threshold screws factories

Nov . 19, 2024 08:42 Back to list

threshold screws factories

The Impact of Threshold Screws Factories on Modern Manufacturing

In today’s fast-paced manufacturing environment, the efficiency and effectiveness of production processes are crucial for meeting market demands. One key component that underpins many industrial applications is the screw. Among the various types of screws, threshold screws have gained significant attention due to their unique design and functional advantages. The emergence of specialized factories dedicated to the production of threshold screws has transformed the landscape of manufacturing by ensuring quality, precision, and reliability.

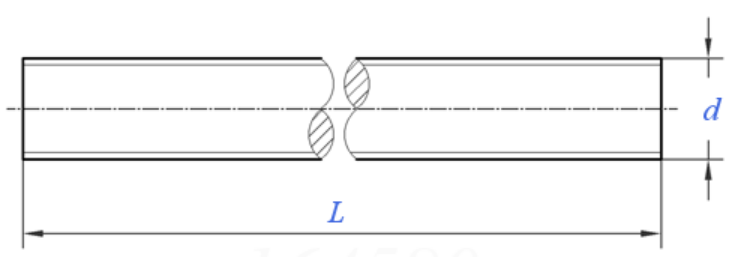

Threshold screws are specifically designed to serve as anchoring points, providing stability and support in various applications, from construction to automotive assembly. The unique features of threshold screws, such as their robust design and ability to withstand significant stress, make them essential in critical applications. The demand for high-quality threshold screws has prompted the establishment of specialized factories that focus exclusively on their production, resulting in improved manufacturing processes and outcomes.

The Impact of Threshold Screws Factories on Modern Manufacturing

One of the primary advantages of threshold screw factories is their ability to leverage advanced technologies. Modern manufacturing relies heavily on automation and robotics to enhance precision and reduce human error. Factories producing threshold screws often employ CNC (Computer Numerical Control) machines, which allow for the intricate shaping and threading of screws with exceptional precision. This technological integration not only accelerates production rates but also significantly improves the quality of the finished product.

threshold screws factories

Moreover, these factories typically emphasize research and development (R&D) to innovate new designs and materials for threshold screws. Advances in metallurgy and materials science have led to the development of stronger, lighter, and more corrosion-resistant screws. By investing in R&D, threshold screw manufacturers can create products that not only meet current standards but also anticipate future market demands, thus positioning themselves as industry leaders.

Environmental sustainability is another critical consideration in modern manufacturing, including the production of threshold screws. Many factories are now adopting eco-friendly practices, such as recycling waste materials and using energy-efficient machinery. The implementation of sustainable practices not only reduces the carbon footprint of the manufacturing process but also appeals to environmentally conscious consumers and businesses. As a result, threshold screw factories are increasingly viewed as models of sustainability within the industry.

Quality control is paramount in the production of threshold screws due to their pivotal role in various applications. Factories producing these screws often employ rigorous testing protocols to ensure each product meets or exceeds industry standards. This commitment to quality assurance helps manufacturers avoid costly recalls and enhances their reputation in the marketplace. Consequently, clients can rest assured that they are using reliable components that will not compromise the integrity of their projects.

The growing network of threshold screw factories also facilitates collaboration within the manufacturing ecosystem. By specializing in this niche, these factories often become key suppliers for larger manufacturers in sectors such as construction, automotive, and electronics. This interconnectivity fosters a more resilient supply chain, where companies can rely on each other to provide high-quality components promptly. As businesses continue to navigate the challenges of a globalized economy, such synergies will be increasingly important.

In conclusion, threshold screws factories play a critical role in modern manufacturing by producing high-quality, reliable components essential for various applications. Through the adoption of advanced technologies, a commitment to sustainability, and a focus on quality control, these factories are not only enhancing their own productivity but also contributing to the overall efficiency of the manufacturing sector. As industries evolve, the significance of specialized production facilities like those for threshold screws will only continue to grow, highlighting their importance in the quest for innovation and excellence in manufacturing.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025