M20 Stud Bolt Prices and Manufacturers for Quality Fasteners

Oct . 18, 2024 22:30 Back to list

M20 Stud Bolt Prices and Manufacturers for Quality Fasteners

Understanding the Pricing Factors for M20 Stud Bolts in Factories

When it comes to industrial manufacturing, fastening solutions are critical. Among these, stud bolts play a vital role in ensuring the structural integrity of various products and machines. Particularly, M20 stud bolts have gained significant traction in several industries due to their robust performance and reliability. This article will delve into the pricing of M20 stud bolts from factories and the various factors that influence their costs.

What are M20 Stud Bolts?

M20 stud bolts are fasteners characterized by their metric size; specifically, M20 refers to the nominal diameter of the bolt, which measures 20 millimeters. These bolts are often used in applications where high strength is required. They are typically fastened with nuts at both ends and are made from various materials, including carbon steel, stainless steel, and alloy steel, depending on the application's requirements.

Key Factors Influencing the Price of M20 Stud Bolts

1. Material Composition The type of material used in manufacturing M20 stud bolts significantly impacts their price. Stainless steel, while offering corrosion resistance, tends to be pricier than standard carbon steel. Similarly, specialized alloys that are designed to withstand extreme conditions or chemicals will naturally incur higher production costs. Factories must source quality materials, which directly reflects in the final pricing.

2. Manufacturing Process The methods employed in the production of stud bolts can vary widely. Forged bolts are typically stronger and more durable than those made from cut or cast materials, but the forging process requires more energy and resources, thereby increasing costs. Additionally, precision machining procedures for custom specifications can escalate prices. Factories that employ advanced manufacturing technologies may charge a premium, assuring higher quality and precision.

stud bolt m20 ราคา factories

3. Volume of Production The scale of production plays a significant role in pricing. Larger orders may benefit from economies of scale, allowing factories to reduce per-unit costs. Conversely, smaller orders might incur higher prices due to the fixed costs associated with production runs, including labor and overhead expenses. Bulk purchasing is often encouraged in the industry to minimize costs.

4. Market Demand and Supply Like any commodity, the price of M20 stud bolts can fluctuate based on market dynamics. If demand outstrips supply, prices are likely to rise. Conversely, in times of surplus production, manufacturers may lower prices to stimulate sales. Tracking industry trends and forecasts can provide insight into anticipated pricing changes.

5. Transport and Logistics The allocation of resources for shipping and transportation can also impact the end price of M20 stud bolts. Factories located in regions close to resource suppliers may benefit from lower logistics costs, allowing for competitive pricing. Conversely, manufacturers relying on imported materials or those with lengthy supply chains may have to account for higher transport expenses in their pricing.

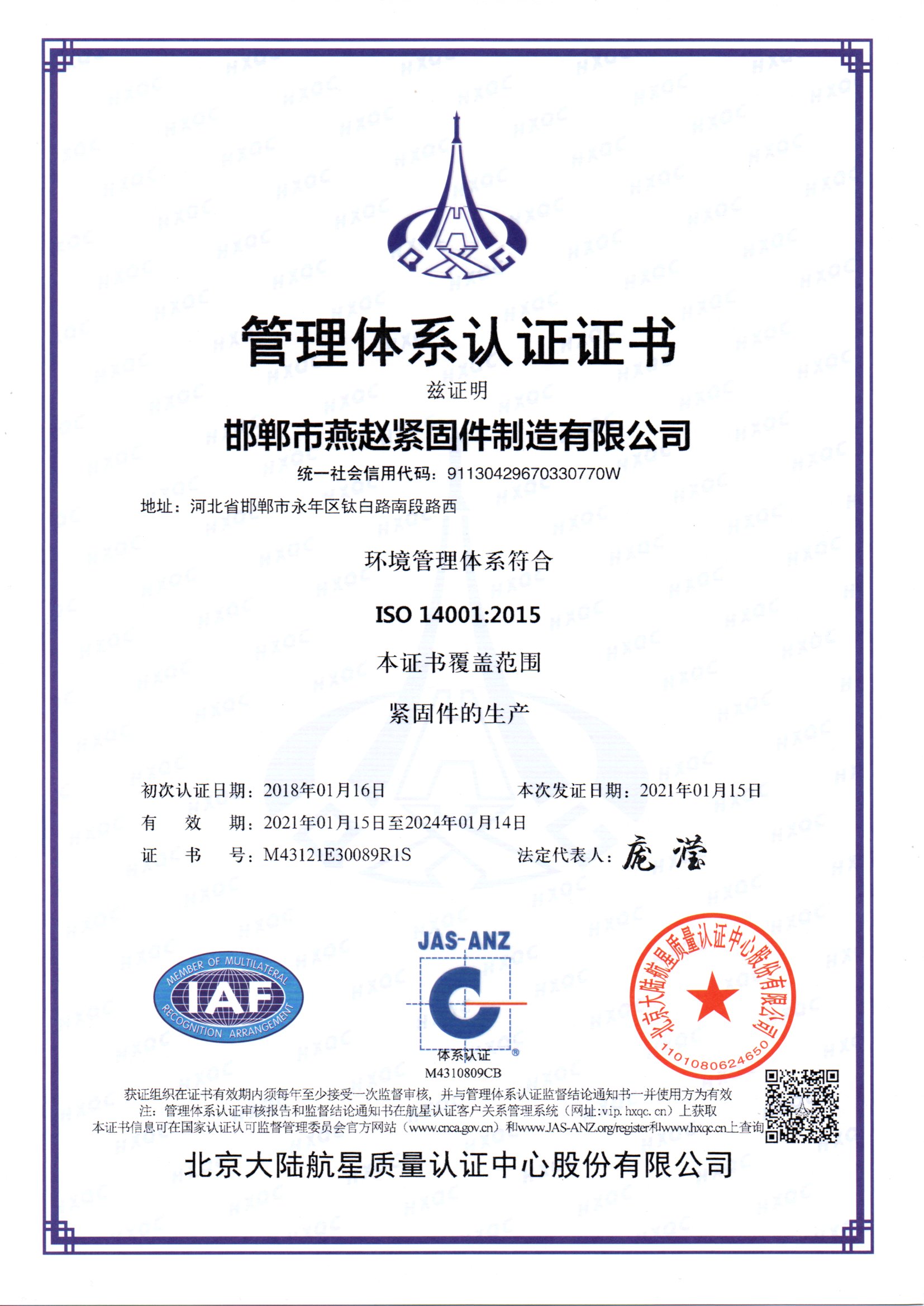

6. Quality Standards and Certifications High-quality products often adhere to various national and international standards, such as ISO certifications. Factories that meet these stringent quality requirements may impose additional fees reflective of the certifications and the quality assurance processes involved. Buyers are often willing to pay more for certified products as they ensure safety and reliability, particularly in critical industries like aerospace and construction.

Conclusion

The cost of M20 stud bolts from factories can vary significantly due to a plethora of factors, including material composition, manufacturing processes, order volume, market dynamics, logistics, and quality standards. Buyers are encouraged to consider not just the price but also the specifications and quality assurance when sourcing these components. By understanding the fundamentals influencing prices, companies can make more informed purchasing decisions, ultimately enhancing their supply chain efficiency and product reliability. Investing in high-quality M20 stud bolts can save costs in the long run by minimizing failures, ensuring safety, and enhancing overall performance in various applications. As industries continue to evolve, staying abreast of these factors will be essential for achieving optimal results in manufacturing and engineering.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025