spring washer manufacturing plant specializing in high-quality fasteners and custom solutions for various industries

Jul . 29, 2024 23:11 Back to list

spring washer manufacturing plant specializing in high-quality fasteners and custom solutions for various industries

The Importance of Spring Washer Factories in Modern Manufacturing

In the realm of modern manufacturing, precision and reliability are paramount. One crucial component that often goes unnoticed yet plays a vital role in various applications is the spring washer. This small but essential fastener aids in distributing loads, absorbing vibrations, and preventing loosening of other components. Spring washer factories, therefore, serve a significant role in supplying high-quality products that meet the rigorous demands of diverse industries.

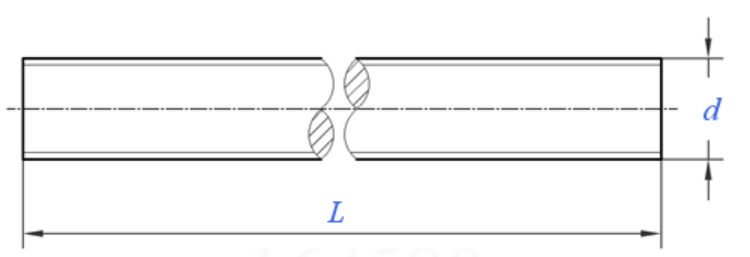

Spring washers, notably the split type, are designed with a unique curvature that allows them to exert a spring force when compressed. This characteristic is particularly beneficial in applications where securing threaded fasteners is necessary. The mechanical properties of spring washers ensure that they maintain tension under various conditions, reducing the risk of equipment failure and extending the lifespan of the assembled components.

The Importance of Spring Washer Factories in Modern Manufacturing

Quality control is another fundamental aspect of a spring washer factory's operations. Given the critical functions that spring washers serve, manufacturers often adhere to stringent industry standards, such as ISO 9001, to guarantee product reliability. Rigorous testing—such as tensile tests, hardness tests, and dimensional checks—are conducted to ensure that the washers meet the required mechanical properties and specifications. This commitment to quality is vital in industries such as automotive, aerospace, and construction, where failure to perform can lead to catastrophic consequences.

spring washer factory

Moreover, the rise of customization in manufacturing has significantly influenced the operations of spring washer factories. As industries evolve and demand unique specifications, manufacturers are increasingly offering tailored solutions, providing flexibility in terms of size, material, and design. This customization allows engineers and designers to optimize their projects, ensuring that each component is precisely suited for its intended application. Materials such as stainless steel, carbon steel, and other alloys are commonly used, chosen for their strength and resistance to corrosion, enhancing the longevity of the washers in challenging environments.

In response to environmental concerns, many spring washer factories are also adopting sustainable practices. This includes utilizing recyclable materials, reducing waste during production, and implementing energy-efficient processes. By focusing on sustainability, these factories are not only contributing to environmental conservation but also positioning themselves competitively in a market that increasingly values eco-friendly practices.

As technology advances, the future of spring washer manufacturing looks promising. Innovations like automation and artificial intelligence are starting to play a crucial role in enhancing efficiency and reducing production costs. These technological advancements allow factories to increase output while maintaining high-quality standards, ensuring that they can meet the ever-growing demand for fasteners across various sectors.

In conclusion, spring washer factories are integral to modern manufacturing, providing essential components that enhance the performance and safety of machinery and equipment. Their commitment to quality, customization, and sustainability has positioned them as vital players in the global manufacturing landscape. As industries continue to advance, the importance of spring washers, and consequently the factories that produce them, will only continue to grow.

Latest news

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025