings to industrial machinery and equipment assembly. The reliability and affordability of GB thread rods have contributed to their popularity among contractors, engineers, and suppliers worldwide.

In conclusion, GB thread rod manufacturers play a vital role in the global supply chain, providing high-quality threaded rods that adhere to rigorous standards. Their commitment to precision, durability, and safety has solidified their position in the industry. As technology advances and sustainability becomes a greater concern, these manufacturers continue to innovate, striving for even higher efficiency and eco-friendly practices while maintaining the integrity of the GB standard.

gb thread rods manufacturers. This ensures compatibility with nuts and other mating parts.

Quality control is an integral part of the manufacturing process. GB thread rod manufacturers conduct rigorous tests to verify the rod's dimensions, tensile strength, and thread quality. These checks guarantee that the final product meets the stringent GB standards, ensuring customer satisfaction and safety in various applications.

Chinese GB thread rod manufacturers have made significant strides in global markets due to their competitive pricing, efficient production capabilities, and adherence to international standards. Their products find use in diverse projects, from civil engineering structures like bridges and buildings to industrial machinery and equipment assembly. The reliability and affordability of GB thread rods have contributed to their popularity among contractors, engineers, and suppliers worldwide.

In conclusion, GB thread rod manufacturers play a vital role in the global supply chain, providing high-quality threaded rods that adhere to rigorous standards. Their commitment to precision, durability, and safety has solidified their position in the industry. As technology advances and sustainability becomes a greater concern, these manufacturers continue to innovate, striving for even higher efficiency and eco-friendly practices while maintaining the integrity of the GB standard.

The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications

The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications The next stage is threading, where the rod is cut or rolled to create the threads according to the GB specifications gb thread rods manufacturers. This ensures compatibility with nuts and other mating parts.

Quality control is an integral part of the manufacturing process. GB thread rod manufacturers conduct rigorous tests to verify the rod's dimensions, tensile strength, and thread quality. These checks guarantee that the final product meets the stringent GB standards, ensuring customer satisfaction and safety in various applications.

Chinese GB thread rod manufacturers have made significant strides in global markets due to their competitive pricing, efficient production capabilities, and adherence to international standards. Their products find use in diverse projects, from civil engineering structures like bridges and buildings to industrial machinery and equipment assembly. The reliability and affordability of GB thread rods have contributed to their popularity among contractors, engineers, and suppliers worldwide.

In conclusion, GB thread rod manufacturers play a vital role in the global supply chain, providing high-quality threaded rods that adhere to rigorous standards. Their commitment to precision, durability, and safety has solidified their position in the industry. As technology advances and sustainability becomes a greater concern, these manufacturers continue to innovate, striving for even higher efficiency and eco-friendly practices while maintaining the integrity of the GB standard.

gb thread rods manufacturers. This ensures compatibility with nuts and other mating parts.

Quality control is an integral part of the manufacturing process. GB thread rod manufacturers conduct rigorous tests to verify the rod's dimensions, tensile strength, and thread quality. These checks guarantee that the final product meets the stringent GB standards, ensuring customer satisfaction and safety in various applications.

Chinese GB thread rod manufacturers have made significant strides in global markets due to their competitive pricing, efficient production capabilities, and adherence to international standards. Their products find use in diverse projects, from civil engineering structures like bridges and buildings to industrial machinery and equipment assembly. The reliability and affordability of GB thread rods have contributed to their popularity among contractors, engineers, and suppliers worldwide.

In conclusion, GB thread rod manufacturers play a vital role in the global supply chain, providing high-quality threaded rods that adhere to rigorous standards. Their commitment to precision, durability, and safety has solidified their position in the industry. As technology advances and sustainability becomes a greater concern, these manufacturers continue to innovate, striving for even higher efficiency and eco-friendly practices while maintaining the integrity of the GB standard. Latest news

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025