Exporter for Stud Bolt 7 8 UNC Specifications and Quality Standards

Nov . 25, 2024 07:47 Back to list

Exporter for Stud Bolt 7 8 UNC Specifications and Quality Standards

Stud Bolt 7/8 UNC Exporter Understanding the Market and Choices

In the realm of industrial fastening, stud bolts have become vital components across various sectors, including construction, automotive, and manufacturing. Among the various specifications available, the 7/8 UNC (Unified National Coarse) stud bolt stands out due to its size and thread profile, making it a preferred choice in many applications that require sturdy and reliable fastening solutions. For businesses looking to procure or export these essential components, understanding the market dynamics, the importance of quality, and the selection of the right exporter are key aspects to consider.

Market Overview

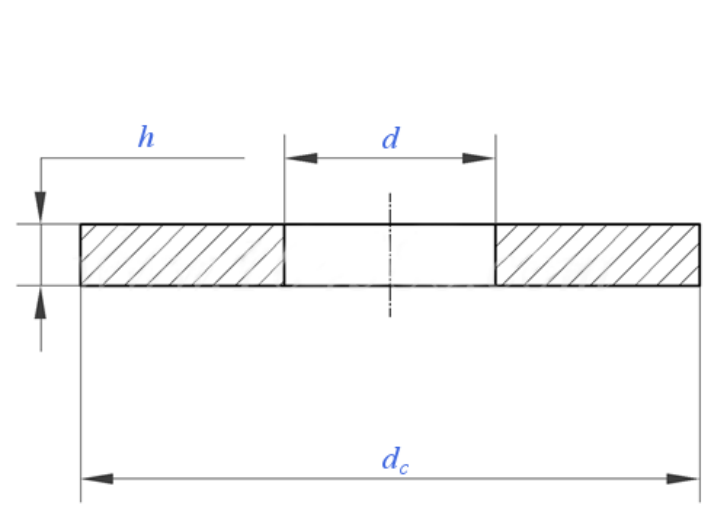

The global demand for stud bolts is closely tied to the growth of industries that rely on heavy machinery and structural applications. The 7/8 UNC stud bolt, characterized by its nominal diameter of 7/8 inch and coarse thread, is especially favored for its ability to provide strong tensile strength and durability. This specification is commonly used in various applications, from connecting structural steel components to fastening equipment in automotive manufacturing lines. The prominence of these bolts highlights the growing importance of export opportunities in a connected global economy.

Quality Assurance

When selecting an exporter for 7/8 UNC stud bolts, quality assurance stands as a non-negotiable criterion. High-quality stud bolts are manufactured under stringent industry standards, typically conforming to ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) regulations. These manufacturing standards ensure that each stud bolt can withstand significant loads and resist corrosion, which is crucial for applications in demanding environments. As a result, businesses should verify that their chosen exporter provides detailed certifications indicative of compliance with these standards.

stud bolt 7 8 unc exporter

Material Considerations

Another pivotal aspect of stud bolts is the material from which they are made. Common materials include carbon steel, stainless steel, and alloy steel, each offering different advantages in terms of strength, cost, and resistance to rust or wear. For instance, stainless steel stud bolts provide excellent resistance to corrosion, making them suitable for outdoor applications or in environments exposed to moisture. On the other hand, carbon steel options may represent a cost-effective solution for applications where weight considerations are less critical. Thus, exporters that offer a diverse range of materials empower buyers to make informed decisions tailored to their specific needs.

Customization and Responsiveness

Moreover, a reputable exporter should also offer customization options. This could involve catering to specific lengths, head types, or coatings that may be required for unique applications. The ability to provide customized solutions can enhance a business's operational capabilities significantly. Equally important is the exporter’s responsiveness and customer service. A responsive supplier can address questions promptly, provide technical support, and assist in navigating logistical challenges—an invaluable asset in international trade.

Conclusion

In conclusion, the global market for stud bolts, particularly the 7/8 UNC specification, presents numerous opportunities for exporters and importers alike. Companies seeking to import these vital components must carefully consider factors such as quality assurance, material options, and the capacity for customization. Engaging with a reliable exporter who aligns with these values can facilitate not only the procurement of high-quality products but also foster long-term business relationships. As industries continue to evolve, the need for strong, dependable fastening solutions like the 7/8 UNC stud bolt will undoubtedly persist, making adept navigation of this market both a challenge and a promising venture.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025