Supplier of High-Quality Titanium Nuts and Bolts for Industrial Applications

Aug . 20, 2024 17:30 Back to list

Supplier of High-Quality Titanium Nuts and Bolts for Industrial Applications

The Importance of Titanium Nuts and Bolts in Modern Engineering

In the ever-evolving landscape of engineering and manufacturing, the demand for high-performance materials has never been greater. Among these, titanium stands out as a premier choice for nuts and bolts, thanks to its unique combination of strength, lightweight properties, and corrosion resistance. Suppliers of titanium nuts and bolts play a crucial role in industries ranging from aerospace to medical devices, ensuring that the components meet stringent standards and specifications.

What Makes Titanium Unique?

Titanium is known for its remarkable strength-to-weight ratio, making it ideal for applications where minimizing weight is essential without sacrificing strength. It is approximately 45% lighter than steel while providing comparable strength, which is critical in sectors such as aerospace, where reducing weight can significantly enhance fuel efficiency and performance. Additionally, titanium's excellent corrosion resistance means that it can withstand harsh environments, including extreme temperatures and exposure to chemicals. This durability extends the lifespan of components, reducing the need for frequent replacements and maintenance.

Applications of Titanium Nuts and Bolts

1. Aerospace Industry In aerospace manufacturing, titanium nuts and bolts are used extensively in aircraft structures, engines, and landing gear. The lightweight and strength of titanium contribute to improved fuel efficiency and increased payload capacity, making it a vital material in aircraft design.

2. Automotive Sector The automotive industry is increasingly adopting titanium fasteners for high-performance vehicles. Titanium components help in reducing the overall weight of the vehicle while enhancing performance and safety. This is particularly important in sports cars and racing applications, where performance optimization is a key focus.

3. Medical Devices In the medical field, titanium is preferred for implants and surgical instruments due to its biocompatibility, strength, and resistance to corrosion. Titanium nuts and bolts are used in various medical devices, ensuring they remain functional and safe within the human body.

4. Marine Applications The marine industry benefits from titanium's corrosion resistance, which is essential for components subjected to saltwater and other corrosive environments. Titanium nuts and bolts are commonly used in shipbuilding and offshore constructions.

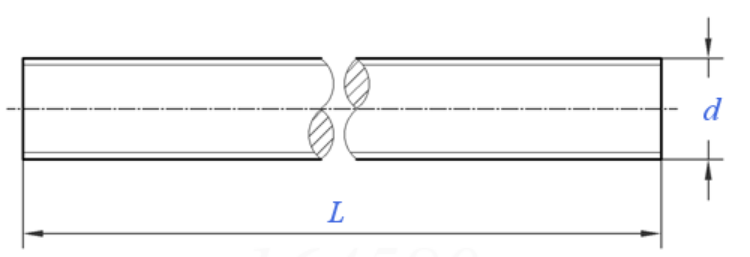

titanium nuts and bolts supplier

Choosing a Titanium Nuts and Bolts Supplier

When selecting a supplier for titanium nuts and bolts, several factors should be considered

- Quality Assurance Ensuring that the supplier has certifications and quality control measures in place is essential. Look for suppliers that comply with international standards, such as ISO 9001.

- Material Certification Verify that the titanium used in the nuts and bolts is certified and complies with industry standards. This ensures that the products are reliable and safe for their intended applications.

- Customization Options Different projects may require specific dimensions and threading. A good supplier should offer customization options to meet the unique needs of their clients.

- Technical Support A supplier should provide technical support and guidance on the best materials and products for specific applications, especially in complex engineering projects.

Conclusion

Titanium nuts and bolts are invaluable components in modern engineering, providing a combination of strength, lightweight efficiency, and corrosion resistance. Suppliers of these vital fasteners enable industries to push the boundaries of what's possible, supporting innovations in aerospace, automotive, medical, and marine applications. As technology continues to advance, the role of titanium fasteners will only grow, making it imperative for companies to partner with reliable suppliers to enhance their projects' performance and durability. Investing in high-quality titanium nuts and bolts is not just a decision; it’s a step towards achieving excellence in engineering.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025