stud bolt & exporter

Dec . 12, 2024 14:02 Back to list

stud bolt & exporter

Stud Bolts and Their Role in Exporting Industries

In the realm of manufacturing and construction, fasteners play a crucial role in ensuring the structural integrity and safety of various applications. Among the numerous types of fasteners, stud bolts stand out due to their versatility and reliability. This article will explore the significance of stud bolts, their applications in different industries, and how they contribute to the exporting sector.

Understanding Stud Bolts

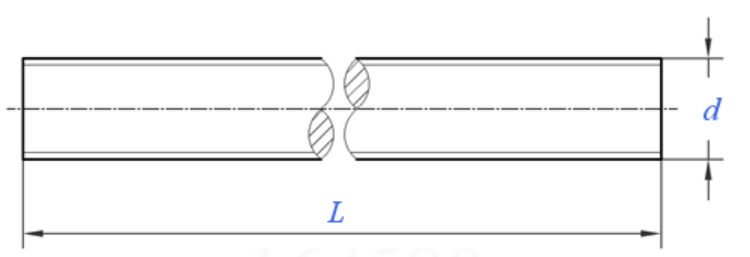

A stud bolt is a type of fastener that features a cylindrical rod with threads on both ends, designed to be used with nuts. Unlike traditional bolts that have a head on one end, stud bolts are advantageous for high-strength applications where space can be an issue. Typically made from materials such as carbon steel, stainless steel, or alloy steel, stud bolts can endure extreme temperatures and harsh environments, making them ideal for various industrial applications.

Applications of Stud Bolts

Stud bolts are widely used in several critical sectors, including oil and gas, construction, and manufacturing. In the oil and gas industry, these fasteners are essential for assembling flanged connections in pipelines and pressure vessels, which often encounter high pressure and corrosive substances. The strength and resistance to environmental factors make stud bolts a preferred choice for ensuring the safety and efficiency of these systems.

In construction, stud bolts are used in structural applications, such as securing beams, columns, and machinery foundations. Their ability to provide consistent tension makes them integral in maintaining the stability of large structures, especially in seismic regions where resilience to movement is necessary.

Manufacturers also rely heavily on stud bolts for assembling machinery and equipment where a robust and reliable fastening solution is required. Whether in automotive, aerospace, or general manufacturing, stud bolts ensure that components remain securely fastened throughout the operational lifespan of the equipment.

stud bolt & exporter

The Exporting Sector

The global demand for stud bolts has positioned them as a significant commodity in the exporting sector. Countries that specialize in manufacturing these fasteners often cater to international markets, supplying various industries with essential components. This trade not only boosts the economies of these manufacturing hubs but also fosters international collaborations and technological exchanges.

Moreover, as industries expand into emerging markets, the need for quality fasteners like stud bolts increases. This surge in demand provides opportunities for manufacturers to engineer innovative products that comply with international standards, enhancing their competitiveness in the global marketplace.

Quality Standards and Regulations

Exporting stud bolts involves adhering to stringent quality standards and regulations set by international organizations. The American National Standards Institute (ANSI), International Organization for Standardization (ISO), and other regulatory bodies establish specifications that ensure stud bolts meet the required strength, durability, and performance criteria. Manufacturers engaged in exporting must rigorously test their products to maintain compliance, ensuring that they can withstand the demands of various applications in different environments.

Conclusion

Stud bolts play an indispensable role in numerous industries, underpinning the safety and reliability of various applications. Their unique design and adaptability make them a preferred choice for structural and mechanical uses, particularly in high-stress environments. As the global market for such fasteners continues to grow, so too does the importance of compliance with quality standards to ensure safety and performance. The future of stud bolts in the exporting industry looks promising, with opportunities for innovation and market expansion on the horizon. As industries evolve, the enduring demand for high-quality fasteners will continue to drive the success of manufacturers worldwide.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025