pressure plate bolts

Nov . 04, 2024 04:20 Back to list

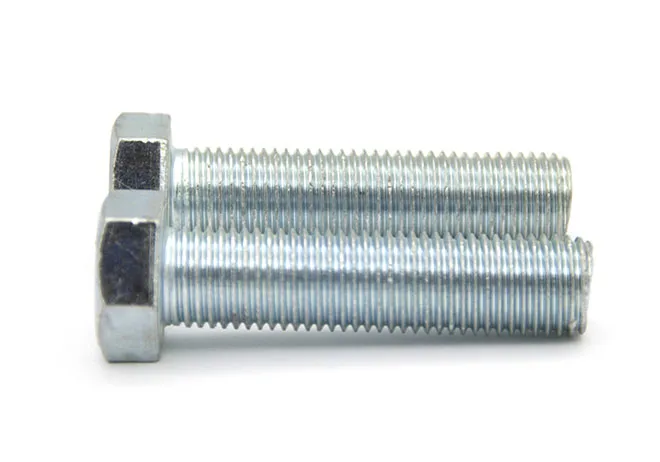

pressure plate bolts

Understanding Pressure Plate Bolts Importance, Types, and Maintenance

Pressure plate bolts are critical components in various mechanical systems, particularly in automotive and industrial applications. They play a vital role in ensuring the secure assembly of pressure plates, which are integral to clutch systems in vehicles, as well as in certain machinery where pressure management is essential. Understanding their significance, types, and maintenance can enhance both performance and safety.

Importance of Pressure Plate Bolts

The primary function of pressure plate bolts is to clamp the pressure plate against the flywheel or other components tightly. This secure connection is crucial in transferring torque from the engine to the transmission in automobiles. If the bolts are not adequately secured or maintain their tension under varying operational conditions, it can lead to slippage, reduced efficiency, or even catastrophic failure of the clutch system. Therefore, the quality and integrity of these bolts are paramount for maintaining optimal performance and ensuring safety.

Types of Pressure Plate Bolts

Pressure plate bolts come in various specifications, designed to meet different torque requirements and load-bearing capacities. Here are some common types

pressure plate bolts

1. High-Strength Bolts Often made from alloy steel, these bolts are heat-treated to enhance their tensile strength, making them suitable for high-performance applications where high torque is required. 2. Flanged Bolts These have a built-in washer that distributes the load over a larger area, providing better resistance to loosening from vibrations.

3. Shouldered Bolts These bolts are designed with a shoulder that provides additional support and can help in maintaining alignment during assembly.

4. Locking Bolts To prevent loosening due to vibration, locking mechanisms may be integrated, such as nylon inserts or mechanical locking features.

Maintenance of Pressure Plate Bolts

Proper maintenance is crucial for the longevity and performance of pressure plate bolts. Regular inspection for wear, corrosion, and proper torque is essential. Technicians should adhere to the manufacturer's specifications for torque settings when installing or reassembling pressure plates to ensure that bolts are neither too tight nor too loose. Additionally, when replacing pressure plates, it is generally advisable to replace the bolts as well, as the old bolts may have been compromised or may not meet the original tension specifications.

In conclusion, pressure plate bolts are small yet indispensable components in mechanical systems, particularly in the automotive sector. By understanding their importance, recognizing the various types available, and practicing proper maintenance, users can enhance the reliability and efficiency of their vehicles and machinery, ensuring safe and effective operation.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025