tighten toilet bolts exporters

Nov . 02, 2024 06:08 Back to list

tighten toilet bolts exporters

Tightening Toilet Bolts A Guide for Exporters

Toilet installation may seem like a simple task, but it involves critical components that ensure the functionality and durability of restroom facilities. One important aspect often overlooked is the tightening of toilet bolts. For exporters dealing with sanitary ware, understanding the nuances of this process can enhance product quality and customer satisfaction.

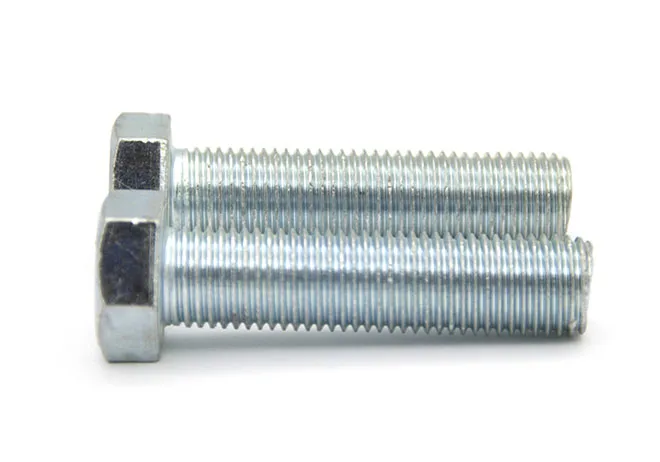

Toilet bolts serve as the anchor points that secure the toilet to the floor, ensuring stability and preventing leaks. Properly tightened bolts not only eliminate the risks of wobbling and shifting but also safeguard against potential water damage to both the toilet and surrounding areas. Given the important role of toilet bolts, exporters must be knowledgeable about the standards and practices related to their installation and maintenance.

Importance of Quality Components

As an exporter, it’s essential to source high-quality toilet bolts made from durable materials such as stainless steel or brass. These materials resist corrosion and wear, further extending the lifespan of toilets in various environments. When communicating with manufacturers, be sure to emphasize the importance of using quality materials, as it can significantly impact customer satisfaction and reduce return rates.

Installation Guidelines and Best Practices

For those dealing with toilet installations, it is crucial to follow proper guidelines regarding the tightening of toilet bolts. Here are some best practices

1. Initial Alignment Ensure that the toilet is properly aligned with the flange and that the wax ring is correctly placed. This initial setup is vital to prevent future leaks.

tighten toilet bolts exporters

2. Uniform Tightening When securing the bolts, apply an even pressure across all points to avoid warping the toilet base. Tighten the nuts progressively, switching between each side to achieve an equal distribution of pressure.

3. Torque Specifications Establishing torque specifications is essential for consistent results. Many manufacturers recommend using a torque wrench to ensure that bolts are tightened to the appropriate settings without overtightening, which can crack the porcelain.

4. Regular Maintenance Advise customers on the importance of periodic checks to ensure the bolts remain tight. Over time, the structural integrity of the flange and the wax seal can erode, necessitating adjustments.

Market Insights

Understanding regional practices around toilet bolt tightening can be beneficial for exporters. For instance, countries with high humidity or varying temperature fluctuations may experience different levels of settling and wear on installed toilets. Tailoring products and installation guidelines to meet these specific conditions can give exporters a competitive edge.

Conclusion

In conclusion, the proper installation and tightening of toilet bolts play a crucial role in the functionality of sanitary ware. As exporters, providing high-quality products and educating customers on best practices can significantly enhance the usability and durability of toilets. By focusing on quality components, adhering to installation guidelines, and considering regional practices, exporters can ensure greater satisfaction and build lasting relationships with clients in the worldwide market. Investing in these areas is not only beneficial for the immediate sale but also contributes to the long-term reputation and success of the exporting business.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025