threaded rod and stud bolt manufacturer

Nov . 15, 2024 08:44 Back to list

threaded rod and stud bolt manufacturer

Understanding Threaded Rods and Stud Bolts A Comprehensive Overview

In the realm of manufacturing and construction, fasteners play a critical role in assembling components and securing structures. Among the various types of fasteners, threaded rods and stud bolts stand out due to their versatility and strength. This article aims to provide insights into these essential components, highlighting their applications, advantages, and differences, while also delving into the manufacturing processes involved.

What are Threaded Rods and Stud Bolts?

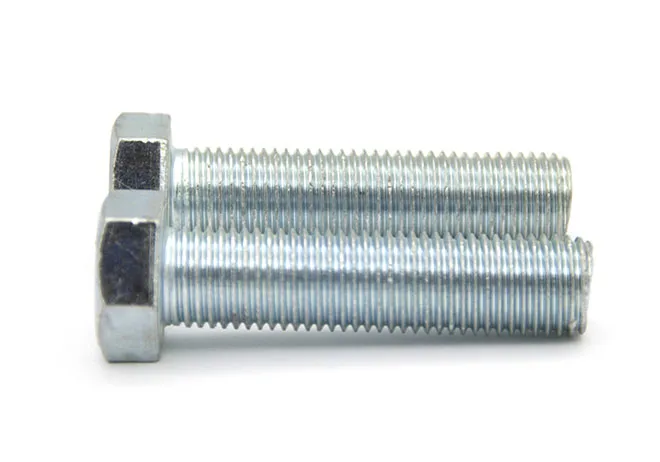

Threaded rods are long, cylindrical rods that are fully threaded along their length. They are typically made from materials like stainless steel, carbon steel, or other alloys, providing strength and resistance to corrosion and wear. These rods serve various purposes, such as serving as anchors or connectors in construction and industrial applications.

Stud bolts, on the other hand, are fasteners that feature threads on both ends and a smooth shank in between. They are often used in conjunction with nuts to secure parts together. Stud bolts are designed for high-strength applications, such as in flanged connections in piping systems and other heavy machinery.

Applications of Threaded Rods and Stud Bolts

Both threaded rods and stud bolts are used across various industries, including construction, automotive, aerospace, and machinery.

1. Construction In construction, threaded rods serve as tension devices, while stud bolts are commonly used in securing steel structures. They provide the necessary tensile strength required for heavy loads and dynamic stresses.

2. Automotive In automotive applications, stud bolts are crucial for engine assembly, axle connections, and securing components like cylinder heads. They assist in maintaining the integrity and safety of the vehicle.

3. Aerospace The aerospace industry relies on high-strength stud bolts to join critical parts that endure extreme conditions. The reliability and precision of these fasteners are vital for the overall performance of aircraft.

4. Machinery In machinery, both types of fasteners are used to maintain stability and strength in assembly, ensuring the machinery operates efficiently under various loads.

Advantages of Threaded Rods and Stud Bolts

The choice of threaded rods and stud bolts offers several advantages

threaded rod and stud bolt manufacturer

- Strength and Durability Both components are designed to withstand significant loads and stresses, making them ideal for heavy-duty applications.

- Versatility They can be used in a multitude of applications, across different industries, making them a go-to solution for many engineering challenges.

- Customizability Manufacturers can customize length, diameter, and material to meet specific requirements, providing tailored solutions for various projects.

- Ease of Installation Their design allows for straightforward installation, often requiring basic tools and methods, which inherently reduces labor costs and time.

Manufacturing Process

The manufacturing of threaded rods and stud bolts follows strict quality standards to ensure their performance and longevity.

1. Material Selection It begins with the selection of high-quality raw materials, often subjected to stringent tests for strength and corrosion resistance.

2. Machining The raw materials are then cut to the desired lengths, followed by machining to create the necessary threads. This can include processes such as turning, milling, and grinding.

3. Heat Treatment In many cases, heat treatment processes are applied to enhance the strength and durability of the fasteners.

4. Finishing Finally, finishing processes such as plating, coating, or polishing may be applied to improve corrosion resistance and aesthetics.

5. Quality Control Rigorous testing and inspection are conducted to ensure each product meets the specified standards.

Conclusion

In summary, threaded rods and stud bolts are vital components in various industries, providing strength, versatility, and reliability. Their manufacturing involves meticulous processes and quality control, ensuring they perform effectively across applications. As industries continue to evolve, the demand for high-quality fasteners will remain significant, underlining the importance of threaded rods and stud bolts in modern engineering and construction.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025