Rivets and Fasteners Suppliers for Your Construction Needs

Oct . 18, 2024 12:43 Back to list

Rivets and Fasteners Suppliers for Your Construction Needs

Rivnuts and Bolts Suppliers A Guide to Choosing the Right Manufacturer

In today's fast-paced manufacturing and construction industries, the importance of reliable fasteners cannot be overstated. Rivnuts, also known as blind rivet nuts, are versatile fasteners that provide a robust solution for joining components, especially in applications where access to the back of the material is restricted. Whether you're an engineer, contractor, or DIY enthusiast, understanding how to choose the right rivnuts and bolts suppliers is critical to the success of your projects.

Understanding Rivnuts A Quick Overview

Rivnuts are a type of fastener that can be installed in thin-walled materials, such as metal or plastic. They provide a strong threaded insert that allows for easier assembly and disassembly of parts, making them ideal for applications in automotive, aerospace, and furniture industries. The advantage of using rivnuts is their ability to create a strong, permanent thread in materials that would otherwise be challenging to work with.

The Role of Suppliers

When it comes to sourcing rivnuts and bolts, selecting the right supplier is crucial. Quality, variety, and customer service are key factors that can influence your decision. A reputable supplier should offer an extensive range of products, including different materials, sizes, and finishes to cater to various applications. Whether you require steel, aluminum, or brass rivnuts, having a wide selection will save you time and ensure you get the right product for your needs.

Key Factors to Consider When Choosing Rivnuts Suppliers

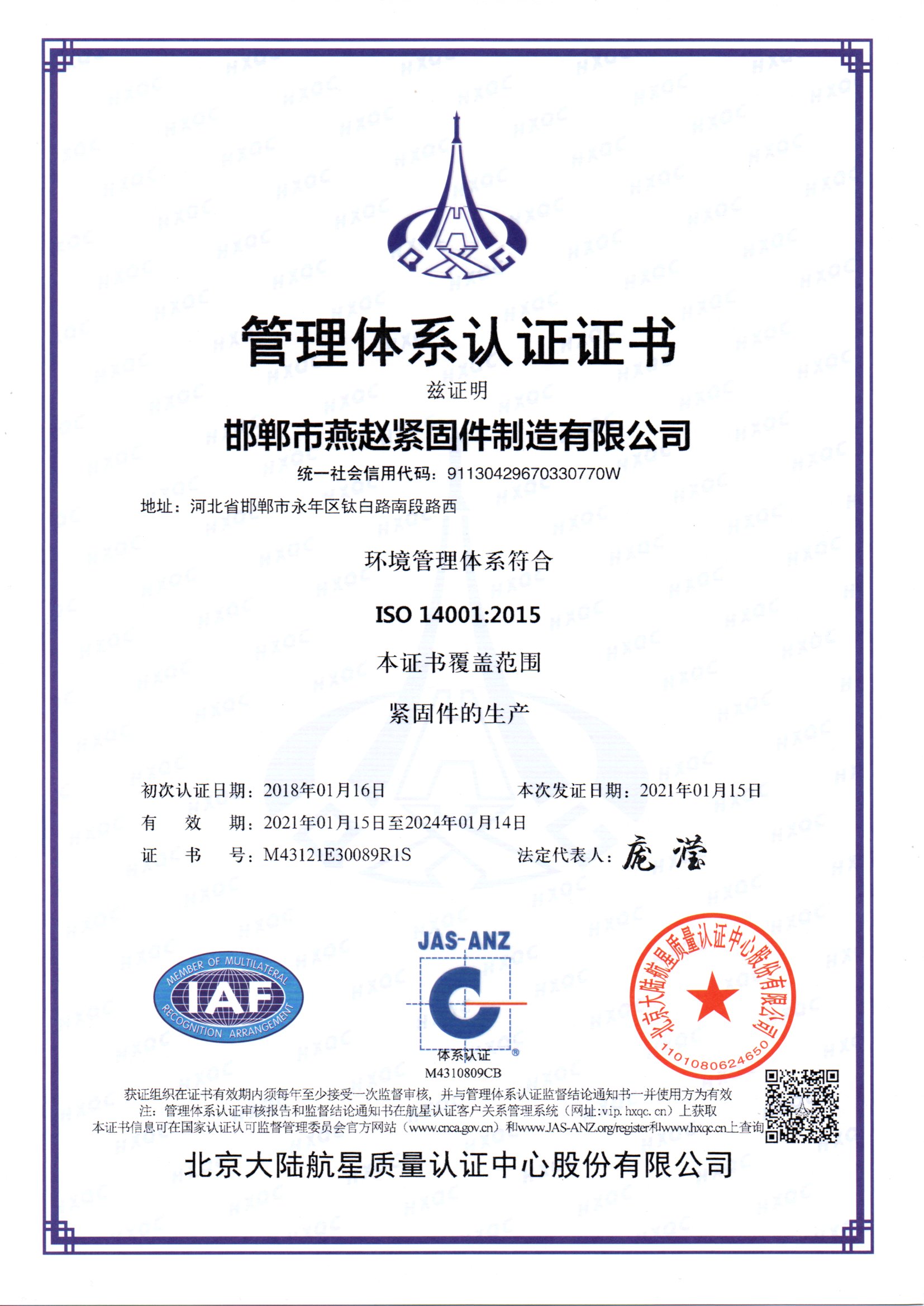

1. Quality of Products Superior quality is non-negotiable when it comes to fasteners. Look for suppliers that adhere to industry standards and have certifications such as ISO 9001, which indicate a commitment to quality management. Reading customer reviews and testimonials can also provide insights into the reliability of their products.

riv nuts and bolts suppliers

2. Variety of Products As projects vary significantly in requirements, it is essential to choose suppliers that stock a diverse range of rivnuts, including different sizes, materials, and finishes. This variety will help in ensuring you find the perfect fit for your application without needing to compromise on quality or performance.

3. Cost-Effectiveness While quality is paramount, cost is also a critical factor. Compare prices from different suppliers but be mindful of the total cost, which includes shipping and handling. Sometimes, cheaper options might not provide the long-term durability you need, leading to higher overall costs due to failures or replacements.

4. Customer Support A responsive customer support team can make all the difference when you're in need of urgent assistance or clarification on products. Choose suppliers who offer efficient communication channels, such as phone support, email, or live chat, ensuring you get help when you need it.

5. Delivery Times Fast and reliable delivery is crucial, especially for time-sensitive projects. Suppliers who can guarantee prompt shipping and have logistic partners to ensure safe delivery will significantly reduce the risk of project delays.

6. Reputation and Experience Suppliers with extensive industry experience tend to be more reliable. They understand the demands of various sectors and can provide valuable advice on the best products to suit your projects.

Conclusion

Choosing the right rivnuts and bolts suppliers can greatly impact the success of your operations. By considering factors like product quality, variety, pricing, customer support, delivery times, and supplier reputation, you can make an informed decision. Investing time in researching suppliers will not only help you find the best fasteners for your needs but will also foster a long-term partnership that benefits your business in the long run. Whether you're working on a large-scale project or a small DIY task, the right supplier can make all the difference in ensuring your success and satisfaction.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025