OEM Clinch Stud Bolt for Enhanced Performance and Durability in Industrial Applications

Nov . 09, 2024 05:56 Back to list

OEM Clinch Stud Bolt for Enhanced Performance and Durability in Industrial Applications

Understanding OEM Clinch Stud Bolts A Key Component in Modern Manufacturing

In today's fast-paced manufacturing environment, the importance of quality components cannot be overstated. One such critical component that plays a significant role in various applications is the OEM clinch stud bolt. This article delves into the features, benefits, applications, and the significance of OEM clinch stud bolts in modern manufacturing.

What is an OEM Clinch Stud Bolt?

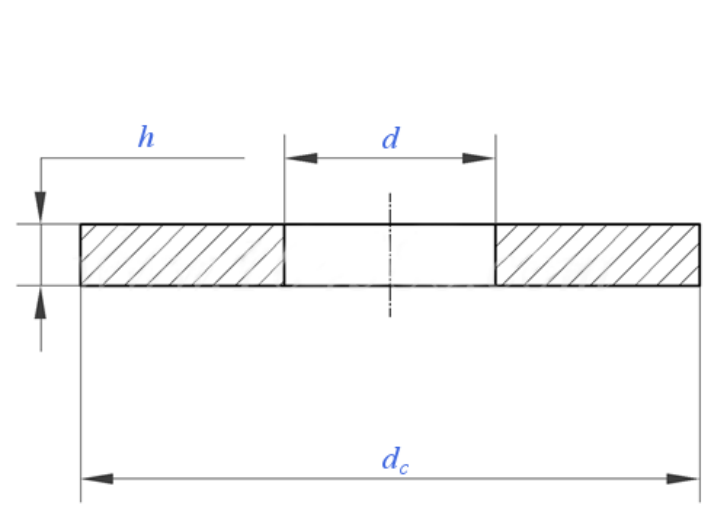

An OEM clinch stud bolt is a specialized fastener designed for heavy-duty applications where high strength and reliability are paramount. The term OEM stands for Original Equipment Manufacturer, indicating that these bolts are often produced to meet the stringent specifications of specific machinery or equipment. Clinch stud bolts are typically used in applications where welding or traditional fastening methods are not feasible, providing solutions that enhance structural integrity without requiring significant changes to the workpiece.

These bolts are characterized by a stud-like design with an integral head that can be pressed or clinched into a host material, forming a strong mechanical bond. The clinching process involves deforming the material around the bolt to create a secure fit, which is particularly advantageous in situations where space is limited, or where components are subjected to vibration and movement.

Features and Benefits

1. Durability and Strength OEM clinch stud bolts are made from high-grade materials, ensuring that they can withstand the rigors of industrial environments. Their robust construction provides excellent resistance to fatigue and stress, making them ideal for heavy machinery, automotive applications, and more.

2. Ease of Installation One of the standout features of clinch stud bolts is their ease of installation. Unlike traditional bolts that require multiple parts and tools, clinch bolts can often be installed using a single tool. This efficiency not only saves time but also reduces labor costs associated with fastening.

3. Vibration Resistance The design of clinch stud bolts helps to mitigate the issue of loosening due to vibrations. This makes them an excellent choice for applications involving equipment that experiences consistent movement, such as in automotive assembly or aerospace applications.

oem clinch stud bolt

4. Versatility These fasteners can be used in various materials, including metals, plastics, and composites. This versatility allows manufacturers to implement clinch stud bolts in different sectors, from automotive to consumer electronics.

5. Cost-Effectiveness While initial costs may vary, the overall expense associated with the use of OEM clinch stud bolts can be lower than that of traditional fastening methods. Reduced installation time and enhanced durability contribute to long-term savings.

Applications of OEM Clinch Stud Bolts

The applications for OEM clinch stud bolts are broad and varied. In the automotive industry, they can be found in everything from engine components to chassis frames, where strength and safety are non-negotiable. The aerospace sector also utilizes clinch bolts due to their lightweight and strong characteristics, making them suitable for aircraft assembly.

Beyond these industries, clinch stud bolts find their place in furniture manufacturing, electronics assembly, and construction projects. Their ability to securely fasten materials without adding significant weight has made them increasingly popular in these fields.

Conclusion

In conclusion, OEM clinch stud bolts represent a blend of strength, efficiency, and cost-effectiveness that is hard to match. Their unique design facilitates quick installation, reduces the risk of loosening, and enhances the durability of assembled components. As industries continue to evolve and demand higher standards for quality and performance, the importance of understanding and implementing reliable components like clinch stud bolts cannot be underestimated.

Manufacturers aiming for competitive advantage should consider the benefits of incorporating OEM clinch stud bolts into their production processes. The right fastener can make all the difference in achieving not only operational efficiency but also product reliability and safety. By leveraging the advantages of clinch stud bolts, companies can enhance their manufacturing capabilities and ensure superior outcomes in their respective fields.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025