sheet metal screws in wood exporter

Dec . 03, 2024 17:30 Back to list

sheet metal screws in wood exporter

The Export of Sheet Metal Screws in Wood A Growing Market

In recent years, the global demand for sheet metal screws has seen considerable growth, particularly in applications related to woodworking. Sheet metal screws, known for their versatility and strength, play a crucial role in joining materials, making them essential components in various industries, including construction, furniture manufacturing, and DIY projects. As an exporter of these screws, understanding the market dynamics and the factors driving demand is key to carving out a successful niche.

Understanding Sheet Metal Screws

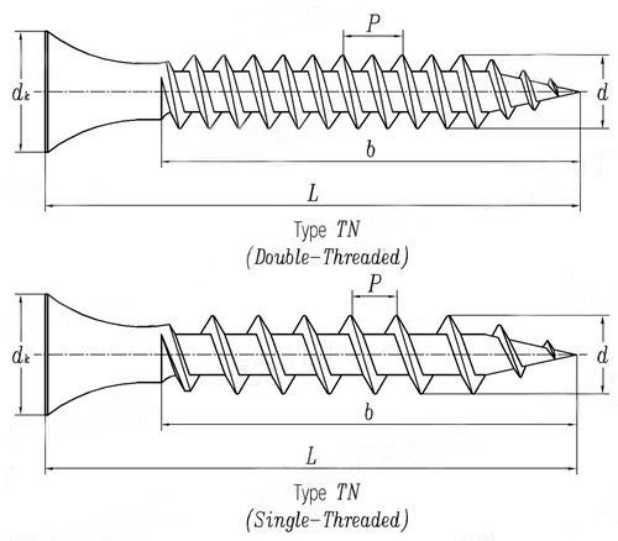

Sheet metal screws are designed to fasten metal sheets and other materials together, but their applications extend well into woodworking. They have a sharp point that allows them to penetrate wood surfaces easily, while their threaded design facilitates a secure hold. This versatility makes them an attractive option for manufacturers and craftsmen alike. They come in various sizes, materials, and finishes, allowing for tailored applications across different projects.

Reasons for Growing Demand

1. Rise in Construction and Renovation Projects The construction industry has been witnessing a boom, particularly in developing regions. With the increase in both commercial and residential projects, the need for reliable fastening solutions has surged. Sheet metal screws offer a robust solution for various applications, including drywall installation, roofing, and framing, which are all prevalent in construction.

2. DIY Culture The DIY movement has gained traction, with more individuals taking on woodworking projects at home. From furniture making to home improvements, the demand for quality fasteners like sheet metal screws has increased. Exporters tapping into this trend can meet the growing need for easily accessible and reliable fastening solutions that consumers can use in their projects.

3. Technological Advancements Innovations in manufacturing processes have led to the production of high-quality screws that provide better grip and durability. Coatings such as zinc or epoxy further enhance the corrosion resistance of screws, making them suitable for outdoor applications. Exporters focusing on quality and innovation will find a more receptive audience in both domestic and international markets.

sheet metal screws in wood exporter

4. Sustainability Trends As industries move toward more sustainable practices, there is a growing preference for materials that reduce environmental impact. Exporters of sheet metal screws can cater to this demand by offering products that are recyclable or made from sustainable sources.

Key Markets for Export

While North America and Europe remain significant markets for sheet metal screws, emerging economies in Asia and Africa present vast opportunities. With improving infrastructure and a burgeoning middle class, these regions are witnessing increased demand for construction supplies. Exporters should focus on developing relationships with distributors and manufacturers in these areas to capitalize on the growing market potential.

Challenges and Considerations

Despite the positive market trends, exporters face challenges such as strict regulations, competition from local manufacturers, and fluctuating material costs. Ensuring compliance with international standards and meeting specific customer requirements are crucial for success. Additionally, establishing a reliable supply chain and logistics framework can mitigate risks associated with delays and quality control.

Conclusion

The export market for sheet metal screws in woodworking is on the rise, driven by construction growth, DIY trends, technological innovations, and sustainability concerns. By understanding the evolving market landscape and addressing the challenges, exporters can secure their place in this competitive industry. With quality products and strategic market positioning, there is significant potential for growth and success in the export of sheet metal screws.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025