square head bolts and nuts manufacturer

Nov . 11, 2024 10:01 Back to list

square head bolts and nuts manufacturer

Square Head Bolts and Nuts Manufacturer Key Insights into Quality and Innovation

In the realm of industrial hardware, square head bolts and nuts have carved a niche for themselves as essential components for a variety of applications. Whether in construction, automotive, or manufacturing, these fasteners offer unique advantages that cater to specific needs. As the demand for durable and reliable fasteners continues to rise, manufacturers are evolving to meet these challenges, with an emphasis on quality, innovation, and sustainability.

Understanding Square Head Bolts and Nuts

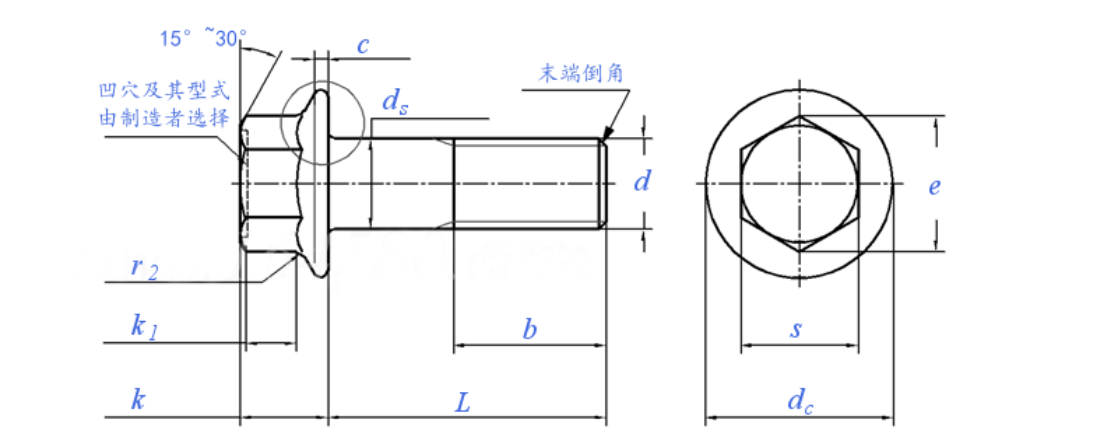

Square head bolts, characterized by their distinct square-shaped heads, are specifically designed to prevent rotation during fastening, allowing for a secure connection in high-stress environments. When paired with square nuts, these fasteners provide added stability and ease of use, making them ideal for woodwork, metal fabrication, and heavy machinery assembly.

The choice of square head bolts and nuts is often influenced by their aesthetic appeal and functional attributes. They are commonly used in architectural designs where a classic look is desired, as well as in applications where a firm grip is crucial. The square shape provides more surface area for tools, enabling better torque application compared to traditional round-headed bolts.

The Role of Manufacturers

Dedicated manufacturers of square head bolts and nuts play a crucial role in ensuring not only the availability but also the quality of these essential hardware items. Such manufacturers invest in advanced machinery and innovative production techniques to produce fasteners that meet stringent industry standards. This involves using high-grade materials such as carbon steel, stainless steel, and alloy steel, which guarantee durability and resistance to corrosion.

Quality control processes are paramount in the manufacturing of square head bolts and nuts. Reputable manufacturers conduct rigorous testing of their products, including tensile tests, hardness tests, and dimensional checks, to ensure that every fastener meets the specifications required by their clients. This commitment to quality helps prevent failures in critical applications where structural integrity is paramount.

square head bolts and nuts manufacturer

Innovations in Fastener Manufacturing

Innovation is a driving force in the fastener industry, with manufacturers continuously seeking ways to improve their products and processes. Recent advancements include the introduction of eco-friendly manufacturing practices that reduce waste and energy consumption. The shift towards sustainable materials and processes not only benefits the environment but also appeals to a growing base of eco-conscious consumers.

Additionally, manufacturers are exploring the integration of technology into the production of square head bolts and nuts. This includes the use of automation and robotics, which enhance precision, reduce production times, and minimize the likelihood of human error. By adopting smart manufacturing solutions, companies can achieve higher efficiency and consistently deliver high-quality products to their customers.

Customization and Application Versatility

One of the notable trends in the square head bolt and nut manufacturing sector is the rise of customization. Many manufacturers now offer tailored solutions to meet the specific needs of different industries. This means that customers can request variations in size, material, finish, and even coating processes. Such flexibility ensures that the fasteners provided are not only suitable for the intended application but also enhance performance and reliability.

Square head bolts and nuts are versatile and can be employed in a range of applications. From securing structural beams in construction to fastening components in industrial machinery, these fasteners play an integral role in the functionality and safety of various products. Their design makes them especially suitable for high-torque applications, which is why they are often found in equipment subjected to heavy loads.

Conclusion

In conclusion, the world of square head bolts and nuts is characterized by ongoing innovation, quality manufacturing, and a commitment to meeting the diverse needs of consumers. As the industry continues to evolve, manufacturers are embracing new technologies and sustainable practices to produce fasteners that not only meet but exceed expectations. By prioritizing quality and customization, square head bolt and nut manufacturers position themselves as vital players in the ever-demanding landscape of industrial hardware. Their contributions ensure that businesses and projects across the globe can rely on safe, durable, and efficient fastening solutions. As we look to the future, the importance of these components and their manufacturers will undoubtedly remain significant in shaping the landscape of construction and manufacturing.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025